Nitrocellulose Manufacturers

Our Nitrocellulose manufacturing factory in China stands out for its high-quality production, precision, and reliability. Our products are extensively used across various industries, including explosives, coatings, paints, and inks, ensuring superior performance and consistency. With a strong commitment to innovation and safety, we cater to the diverse needs of our global clients.

As a leading Nitrocellulose manufacturer in China, we pride ourselves on delivering high-quality products tailored to the needs of various industries. With advanced production facilities and stringent quality control processes, our Nitrocellulose is widely recognized for its superior purity, consistent performance, and reliability. Our expertise extends across multiple applications, including explosives, coatings, paints, and inks, ensuring that our customers receive the best possible solutions for their specific requirements.

Choosing us means partnering with a manufacturer committed to innovation, sustainability, and customer satisfaction. We offer competitive pricing, flexible delivery options, and dedicated customer support to meet the evolving demands of our global clientele. Our focus on continuous improvement and adherence to international standards positions us as a trusted partner for businesses seeking dependable and high-quality Nitrocellulose products. Additionally, we invest in research and development to stay at the forefront of technological advancements, enabling us to offer customized solutions that drive success in our customers’ operations.

Nitrocellulose FEATURES

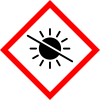

Nitrocellulose, commonly referred to as cellulose nitrate, is a versatile and highly flammable compound that plays a crucial role in various industrial applications. Known for its high solubility in organic solvents, Nitrocellulose is widely utilized in the manufacturing of explosives, coatings, paints, inks, and more. Its unique properties make it a preferred choice in industries requiring quick-drying and durable film formation. Nitrocellulose is valued for its ability to create strong bonds, offering excellent adhesion to various substrates while also providing a glossy finish.

High Energy Content

Nitrocellulose dissolves readily in organic solvents, making it an ideal component in lacquers and inks, ensuring smooth application and consistent performance.

Rapid Combustion

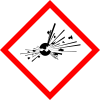

The compound's fast-burning nature ensures efficient and controlled explosive reactions, vital for applications in the defense and mining sectors.

Versatile Solubility

Nitrocellulose's solubility in a range of organic solvents enhances its usability across various industries, particularly in coatings and inks, where it serves as a film-forming agent.

Customizable Properties

The molecular structure of nitrocellulose can be modified to achieve desired levels of viscosity and nitrogen content, enabling tailored applications in different types of explosives and other products.

Stability and Safety:

Despite its reactive nature, nitrocellulose can be stabilized and safely handled under controlled conditions, ensuring its secure use in manufacturing environments.

Wide Industrial Application

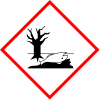

Beyond its role in explosives, nitrocellulose is also utilized in the production of lacquers, varnishes, and other industrial coatings, contributing to its wide-ranging applicability across multiple sectors.

Nitrocellulose SPECIFICATION

Our latest nitrocellulose batch demonstrates excellent quality across key parameters. The acetone insolubles are impressively low at 0.003%, well below the maximum limit of 0.4%. The ash content is also within standards, at 0.05%. Our ether/alcohol solubility measures 37.1, meeting the necessary requirements. We achieved a fineness of 96 ml, and while the moisture content is slightly higher at 33.2%, it remains acceptable. The nitrogen content is precisely at 13.15%, and the viscosity is 9.8 mPa·s, both of which are within the specified ranges.

| Index | Norm | Measured value |

| Acetone insolubles, % not more | 0.4 | 0.003 |

| Ash, % not more | 0.4 | 0.05 |

| Ether/alcohol Solubility | 28~40 | 37.1 |

| Fineness, ml | 70~110 | 96 |

| Moisture (Preferred Value: 28.5) | 27~35 | 33.2 |

| Bergman junk stability test, ml No/g, not more | 2.5 | 1.8 |

| Nitrogen, % | 13.10~13.20 | 13.15 |

| Nitrogen content – Grade C Type 1 (Preferred Value: 13.15) | 13.10~13.20 | – |

| Viscosity, mPas (cP, 0E) Seconds | 9~15 | 9.8 |

Nitrocellulose applications

Nitrocellulose, also known as cellulose nitrate, is a highly versatile material with a wide range of applications across various industries due to its unique properties. Its ability to form films, its explosive potential, and its solubility in organic solvents make it an essential component in numerous products, from coatings and inks to explosives and propellants.

