In the intricate dance of culinary science, food additives play a crucial role in ensuring the taste, texture, and longevity of our favorite treats. Among these, one star performer often goes unnoticed, yet its impact on the food industry is colossal. Welcome to the world of carboxymethyl cellulose gum, a common additive that’s hidden in plain sight within an array of products from ice creams to sauces. Understanding how carboxymethyl cellulose gum is made is a journey through chemistry and innovation, revealing the transformation of natural cellulose into a versatile and valuable food additive. This gum’s journey from plant to pantry exemplifies the marvels of modern food science and the continuous quest for perfection in food manufacturing. Join us as we unravel the creation of this omnipresent ingredient that ensures our culinary experiences are not just delightful, but also consistent and safe.

Unveiling the Process

The manufacturing process of carboxymethyl cellulose gum, also known as sodium carboxymethyl cellulose, is a fascinating alchemy of chemistry and engineering. This process, integral to the production of a wide array of food products, pharmaceuticals, and industrial materials, reflects the ingenuity of modern manufacturing.

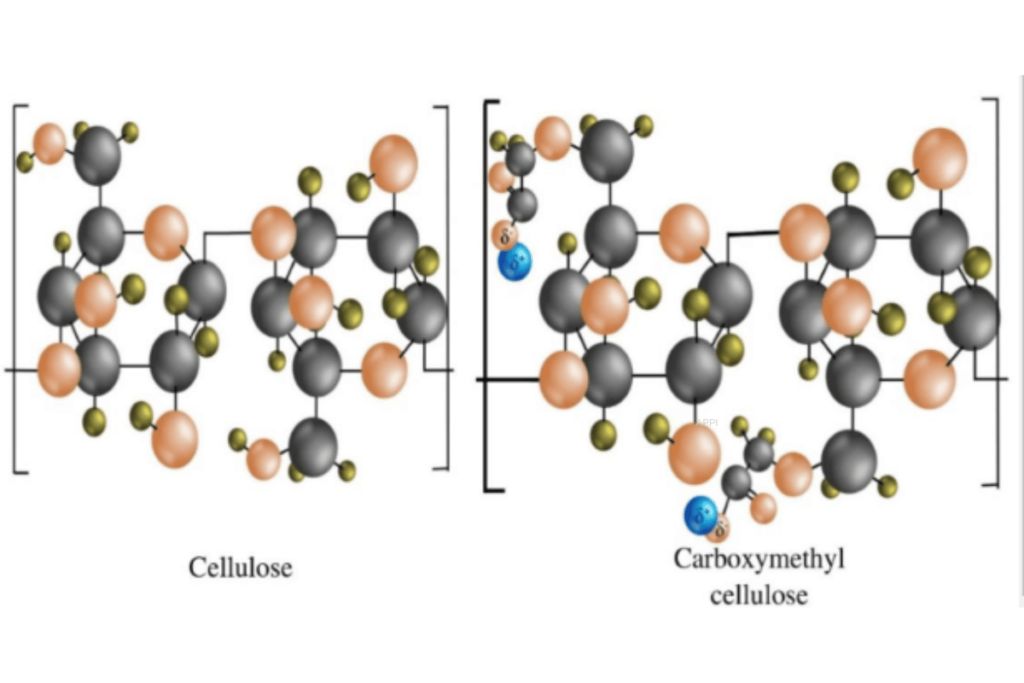

To comprehend how this versatile gum is crafted is to gain insight into the transformation of natural raw materials into a functional additive that meets stringent quality and performance standards. The journey from cellulose to carboxymethyl cellulose gum involves a sophisticated method known as etherification, which alters the structural integrity of cellulose, empowering it with new properties and potentials.

Understanding this process is crucial not only for those in the chemical and manufacturing industries but also for consumers who are increasingly interested in the origins and production methods of the ingredients in their products. It’s a process that underscores the commitment to safety, efficiency, and sustainability in the additive’s production. As we peel back the layers of its creation, we reveal the meticulous steps that ensure carboxymethyl cellulose gum meets the high expectations of its myriad uses.

The Production Journey: From Raw Materials to Gum

Starting Materials

The journey of carboxymethyl cellulose (CMC) gum production begins with cellulose, the structural component of plant cell walls, which is typically derived from wood pulp or cotton lint. The process involves treating the cellulose with sodium hydroxide, which prepares it for the subsequent chemical reaction. As Dr. James O. Jenkins, a seasoned chemist in polymer production, notes, “The choice of cellulose source can impact the final properties of CMC, with wood pulp often leading to a higher purity and more uniform product.”

The Chemical Reaction

The core of CMC gum production is the etherification process, where cellulose reacts with chloroacetic acid in the presence of sodium hydroxide, resulting in the substitution of hydroxyl groups with carboxymethyl groups. This reaction typically occurs under controlled conditions, including temperature and pH monitoring, to ensure consistent quality. “The etherification process is crucial as it determines the degree of substitution of the cellulose molecule, which in turn affects the solubility and viscosity of the final product,” explains Dr. Helen Grant, an expert in cellulose derivatives.

