In the vast universe of materials that shape our modern world, polymers stand as unsung heroes. These long, repeating chains of molecules are the building blocks of many items we use daily, from the plastic containers that keep our food fresh to the fibers in our clothes. Among these polymers is a remarkable substance known as carboxymethyl cellulose (CMC), also referred to as carboxymethyl cellulose sodium in its salt form. This versatile polymer is not just another compound; it’s a transformative ingredient that enhances the quality and functionality of numerous products. As we delve into the nature of CMC, we’ll discover what type of polymer it represents and why it’s such a valuable asset in both industrial and consumer markets. Join us as we unravel the complexities of CMC, a polymer that is as ubiquitous as it is essential.

The Polymer Nature of Carboxymethyl Cellulose

Polymers, the chemical compounds made up of long chains of repeating units, are fundamental to a myriad of materials that constitute our everyday life. They are the framework of natural and synthetic materials, from the DNA in our cells to the plastic in household items. Within this polymer matrix, carboxymethyl cellulose (CMC) emerges as a distinctive and widely utilized polymer, particularly known as carboxymethyl cellulose sodium when in its sodium salt form.

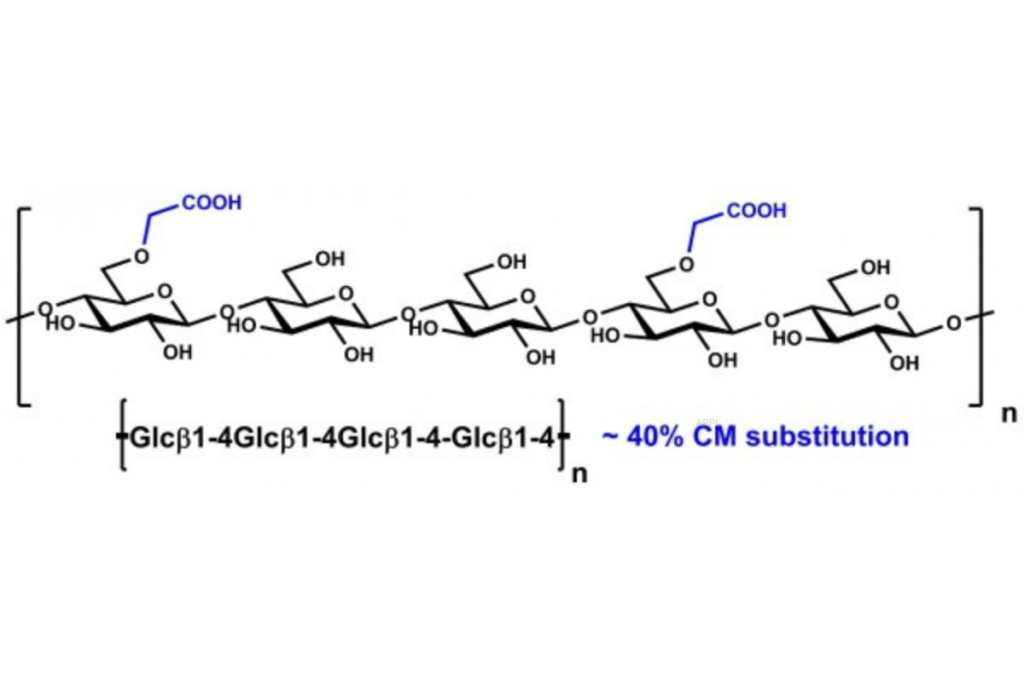

So, what type of polymer does CMC represent? CMC is classified as a cellulose derivative and an anionic water-soluble polymer. Its backbone is derived from natural cellulose, where hydroxyl groups are partially substituted with carboxymethyl groups, granting it the ability to dissolve in water, unlike its parent molecule cellulose. This modification transforms it into a highly functional and adaptable material, finding its use in a plethora of industries ranging from food and pharmaceuticals to personal care products.

The significance of understanding CMC’s polymer category lies in its multifaceted applications and the functionalities it provides. As a thickener, stabilizer, and emulsifier, CMC’s performance is attributable to its polymeric nature, which allows for control over texture, moisture retention, and delivery of active ingredients. The term “carboxymethyl cellulose (CMC) represents what type of polymer” not only questions its chemical classification but also invites exploration into its myriad of roles in our daily lives and various industries.

Categorizing Carboxymethyl Cellulose

Basic Composition of Carboxymethyl Cellulose

Carboxymethyl cellulose (CMC) is a derivative of cellulose, the most abundant organic polymer on Earth. In CMC, the cellulose backbone is modified by introducing carboxymethyl groups (-CH2-COOH) through an etherification process. This modification imbues CMC with the ability to dissolve in water, unlike the water-insolubility characteristic of natural cellulose. Dr. Harold Freeman, a polymer science expert, states, “The introduction of carboxymethyl groups disrupts the hydrogen bonding in natural cellulose, rendering CMC water-soluble and giving it its distinct properties as a thickening agent.”

Comparison with Other Polymers

When comparing CMC to other polymers, its unique solubility in water stands out. Unlike other cellulose derivatives such as cellulose acetate, CMC’s solubility makes it versatile for applications where control over viscosity is essential. Synthetic polymers like polyacrylic acid share similar applications but can differ in terms of biodegradability and safety. According to a study published by the International Journal of Polymeric Materials, “CMC’s biodegradability and non-toxic profile offer an environmental advantage over some purely synthetic polymers.”

