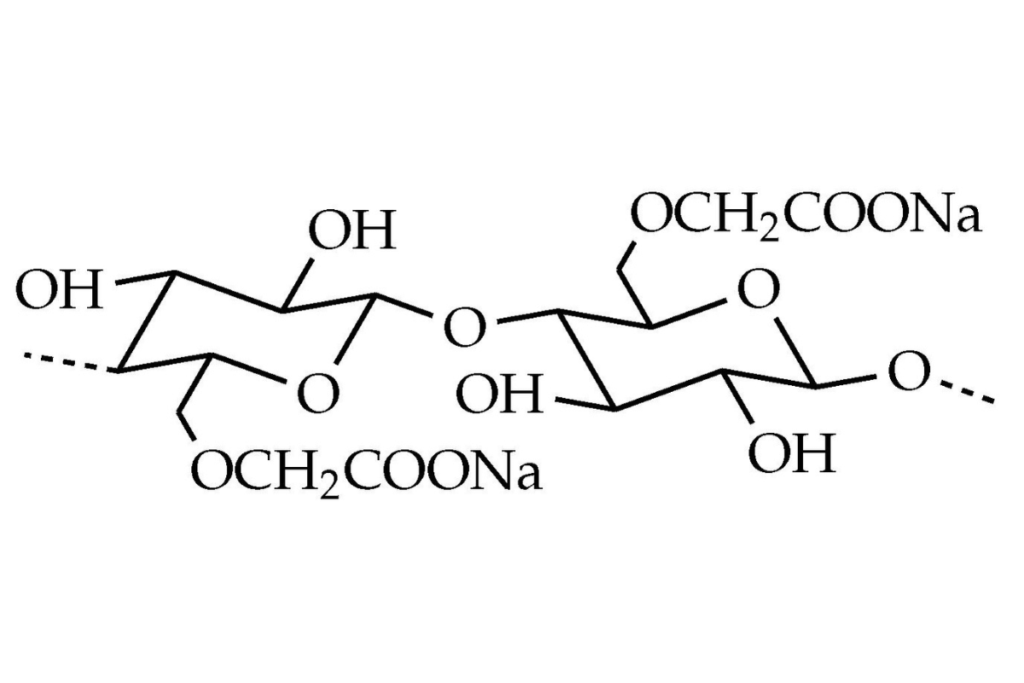

Carboxymethy cellulose (CMC), also known as sodium carboxymethy cellulose or carboxymethylcellulose sodium, is a chemically modified derivative of cellulose. In its essence, CMC is a cellulose ether, where the hydroxyl groups of the glucopyranose monomers are partially substituted with carboxymethyl groups (-CH2-COOH). This modification imparts unique properties to CMC, including water solubility, which is not typically found in cellulose.

Carboxymethyl cellulose is distinct from related compounds such as microcrystalline cellulose and hydroxypropyl cellulose, each having unique functional groups and properties. CMC’s specific structure allows it to interact with water, forming a viscous solution, which is a key attribute leveraged in various applications.

The history of CMC dates back to the early 20th century, initially finding applications in the textile and paper industries as a thickening agent. Its transition into biomedical applications began much later, as researchers discovered its biocompatibility and versatility. Over the years, CMC has evolved significantly, expanding its utility across multiple industries, including food, pharmaceuticals, and more recently, biomedicine.

In the biomedical field, CMC’s journey is marked by its growing importance in drug delivery systems, wound care, and tissue engineering. The evolution of CMC in these areas highlights not only the adaptability of this compound but also the expanding scope of biocompatible materials in medical science.

Properties of Carboxymethy Cellulose Relevant to Biomedical Applications

Key Physical and Chemical Properties of Carboxymethy Cellulose

Carboxymethy cellulose (CMC), distinct from its counterparts like microcrystalline cellulose and hydroxypropyl cellulose, possesses a set of unique physical and chemical properties that make it particularly suitable for biomedical applications. One of the most notable properties of CMC is its high water solubility, a trait that is rare in native cellulose. This solubility is attributed to the carboxymethyl groups (-CH2-COOH) attached to the cellulose backbone, which enhance its ability to interact with water molecules.

Another critical property of CMC is its viscosity. When dissolved in water, CMC solutions can exhibit a wide range of viscosities, depending on the concentration and degree of substitution of the carboxymethyl groups. This variability in viscosity allows for the tailoring of CMC-based materials to specific medical applications, such as drug delivery systems and wound dressings.

The biocompatibility of CMC is also a key characteristic, making it safe for use in biomedical contexts. Unlike some synthetic polymers, CMC does not elicit a significant immune response, making it suitable for applications that require direct contact with biological tissues.

How These Properties Make Carboxymethy Cellulose Suitable for Biomedical Uses

The water solubility and adjustable viscosity of CMC are crucial in drug delivery applications. These properties enable the formation of hydrogels, which can be used to encapsulate drugs, allowing for controlled release over time. This controlled release is essential for maintaining therapeutic drug levels in the body, minimizing side effects, and improving patient compliance.

