Carboxy Cellulose, a term broadly encompassing various derivatives of cellulose like Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, Microcrystalline cellulose, Hydroxyethyl cellulose, and Hydroxypropyl cellulose, stands at the forefront of cosmetic science. As a versatile and multifunctional ingredient, it has revolutionized the world of cosmetics and skin care.

Derived from natural cellulose, a primary structural component of plants, Carboxy Cellulose undergoes chemical modifications to enhance its properties. These modifications involve introducing carboxymethyl groups into the cellulose chain, resulting in a water-soluble and highly absorbent material, perfect for cosmetic applications.

The historical use of Carboxy Cellulose in cosmetics and skin care traces back several decades. It has been a staple in the formulation of a wide range of products, owing to its unique properties that cater to various needs in skin care. Over the years, its application has evolved, keeping pace with advancements in cosmetic science and consumer preferences.

One of the earliest uses of Carboxy Cellulose in cosmetics was as a thickening agent. Its ability to increase the viscosity of liquids made it an ideal choice for creams and lotions. Over time, its role expanded to include acting as a stabilizer and emulsifier, ensuring the consistency and efficacy of cosmetic products.

Today, Carboxy Cellulose and its derivatives like carboxymethylcellulose sodium are recognized not only for their functional roles but also for their skin-friendly properties. They are lauded for their ability to improve skin texture, provide hydration, and form protective barriers on the skin.

In conclusion, Carboxy Cellulose represents a key ingredient in the cosmetic industry, valued for its versatility, effectiveness, and alignment with the growing demand for natural and sustainable beauty solutions. As we delve deeper into its chemical and physical properties, its pivotal role in cosmetic formulations becomes increasingly evident.

Chemical and Physical Properties of Carboxy Cellulose

The diverse applications of Carboxy Cellulose in cosmetic formulations are rooted in its unique chemical and physical properties. Understanding these properties is key to appreciating its role in the beauty industry.

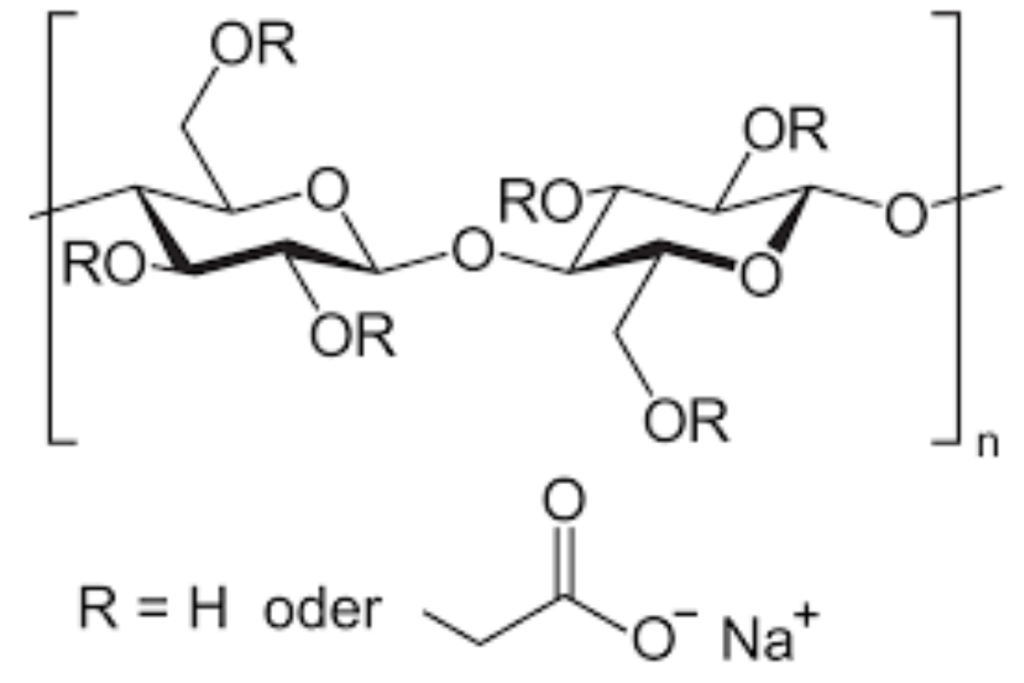

Detailed Exploration of the Chemical Structure of Carboxy Cellulose

Carboxy Cellulose, including variants like Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, and carboxymethylcellulose sodium, is a chemically modified form of cellulose. The process involves substituting hydroxyl groups in the cellulose molecule with carboxymethyl groups. This alteration significantly enhances its solubility in water, a trait that native cellulose lacks.

The degree of substitution and the molecular weight of Carboxy Cellulose can vary, which in turn influences its properties. For instance, a higher degree of substitution typically leads to increased solubility and viscosity. These variations allow for the customization of Carboxy Cellulose for specific uses in cosmetic formulations.

