Understanding the intricate properties of chemical compounds is crucial in numerous industrial applications. Density, a fundamental property, plays a pivotal role in determining the behavior and functionality of these compounds. Among them, carboxymethyl cellulose (CMC) stands out as a compound widely used across diverse sectors, from food to pharmaceuticals. Its unique property, carboxymethyl cellulose density, significantly influences two critical aspects: viscosity and texture. This article delves into the world of CMC, unraveling how its density shapes its physical characteristics and, consequently, its suitability for various industrial applications.

Carboxymethyl cellulose, a derivative of cellulose, is renowned for its thickening and stabilizing abilities. As industries strive for precision and quality, understanding the relationship between CMC’s density and its resultant physical properties becomes imperative. This exploration is not just about comprehending a scientific fact; it’s about grasping how a seemingly minor property like density can have far-reaching effects on a product’s performance and consumer satisfaction.

In this discussion, we will dissect the concept of density in the realm of chemical compounds, particularly focusing on carboxymethyl cellulose. We will uncover how variations in density influence CMC’s viscosity and texture, and why this understanding is vital for industry professionals. By the end of this journey, the reader will gain a comprehensive insight into carboxymethyl cellulose density and its critical impact on the compound’s application in various industries.

Exploring Carboxymethyl Cellulose: A Brief Overview

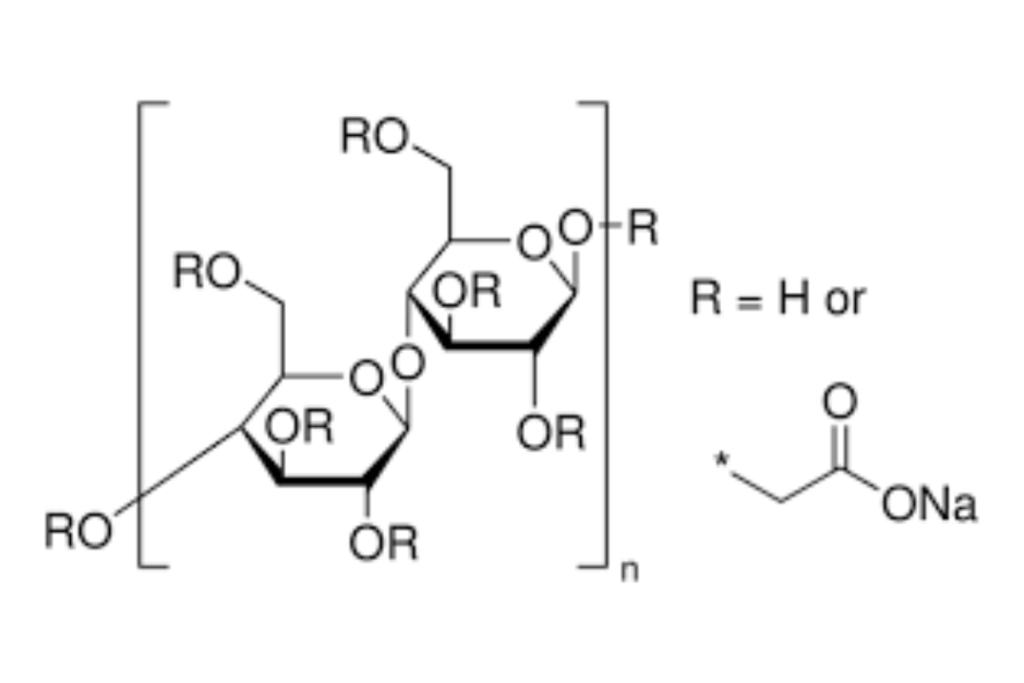

Carboxymethyl cellulose (CMC), a versatile and widely used compound, plays a significant role in various industries due to its unique properties. This white, odorless powder, derived from cellulose, has become a staple in applications ranging from food production to pharmaceuticals. The importance of carboxymethyl cellulose lies not just in its chemical makeup, but in how its properties, such as density, can be manipulated to suit different needs.

Understanding carboxymethyl cellulose involves delving into its general properties. As a water-soluble polymer, CMC has the ability to thicken, stabilize, and retain moisture in products. The versatility of CMC stems from its ability to modify its density, which in turn impacts its efficacy in various applications. For example, a higher density CMC might be preferred in food products where a thicker consistency is desired, while a lower density might be suitable for pharmaceutical applications where a lighter texture is required.

Highlighting the significance of understanding the relationship between CMC’s density and its physical properties is crucial. This knowledge not only aids in selecting the right type of CMC for specific applications but also in achieving the desired quality and functionality of the final product. Thus, a comprehensive grasp of carboxymethyl cellulose, especially its density, is essential for professionals in industries where precise manipulation of compound properties is key to product success.

The Science Behind Carboxymethyl Cellulose Density and Its Effects

Understanding the influence of carboxymethyl cellulose (CMC) density on its physical properties is crucial in various industrial applications. This section delves into the scientific aspects of CMC density, its impact on viscosity, and its influence on texture, all of which are vital for achieving desired product characteristics.

Subsection 1: Understanding Carboxymethyl Cellulose Density

CMC density is a measure of its mass per unit volume and is a critical parameter in determining its physical behavior. The density of CMC is typically calculated using standard laboratory techniques and is influenced by factors like molecular weight and degree of substitution. Scientific studies, particularly in the field of polymer science, provide valuable insights into the determination and implications of CMC density.