In wound care, the hydrophilic nature of CMC helps in absorbing exudate, keeping the wound environment moist, which is conducive to healing. The gel-like consistency formed by CMC upon contact with wound exudates also provides a protective barrier, reducing the risk of infection and aiding in pain management.

The biocompatibility of CMC is another significant advantage in biomedical applications. Its compatibility with biological tissues makes it an excellent candidate for use in medical implants and tissue engineering. In these applications, CMC can serve as a scaffold, supporting cell growth and tissue regeneration.

Carboxymethy Cellulose in Drug Delivery Systems

Role of Carboxymethy Cellulose in Controlled Drug Release

In the realm of drug delivery, Carboxymethyl cellulose (CMC) plays a pivotal role, primarily due to its capacity for controlled drug release. This characteristic of CMC is fundamentally rooted in its water-soluble nature and the ability to form hydrogels. When used in drug delivery systems, CMC can encapsulate active pharmaceutical ingredients, creating a matrix that releases the drug in a controlled manner. This control is crucial for maintaining therapeutic drug levels in the body, which is essential for the efficacy of the treatment and minimization of side effects.

The viscosity of CMC-based hydrogels can be precisely adjusted, which directly influences the rate of drug release. Higher viscosity gels tend to release drugs more slowly, making CMC an excellent choice for applications requiring sustained or extended drug release. This property is particularly beneficial in treatments requiring consistent drug levels over extended periods, such as in chronic disease management.

Case Studies of Carboxymethy Cellulose-based Drug Delivery Systems

Several case studies highlight the effectiveness of CMC in drug delivery systems. For instance, in one study, CMC was used to create oral drug delivery systems for diabetes medication. The CMC matrix provided a sustained release of the drug, improving glycemic control in patients by maintaining steady medication levels in the bloodstream.

Another application of CMC in drug delivery is seen in chemotherapy. CMC hydrogels have been used to encapsulate and gradually release chemotherapy drugs, targeting cancer cells while reducing the exposure of healthy cells to the toxic effects of the drugs. This approach has shown promise in reducing side effects and improving the overall effectiveness of cancer treatments.

In these examples, the versatility of carboxymethylcellulose sodium and its derivatives in formulating various drug delivery systems is evident. These case studies not only demonstrate the practical applications of CMC in medicine but also underscore its potential to revolutionize drug delivery methodologies for a wide range of medical conditions.

Use of Carboxymethy Cellulose in Wound Care

Carboxymethy Cellulose in the Development of Wound Dressings

In the field of wound care, Carboxymethy cellulose (CMC) has emerged as a key material in the development of advanced wound dressings. Its hydrophilic nature plays a crucial role here, allowing CMC-based dressings to absorb excess wound exudate while maintaining a moist healing environment. This balance is essential for optimal wound healing, as it prevents the wound bed from drying out, which can slow down the healing process, and also minimizes the risk of maceration.

CMC dressings are known for their soft, gel-like consistency upon contact with wound fluids. This feature not only provides comfort to the patient but also facilitates the natural healing process by providing a protective cushioning over the wound. Moreover, the ease of removal of CMC dressings without causing trauma to the healing tissue is a significant advantage, especially in the treatment of chronic wounds.

Advantages of Carboxymethy Cellulose in Promoting Wound Healing and Tissue Regeneration

The application of carboxymethylcellulose sodium in wound care extends beyond moisture management. CMC has been found to aid in the healing process itself. Its properties can help in reducing inflammation and protecting the wound from external contaminants, thereby lowering the risk of infection.

Additionally, CMC’s biocompatibility makes it an excellent medium for incorporating other therapeutic agents, such as antimicrobials or growth factors, into wound dressings. These combinations can further enhance the healing process, addressing specific needs such as infection control or accelerated tissue regeneration.

In the realm of tissue regeneration, CMC’s role is also significant. Its structure can support the growth and proliferation of skin cells, thereby facilitating the regeneration of damaged tissue. This property is particularly valuable in the treatment of severe burns and other extensive wounds, where rapid and effective tissue regeneration is crucial.

Carboxymethy Cellulose in Medical Implants and Tissue Engineering

Application of Carboxymethy Cellulose in Designing Medical Implants

In the evolving field of biomedical engineering, Carboxymethy cellulose (CMC) has found a significant role in the design and development of medical implants. The biocompatibility of CMC is a key factor in its suitability for implantable devices. It poses minimal risk of immune response or rejection, making it a safe choice for long-term implantation in the body.

CMC’s versatility allows for its use in a variety of implantable devices, ranging from drug-eluting stents to biodegradable scaffolds. In drug-eluting stents, for example, CMC can be used as a coating material to control the release of medication that prevents artery re-blockage post-angioplasty. This application highlights the dual role of CMC as both a structural component and a functional material in medical implants.

Carboxymethy Cellulose’s Role in Tissue Engineering and Regenerative Medicine

In the realm of tissue engineering and regenerative medicine, carboxymethylcellulose sodium plays a pivotal role. CMC serves as an excellent scaffold material, providing a structure upon which cells can grow and regenerate tissue. This is particularly important in the development of artificial skin, organ tissue, and other regenerative therapies.