Purification and Finishing

Once etherification is complete, the crude CMC gum undergoes several purification steps. These may include neutralization, washing, and drying to remove any unreacted chemicals and by-products. The purified CMC is then ground to a fine powder, which can be further processed into various grades suitable for different applications. “Purification is not just a matter of removing impurities, but also fine-tuning the physical and chemical properties of the CMC gum to meet specific industry needs,” states Mr. Albert F. Kent, an industrial engineer specializing in polymer processing.

The meticulous process of transforming basic plant materials into a functional food additive underscores the innovation within the food science and manufacturing sectors. Each step, from selecting the raw materials to the final purification, reflects the precision and care that goes into producing a consistent and high-quality product that meets the rigorous standards of various industries.

Insights into the Manufacturing of Carboxymethyl Cellulose Gum

The production of carboxymethyl cellulose (CMC) gum, particularly sodium carboxymethyl cellulose, is a complex synthesis process that requires careful selection of raw materials and precise control of reaction conditions. Manufacturers are continually refining this process to meet the diverse needs of various industries, from food to pharmaceuticals.

Choices in Raw Materials and Reagents

The primary raw material for CMC gum is high-purity cellulose, which can be sourced from wood pulp or cotton lint. The type of cellulose chosen can affect the properties of the final product, such as its viscosity and solubility. Dr. Anne-Marie Kelterer, a prominent chemical engineer, notes, “The selection of cellulose is a delicate balance between cost-effectiveness and the desired molecular weight of the CMC, which will determine its application.”

The chemicals used in the etherification process are also chosen for their reactivity and the quality of the CMC they produce. Sodium hydroxide and chloroacetic acid are the primary reagents involved in the reaction. The purity of these chemicals is paramount, as impurities can lead to variations in the CMC’s performance.

Solutions to Production Challenges

One of the main challenges in the production of CMC gum is controlling the degree of substitution (DS), which determines the number of hydroxyl groups on the cellulose molecule that have been replaced with carboxymethyl groups. This DS affects the gum’s solubility and its behavior in solutions. Manufacturers use advanced monitoring techniques to ensure that the DS remains consistent across batches. “The DS is what makes CMC so versatile; however, achieving and maintaining the correct DS is one of the most critical aspects of the production process,” states Dr. Kelterer.

Another challenge is the potential for unwanted by-products, which can affect the purity of the CMC gum. To address this, manufacturers have developed purification processes that may include filtration, alcohol precipitation, and drying methods to ensure the CMC gum meets food-grade or pharmaceutical-grade standards.

Improving the Manufacturing Process

Continuous improvement is key in the manufacturing of CMC gum. Manufacturers invest in research and development to find more efficient and environmentally friendly methods of production. The use of green chemistry principles, such as reducing waste and energy consumption, is becoming increasingly important. As the industry progresses, manufacturers are also exploring the use of alternative, sustainable sources of cellulose to reduce the environmental impact of production.

The process of creating carboxymethyl cellulose gum is an ongoing journey of innovation. It involves not only a deep understanding of chemistry and engineering but also a commitment to sustainability and quality. The insights provided by experts in the field emphasize the sophisticated nature of this production process and the solutions developed to overcome its inherent challenges.

In delving into the intricate production of carboxymethyl cellulose gum, we’ve traced the path from natural cellulose fibers to the versatile and widely used compound known as sodium carboxymethyl cellulose. This journey from plant-based materials to a multifunctional food additive is a testament to the ingenuity of modern chemical processing.

The process, marked by the critical etherification reaction and meticulous purification stages, reveals the complexity behind a substance often taken for granted. It is the intersection of precise science and practical application, resulting in a product that enhances the quality of numerous goods.

As we conclude this exploration, it’s clear that the production of carboxymethyl cellulose gum is a blend of art and science, requiring expertise and attention to detail to ensure the final product meets the high standards expected by industries and consumers alike. Whether you are a stakeholder in the manufacturing world or a curious consumer, the story of how this gum is made reflects the remarkable efforts behind everyday products.

In just a sentence or two: The creation of carboxymethyl cellulose gum is a sophisticated alchemy, transforming simple plant material into an indispensable additive that plays a silent yet significant role in our daily lives.

Understanding Carboxymethyl Cellulose Gum: Your Questions Answered

What is the main raw material used to make carboxymethyl cellulose (CMC) gum?

The primary raw material for producing CMC gum is pure cellulose, which is typically derived from wood pulp or cotton fibers. This cellulose undergoes a chemical transformation to become the water-soluble sodium carboxymethyl cellulose used in numerous applications.

Can you explain the chemical reaction that creates carboxymethyl cellulose gum?

CMC gum is produced through a process called etherification. This involves reacting cellulose with chloroacetic acid and sodium hydroxide, causing the cellulose to be substituted with carboxymethyl groups, thus creating the water-soluble gum.

What makes sodium carboxymethyl cellulose different from other thickeners?

Sodium carboxymethyl cellulose is unique due to its high solubility in water and its ability to create non-tacky solutions at varying concentrations, making it a versatile option compared to other thickeners which may not offer the same range of viscosity or texture.

How is the purity of carboxymethyl cellulose gum ensured during manufacturing?

After CMC gum is synthesized, it goes through several purification steps, such as neutralization, alcohol precipitation, and filtration, to remove any by-products or unreacted materials. This ensures that the CMC gum is of the highest quality and meets industry standards for use in products.