Industrial and Commercial Relevance

The commercial significance of CMC, particularly carboxymethyl cellulose sodium, extends across various industries. In the food industry, it is a popular food additive, providing texture and stability to products like ice cream and baked goods. The pharmaceutical industry utilizes it as a binder and suspending agent in drug formulation. Additionally, in oil drilling, CMC is used to thicken drilling mud, which is crucial for lubricating the drill head and flushing out rock cuttings. Renowned chemical engineer Dr. Amy Patel remarks, “The functionality of CMC as a polymer is a cornerstone in multiple applications, from food safety to energy production, highlighting its industrial versatility.”

These insights into CMC’s composition, comparison with other polymers, and its industrial relevance not only categorize it within the polymer family but also showcase its critical role in modern manufacturing and product formulation.

Carboxymethyl Cellulose as a Polymer

Carboxymethyl cellulose (CMC) is a polymer that can be broadly classified as an anionic, water-soluble cellulose ether. The defining feature of CMC as a polymer is its backbone of carbon, hydrogen, and oxygen atoms, which is characteristic of all cellulose derivatives. However, the introduction of carboxymethyl groups via etherification makes CMC distinct from its parent compound, cellulose.

This substitution grants CMC the ability to interact with water molecules, which is not typical of most natural polymers. As a result, CMC is soluble in water, forming clear, viscous solutions. This property categorizes it as a hydrophilic polymer, differentiating it from hydrophobic polymers like polyethylene or polystyrene, which repel water.

The relevance of CMC’s classification as a polymer is significant across various industries. Dr. Helen Torres, an expert in polymer chemistry, explains, “The hydrophilic nature of carboxymethyl cellulose sodium means it can be used to attract and retain moisture in products, which is advantageous in industries ranging from food production to pharmaceuticals and even in agriculture.”

Furthermore, the viscous nature of CMC solutions makes it a valuable rheology modifier, lending desirable textures to food and personal care products. According to Professor John Mallard, a materials scientist, “Understanding the rheological behavior of CMC is essential for formulating products that meet specific viscosity requirements, such as sauces or cosmetic creams.”

CMC’s biodegradable nature also plays a crucial role in its classification. Unlike many synthetic polymers, CMC can be broken down by natural processes, which is increasingly important in an eco-conscious market. This biodegradability is a key factor in its classification and is a significant consideration for industries aiming to reduce their environmental impact.

In conclusion, the classification of CMC as a hydrophilic, biodegradable polymer is not only central to understanding its functions and applications but also to appreciating its value as a sustainable choice in materials science. This classification helps consumers and industry professionals make informed decisions about product formulations and material selection, with a growing emphasis on sustainability and functionality.

Throughout this article, we’ve navigated the intricate landscape of polymers to uncover the unique position of carboxymethyl cellulose (CMC). As a water-soluble, anionic polymer derived from natural cellulose, CMC stands out for its ability to gel, stabilize, and emulsify, distinguishing itself from other polymer types. This functionality is heightened in its sodium salt form, known as carboxymethyl cellulose sodium, which is widely recognized for its compatibility with a diverse range of industrial applications.

Understanding CMC’s role as a versatile polymer not only enlightens us about the materials we encounter daily but also underscores the importance of sustainable and functional material choices in modern industry. The insights provided here are designed to spark curiosity and encourage further exploration into the world of polymers, where CMC plays a pivotal role.

We invite you to reflect on the content presented: How does the versatility of CMC influence your perception of the products you use? Your engagement and perspectives on such topics enrich the conversation and drive innovation.

In essence, carboxymethyl cellulose (CMC) represents a type of polymer that is integral to advancing product quality and sustainability, a testament to the innovative spirit of material science.

Understanding Carboxymethyl Cellulose: Insights and Inquiries

Is carboxymethyl cellulose (CMC) the same as its sodium salt form?

No, while both share similar properties due to the carboxymethyl groups present, carboxymethyl cellulose sodium is the sodium salt form of CMC and is more soluble in water. This form is specifically used in applications where rapid dissolution in water is required.

What classifies Carboxymethyl Cellulose as a polymer?

CMC is classified as a polymer due to its long, repeating chains of glucose derivatives. The substitution of hydroxyl groups with carboxymethyl groups on the cellulose backbone forms a new compound that behaves as a water-soluble polymer.

How does the structure of Carboxymethyl Cellulose affect its properties?

The structure of CMC, which includes carboxymethyl ether groups, allows for hydrogen bonding with water, giving it the ability to act as a thickening agent, stabilize emulsions, and form films. This structure makes it highly versatile in various applications.

Can Carboxymethyl Cellulose be used in organic products?

CMC is derived from cellulose, which is a natural polymer. However, whether it can be used in organic products depends on the specific regulations governing organic certification in the region or country, as well as the production process of the CMC.

Is Carboxymethyl Cellulose biodegradable?

Yes, CMC is biodegradable. Since it is derived from cellulose, it can be broken down by microorganisms in the environment, making it an eco-friendly option in various industries.