- Explosives and Propellants: Nitrocellulose is a key ingredient in the production of smokeless gunpowder and other explosives. Its ability to rapidly decompose and release gases under controlled conditions makes it ideal for use in ammunition, fireworks, and rocket propellants.

- Coatings: Nitrocellulose is widely used in the formulation of lacquers and varnishes due to its fast-drying properties and ability to create a durable, glossy finish. It is commonly used in automotive paints, wood finishes, and protective coatings for various surfaces.

- Printing Inks: In the printing industry, nitrocellulose serves as a primary binder in inks due to its excellent film-forming capability. It ensures good adhesion, quick drying, and a glossy finish, making it suitable for use in high-speed printing processes like gravure and flexography.

- Cosmetics Nitrocellulose: is used in the production of nail polishes where it acts as a film-former, providing a smooth and durable finish. Its ability to dissolve in solvents and form a strong, flexible film is crucial for creating high-quality nail care products.

- Adhesives: The adhesive industry utilizes nitrocellulose in certain formulations where quick setting and strong bonding are required. Its film-forming properties make it effective in bonding a variety of materials, including plastics, textiles, and metals.

- Celluloid Production: Nitrocellulose is the main component in the production of celluloid, an early form of plastic used in the manufacture of film, toys, and other items. Although largely replaced by modern plastics, nitrocellulose-based celluloid remains in use for specialty products such as table tennis balls and guitar picks.

Nitrocellulose faq

Methylcyclohexane is a clear, colorless liquid with a faintly sweet odor. It is an organic compound belonging to the cycloalkane family, with the molecular formula C7H14. This flammable hydrocarbon is commonly used as a solvent in various industrial applications, such as the production of rubber, lacquers, and resins. It also serves as a raw material for the synthesis of other organic compounds. Methylcyclohexane is known for its excellent solvent properties, making it a valuable substance in chemical processing. However, it is important to handle this compound with caution, as exposure to high concentrations can cause irritation to the eyes, skin, and respiratory system. Proper storage and handling procedures, including the use of well-ventilated areas and protective equipment, are essential to minimize potential health risks associated with methylcyclohexane.

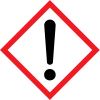

Safety is a priority when handling nitrocellulose. It must be stored in a cool, dry place, away from heat sources or open flames. Proper protective equipment, such as gloves and goggles, should be worn to minimize exposure and prevent accidents.

We offer a variety of nitrocellulose grades tailored to different industrial applications, including those with varying nitrogen content and viscosity levels. Our team can help you select the most suitable grade based on your specific needs.

Nitrocellulose is classified as a hazardous material and requires specialized packaging and documentation for transport. We ensure that all shipments comply with international safety regulations, providing peace of mind that your order will arrive safely and securely.

Yes, we can customize nitrocellulose formulations to meet the unique requirements of your application. Whether you need a particular viscosity, nitrogen content, or other specific properties, our experts can develop a solution that fits your needs.

Our nitrocellulose is manufactured to the highest quality standards, ensuring consistent performance across all applications. We use advanced production techniques and rigorous quality control to deliver a product that meets or exceeds industry benchmarks.

We implement rigorous quality control measures at every stage of production, from raw material selection to final product testing. Each batch of nitrocellulose undergoes comprehensive analysis to ensure it meets our stringent standards for purity, viscosity, and nitrogen content.

Yes, we offer bulk purchasing options to meet the needs of large-scale industrial operations. Our flexible supply chain allows us to accommodate orders of various sizes, ensuring that you receive the quantity of nitrocellulose required for your production schedule.

contact us

Looking to source high-quality Nitrocellulose? Contact us today! As a trusted manufacturer, we’re here to meet your needs for explosives, coatings, inks, and more. Let’s discuss how we can support your projects.