Physical Properties Relevant to Cosmetic Formulations

In terms of physical properties, Carboxy Cellulose is known for its high viscosity, which makes it an excellent thickening agent in creams, lotions, and gels. This viscosity is not just for textural purposes; it also aids in the even distribution and suspension of other ingredients within a formulation, ensuring consistency and stability.

Another notable property of Carboxy Cellulose is its film-forming ability. When applied to the skin, it can form a thin, breathable film that helps to retain moisture and protect the skin from environmental pollutants. This film-forming characteristic is particularly beneficial in barrier creams and hydrating serums.

Moreover, Carboxy Cellulose’s hygroscopic nature, meaning its ability to attract and hold water molecules, makes it an effective humectant. This property is crucial in skin care products aimed at hydrating and maintaining the skin’s natural moisture balance.

In conclusion, the chemical and physical properties of Carboxy Cellulose play a pivotal role in its effectiveness as a cosmetic ingredient. Its versatility, ability to enhance product texture and stability, and skin-hydrating properties make it an invaluable component in a wide range of cosmetic and skin care products.

Carboxy Cellulose in Cosmetic Formulations

Carboxy Cellulose, encompassing derivatives like Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, and carboxymethylcellulose sodium, plays a multifaceted role in cosmetic formulations. Its adaptability as a thickener, stabilizer, and emulsifier makes it a cornerstone ingredient in the cosmetic industry.

Role of Carboxy Cellulose as a Thickener, Stabilizer, and Emulsifier

As a thickening agent, Carboxy Cellulose contributes to the desired viscosity and texture of cosmetic products. Its ability to increase the thickness of liquids without altering other properties is essential in creams, lotions, and serums. This attribute not only improves the application experience but also influences the perception of product quality.

In terms of stabilization, Carboxy Cellulose helps maintain the uniformity and integrity of cosmetic products. It prevents the separation of ingredients in formulations, ensuring that the product remains consistent from the first use to the last. This stabilizing effect is particularly important in products with a high concentration of active ingredients or in those that are prone to separation due to temperature changes.

As an emulsifier, Carboxy Cellulose facilitates the blending of water and oil phases in cosmetic formulations. This emulsification is crucial for creating a homogenous mixture, ensuring that the product is smooth and even when applied to the skin.

Examples of Cosmetic Products that Utilize Carboxy Cellulose

The use of Carboxy Cellulose is widespread in the cosmetic industry. For instance, in facial moisturizers, it enhances the texture and stability, providing a smooth and non-greasy feel. In makeup products like foundations and BB creams, Carboxy Cellulose helps achieve the right consistency for easy application and lasting wear.

In hair care products, such as shampoos and conditioners, Carboxy Cellulose improves the product’s spreadability and ensures even distribution of conditioning agents on the hair. It also plays a role in styling products, where it contributes to the formulation’s hold and texture.

Additionally, in sunscreens, Carboxy Cellulose assists in forming a uniform protective layer on the skin, enhancing the effectiveness of sun-protective agents.

In conclusion, Carboxy Cellulose is a versatile and essential ingredient in a variety of cosmetic products. Its ability to improve texture, stability, and efficacy makes it a valuable asset in the formulation of high-quality cosmetic and skin care products.

Benefits of Carboxy Cellulose in Skin Care Products

The incorporation of Carboxy Cellulose and its derivatives, like Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, and carboxymethylcellulose sodium, into skin care products offers numerous advantages. These benefits range from enhancing skin hydration to improving texture and providing barrier protection.

Advantages for Skin Hydration, Texture Improvement, and Barrier Protection

Hydration is a key benefit of Carboxy Cellulose in skin care. Its hygroscopic nature allows it to attract and retain moisture, providing long-lasting hydration to the skin. This is particularly beneficial in moisturizers and serums, where maintaining skin moisture is crucial for a healthy and radiant complexion.

In terms of texture improvement, Carboxy Cellulose contributes to the smooth and silky feel of skin care products. Its ability to form a film on the skin’s surface leads to an immediate improvement in skin texture, making it appear more even and refined. This film-forming action also aids in filling in fine lines and wrinkles, giving the skin a more youthful appearance.

Carboxy Cellulose also plays a vital role in barrier protection. The film it forms on the skin acts as a protective barrier against environmental aggressors like pollutants and irritants. This barrier not only shields the skin but also enhances the efficacy of other active ingredients in the formulation by keeping them locked in and closer to the skin.

Comparison with Other Commonly Used Cosmetic Ingredients

Compared to other cosmetic ingredients, Carboxy Cellulose stands out for its natural origin and multifunctionality. While synthetic polymers can offer similar texturizing benefits, Carboxy Cellulose is preferred for its natural, non-irritating profile, making it suitable for all skin types, including sensitive skin.