Subsection 2: Impact on Viscosity

Viscosity, a measure of a fluid’s resistance to flow, is directly influenced by the density of CMC. Higher density CMC typically exhibits greater viscosity, making it an ideal thickening agent in products like food and cosmetic creams. Material science research has shown that varying the density of CMC can significantly alter the viscosity of a solution, making it a crucial factor in formulation design.

Subsection 3: Influence on Texture

The texture of products containing CMC is also affected by its density. In applications such as gel-based cosmetics or food thickeners, the texture can range from light and airy to thick and substantial, depending on the density of the CMC used. Industrial case studies illustrate how varying CMC density can produce different textures in products, affecting consumer perception and satisfaction.

In conclusion, the density of carboxymethyl cellulose plays a fundamental role in dictating its viscosity and texture. This understanding is key for industries to manipulate CMC properties effectively, ensuring optimal performance in various applications.

Practical Implications in Various Industries

The density of carboxymethyl cellulose (CMC) significantly impacts its practical applications across various industries, from food production to pharmaceuticals and cosmetics. This section explores the real-world implications of controlling CMC density in these sectors, emphasizing its critical role in determining product quality and consumer satisfaction.

Food Industry

In the food sector, the precise adjustment of CMC density is vital for achieving the desired consistency in products like sauces, ice creams, and baked goods. A higher density CMC can create thicker, more stable textures, essential for maintaining the quality of food items during storage and consumption. The food industry often relies on experimental data to determine the optimal CMC density that balances texture and stability.

Pharmaceuticals

In pharmaceuticals, CMC density affects the viscosity and spreadability of topical ointments and gels. A lower density CMC might be used for lighter, more easily absorbed formulations, while a higher density might be preferable for longer-lasting, protective barriers. The pharmaceutical industry adheres to strict standards to ensure that the CMC density aligns with the therapeutic objectives of the product.

Cosmetics

The cosmetic industry utilizes CMC of varying densities to achieve different textures in skincare and makeup products. A lighter, less dense CMC might be favored in lotions for a smooth application, whereas a denser CMC might be used in face masks for a more substantial feel. Cosmetic companies often conduct extensive testing to find the perfect balance of CMC density for consumer appeal and product efficacy.

In summary, the density of sodium carboxymethyl cellulose plays a critical role in various industries. It influences not just the physical properties of products but also their performance, stability, and consumer appeal. Understanding and optimizing CMC density is therefore a key focus area for industry professionals striving to produce high-quality products.

Navigating the Challenges: Optimizing Carboxymethyl Cellulose Density

Optimizing the density of carboxymethyl cellulose (CMC) presents unique challenges across different industries. This section offers insights into these challenges and provides practical guidelines for professionals on manipulating CMC density for achieving desired viscosity and texture.

Addressing Industry-Specific Needs

Each industry has specific requirements for CMC density based on the application. For example, the food industry may require a particular viscosity for sauces, while pharmaceuticals might need a specific texture for ointments. Understanding these unique requirements is crucial for optimizing CMC density.

Balancing Viscosity and Texture

Achieving the right balance between viscosity and texture is a common challenge. A higher density of CMC can increase viscosity but may also result in a texture that is too heavy or sticky for the intended application. Conversely, reducing density to achieve a lighter texture might compromise the stability of the product.

Consistency and Reproducibility

Maintaining consistency in CMC density across batches is vital for product quality. Variations in raw materials or manufacturing conditions can affect density, leading to inconsistent product performance. Implementing strict quality control measures and regular testing can help ensure consistent density.

Environmental Factors

Environmental factors such as temperature and humidity can impact the behavior of CMC, altering its density and, consequently, its effectiveness. Understanding and controlling these factors during both manufacturing and storage is essential.

Technological Advancements

Leveraging technological advancements in manufacturing and testing can aid in better controlling and optimizing CMC density. Advanced analytical techniques can provide more accurate measurements and insights, leading to improved product formulations.

In conclusion, effectively optimizing the density of sodium carboxymethyl cellulose requires a deep understanding of the material’s properties, industry-specific needs, and environmental factors. Through careful analysis and controlled manufacturing processes, professionals can overcome these challenges to create products that meet the desired standards of viscosity and texture.

In conclusion, the density of carboxymethyl cellulose (CMC) plays a pivotal role in determining its viscosity and texture, which are critical factors in various industrial applications. This article has explored the intrinsic relationship between CMC density and its physical properties, emphasizing the importance for industry professionals to understand and manipulate this relationship effectively.

Understanding the density of CMC is not just a scientific endeavor but a practical necessity across industries like food, pharmaceuticals, and cosmetics. The ability to control and optimize CMC density directly impacts product quality, consumer satisfaction, and adherence to industry standards. It’s clear that the precise manipulation of CMC density is essential for achieving desired product characteristics, whether it be the right thickness in a food sauce, the proper spreadability of a pharmaceutical cream, or the ideal consistency of a cosmetic product.

The insights and guidelines provided in this discussion aim to assist professionals in navigating the challenges associated with optimizing CMC density. By understanding the nuanced effects of CMC density on viscosity and texture, professionals can innovate and improve product formulations, ultimately contributing to the advancement and quality assurance in their respective fields.