The hydrophilic nature of CMC also supports the creation of a hydrated environment conducive to cell growth and differentiation. This aspect is crucial for tissue engineering, where the goal is to create functional tissue that can integrate seamlessly with the body’s existing systems.

Additionally, the ability to modify the chemical and physical properties of CMC allows for the creation of scaffolds that mimic the natural extracellular matrix, a critical factor in the success of tissue engineering applications. These modifications can tailor the scaffold to match the specific mechanical and biochemical requirements of the target tissue.

Challenges and Limitations in the Medical Use of Carboxymethy Cellulose

Technical and Biocompatibility Challenges

While Carboxymethy cellulose (CMC) offers numerous advantages in medical applications, there are also challenges and limitations to its use. One significant technical challenge is achieving the optimal degree of substitution and molecular weight, which are crucial for the specific application. These parameters directly affect the properties of CMC, such as viscosity and solubility, and thus must be precisely controlled to meet the demands of different biomedical applications.

Another challenge is ensuring the consistent quality of CMC. Variations in the manufacturing process can lead to inconsistencies in the final product, which can affect its performance in medical applications. Therefore, stringent quality control measures are essential to ensure the reliability and safety of CMC-based products.

Biocompatibility is another critical concern, especially in applications involving direct contact with tissues or blood. While CMC is generally considered biocompatible, its interaction with the body’s immune system can vary depending on its chemical composition and the specific application. Comprehensive biocompatibility testing is necessary to ensure that CMC does not elicit an adverse immune response or cause inflammation.

Regulatory Hurdles and Safety Concerns

Regulatory hurdles are another significant challenge in the medical use of CMC. As with all materials used in medical devices and pharmaceuticals, CMC must undergo rigorous regulatory scrutiny to ensure its safety and efficacy. This process can be lengthy and complex, requiring extensive testing and validation to meet the standards set by regulatory bodies such as the FDA and EMA.

Safety concerns are paramount, particularly regarding the degradation products of CMC and their potential effects on the body. Understanding and controlling the degradation behavior of CMC is essential to ensure that its breakdown products are non-toxic and do not interfere with the body’s normal functions.

Future Directions and Research Opportunities

Emerging Trends and Potential Future Applications of Carboxymethy Cellulose in Biomedicine

The future of Carboxymethyl cellulose (CMC) in biomedicine is marked by exciting possibilities and emerging trends. One of the promising areas is the development of more sophisticated drug delivery systems. Researchers are exploring ways to modify CMC molecules to create targeted delivery mechanisms that can navigate to specific cells or tissues, enhancing the effectiveness and reducing the side effects of treatments.

Another emerging application is in the field of 3D bioprinting. CMC’s properties make it an ideal bio-ink for printing 3D tissue models. These models can be used for drug testing, reducing the need for animal models, and providing more accurate human tissue responses.

Additionally, the integration of CMC with nanotechnology is a growing area of interest. Nanocomposite materials incorporating CMC could lead to breakthroughs in various applications, including advanced wound dressings with enhanced healing properties and implants with improved biocompatibility and functionality.

Areas Needing Further Research and Development

While the potential applications of CMC are vast, further research and development are crucial to overcome current limitations and fully exploit its capabilities. One area requiring more exploration is the long-term biodegradability and bioabsorption of CMC in the body. Understanding and controlling these aspects are essential for safe and effective use in long-term implants and tissue engineering.

Another research focus is the interaction of CMC with different cell types and biological environments. Comprehensive studies are needed to understand these interactions better and optimize CMC for specific biomedical applications, ensuring maximum efficacy and safety.

Lastly, scaling up the production of specialized CMC variants for medical use while maintaining consistency and quality is a challenge that needs addressing. Research into more efficient and sustainable production methods will be key to making advanced CMC applications commercially viable and widely accessible.

In conclusion, Carboxymethy cellulose (CMC) has established itself as an invaluable material in the biomedical field. Its unique properties, such as high water solubility, adjustable viscosity, and biocompatibility, have paved the way for diverse applications ranging from advanced wound care to innovative drug delivery systems. The role of CMC in tissue engineering and medical implants further underscores its significance in advancing medical technologies and improving patient outcomes.

The journey of CMC, from a simple thickening agent to a cornerstone in biomedical applications, reflects the dynamic nature of material science and its intersection with human health. The adaptability and versatility of carboxymethylcellulose sodium and its derivatives in meeting the complex demands of medical science have been a key factor in its widespread adoption and continued exploration.

Looking ahead, the potential of CMC in biomedicine is vast and still unfolding. The ongoing research and development in tailoring its properties for specific medical applications promise to open new frontiers in healthcare. Challenges such as biocompatibility, regulatory hurdles, and production scalability are areas of focus that will shape the future trajectory of CMC’s use in medicine.

In summary, the evolution of CMC in the biomedical sector is a testament to the power of innovative material science in transforming healthcare. As research continues to uncover new applications and refine existing ones, CMC is poised to play an even more significant role in the future of medical science and patient care.