Moreover, Carboxy Cellulose is often favored over other natural ingredients due to its consistency and stability in formulations. Its versatility allows it to be used in a wide range of product types, from light serums to rich creams, without compromising the product’s stability or efficacy.

In conclusion, Carboxy Cellulose is a valuable ingredient in skin care formulations, offering hydration, texture improvement, and protective benefits. Its comparison with other cosmetic ingredients highlights its unique properties and suitability for a wide range of skin care needs.

Carboxy Cellulose in Sustainable and Natural Cosmetics

The role of Carboxy Cellulose and its derivatives, such as Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, and carboxymethylcellulose sodium, is increasingly significant in the formulation of eco-friendly and natural cosmetic products. The push towards green chemistry and sustainable sourcing has highlighted the importance of Carboxy Cellulose in this sector.

Importance in the Formulation of Eco-Friendly and Natural Cosmetic Products

Carboxy Cellulose, derived from natural cellulose, is biodegradable and renewable, making it an attractive ingredient for sustainable cosmetic formulations. Its natural origin aligns with the growing consumer demand for eco-friendly products that are gentle on the skin and the environment.

In natural cosmetics, Carboxy Cellulose serves as an effective alternative to synthetic polymers and additives. Its functionality as a thickener, stabilizer, and emulsifier allows natural cosmetic formulations to achieve the desired consistency and efficacy without relying on potentially harmful synthetic ingredients.

Trends in Green Chemistry and Sustainable Sourcing of Carboxy Cellulose

The trend towards green chemistry in cosmetics emphasizes the use of ingredients that are safe, environmentally friendly, and sustainably sourced. Carboxy Cellulose fits this profile perfectly, as its production involves minimal environmental impact compared to the synthesis of many synthetic polymers.

Sustainable sourcing of Carboxy Cellulose is also a key consideration. The cellulose used in its production is typically derived from sustainably managed forests, ensuring that the environmental footprint is kept to a minimum. This responsible sourcing is crucial for maintaining the balance between meeting consumer needs and preserving natural resources.

In conclusion, Carboxy Cellulose plays a pivotal role in the world of sustainable and natural cosmetics. Its biodegradable nature, effectiveness as a cosmetic ingredient, and alignment with green chemistry principles make it a preferred choice in formulating environmentally responsible and skin-friendly products.

Technological Innovations and Emerging Trends

The use of Carboxy Cellulose and its derivatives in the cosmetic industry is constantly evolving, driven by technological innovations and emerging trends. These advancements are shaping the future of cosmetic formulations, making products more effective, sustainable, and tailored to consumer needs.

Recent Advancements in the Cosmetic Use of Carboxy Cellulose

Recent years have seen significant advancements in how Carboxy Cellulose, including Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, and carboxymethylcellulose sodium, is utilized in cosmetic products. Innovations in processing and formulation techniques have enabled the creation of more refined and effective Carboxy Cellulose derivatives. These advancements have improved the sensory attributes, stability, and efficacy of cosmetic products.

One of the key areas of innovation is in the development of Carboxy Cellulose-based gels and emulsions that offer enhanced skin-feel and longer-lasting hydration. Advanced processing techniques have also led to the creation of Carboxy Cellulose with varying molecular weights and degrees of substitution, allowing for more precise control over the product’s viscosity and texture.

Future Potential in Cosmetic Science and Technology

Looking ahead, the potential of Carboxy Cellulose in cosmetic science is vast. One promising area is the use of Carboxy Cellulose nanoparticles, which could offer new ways to deliver active ingredients more effectively into the skin. These nanoparticles can be designed to target specific layers of the skin, enhancing the absorption and efficacy of skincare actives.

Another emerging trend is the integration of Carboxy Cellulose in smart cosmetic formulations. These products can respond to environmental factors such as temperature and humidity, or to skin’s specific conditions, providing a personalized skincare experience.

Moreover, the drive towards sustainable and eco-friendly cosmetics continues to fuel research into Carboxy Cellulose. Innovations in sourcing and processing are aimed at minimizing environmental impact, aligning with the global trend towards green beauty.

In conclusion, the ongoing technological advancements and emerging trends in the use of Carboxy Cellulose are setting new standards in cosmetic science. These developments not only enhance the performance and appeal of cosmetic products but also pave the way for more personalized, effective, and sustainable skincare solutions.

Safety, Regulation, and Consumer Perception

The incorporation of Carboxy Cellulose and its derivatives, such as Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, and carboxymethylcellulose sodium, in cosmetics, is not only a matter of efficacy but also of safety and regulation. Understanding the consumer perception towards these ingredients is equally vital for the cosmetic industry.

Discussion on the Safety Profile and Regulatory Status of Carboxy Cellulose

Carboxy Cellulose is generally recognized for its high safety profile, making it a preferred ingredient in cosmetic formulations. It is non-toxic and typically does not cause irritation or allergic reactions, which is crucial in products applied to the skin. However, like all cosmetic ingredients, Carboxy Cellulose is subject to regulatory scrutiny.

In many regions, including the European Union and the United States, cosmetic ingredients are regulated to ensure they are safe for consumer use. Carboxy Cellulose and its derivatives must comply with these regulations, which cover aspects like purity, concentration levels, and permissible uses. Manufacturers are required to conduct rigorous testing to prove that products containing Carboxy Cellulose are safe and effective.

Consumer Trends and Perceptions Towards Carboxy Cellulose in Cosmetics

Consumer perception of Carboxy Cellulose in cosmetics plays a significant role in its acceptance and usage. In recent years, there has been a growing demand for products with natural and safe ingredients, and Carboxy Cellulose fits well into this trend due to its natural origin and non-toxic nature.

However, there are challenges in addressing consumer misconceptions and ensuring informed decisions. Clear communication and transparency about the role and safety of Carboxy Cellulose in products can help in building consumer trust. Education about the benefits and safety of Carboxy Cellulose, supported by scientific evidence, is key to changing any negative perceptions.

In conclusion, the safety, regulation, and consumer perception of Carboxy Cellulose are crucial elements in its continued use in cosmetic products. Ensuring regulatory compliance and addressing consumer concerns are essential for maintaining the integrity and success of Carboxy Cellulose in the cosmetic industry.

Challenges and Limitations in Cosmetic Applications

While Carboxy Cellulose and its derivatives, such as Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, and carboxymethylcellulose sodium, offer numerous benefits in cosmetic applications, they also come with certain challenges and limitations. Addressing these is crucial for optimizing their use and expanding their potential in the beauty industry.

Technical and Formulation Challenges

One of the primary technical challenges in using Carboxy Cellulose is achieving the right balance in formulations. The viscosity and texture imparted by Carboxy Cellulose need to be carefully controlled to meet the specific requirements of different cosmetic products. Excessive use can lead to overly thick or sticky formulations, which may not be appealing to consumers.

Compatibility with other ingredients is another challenge. Carboxy Cellulose must interact effectively with a range of other components in cosmetic formulations, including active ingredients, fragrances, and preservatives. Ensuring that these interactions do not affect the stability or efficacy of the product requires thorough testing and expertise in formulation chemistry.

Addressing Consumer Misconceptions and Scientific Challenges

Despite its benefits, there are misconceptions and concerns among some consumers regarding the use of Carboxy Cellulose in cosmetics, often stemming from a lack of understanding of its nature and function. Educating consumers about the safety and benefits of Carboxy Cellulose can help in dispelling these misconceptions.

From a scientific perspective, continuous research is needed to further understand the long-term effects of Carboxy Cellulose on the skin, especially in terms of absorption and potential irritation. Although generally considered safe, ongoing studies and monitoring are essential to ensure that Carboxy Cellulose remains a beneficial and non-harmful ingredient in cosmetic products.

In conclusion, while Carboxy Cellulose is a valuable ingredient in cosmetics, overcoming technical, formulation, and perceptual challenges is key to maximizing its benefits. Through research, innovation, and consumer education, the potential of Carboxy Cellulose in cosmetic applications can be fully realized, ensuring its continued success in the beauty industry.

In summarizing the role and significance of Carboxy Cellulose in cosmetic and skin care applications, it’s clear that this ingredient, along with its derivatives like Carboxymethyl cellulose (CMC), Sodium carboxymethyl cellulose, and carboxymethylcellulose sodium, has become a linchpin in modern cosmetic formulations. Its multifunctional capabilities have not only enhanced the quality of numerous beauty products but also aligned with the evolving trends of natural and sustainable cosmetics.

The journey of Carboxy Cellulose from a simple thickening agent to a key player in cosmetic science mirrors the industry’s progression towards more innovative, safe, and consumer-friendly products. Its role in enhancing product texture, stability, and user experience, while ensuring safety and sustainability, is a testament to its versatility and efficacy.

Looking ahead, the future of Carboxy Cellulose in the beauty industry appears promising. As technological advancements continue, and as consumer awareness and demand for natural and eco-friendly products grow, Carboxy Cellulose is poised to play an even more significant role. The potential for new formulations, smarter applications, and greener production methods opens up a realm of possibilities for this humble yet powerful ingredient.

In conclusion, Carboxy Cellulose stands as a crucial component in the cosmetic and skin care industries. Its continued evolution and application in beauty products will undoubtedly contribute to the development of more effective, sustainable, and consumer-friendly cosmetic solutions, maintaining its status as an indispensable asset in the world of beauty and personal care.