The role of Safety Data Sheets (SDS) in industrial settings is vital for ensuring workplace safety and compliance with regulatory standards. These documents are central to the safe handling, storage, and disposal of chemicals, providing critical information to all levels of personnel within an industry. Among such chemicals, Carboxymethyl Cellulose (CMC), a widely used substance in various industrial applications, necessitates a comprehensive understanding of its SDS for safe and compliant usage.

The significance of the Carboxymethyl Cellulose SDS cannot be overstated. This document serves as a cornerstone for industrial safety and environmental protection. It not only instructs on safe handling and potential hazards but also ensures that industries adhere to legal and safety norms, thereby safeguarding workers and the environment. The SDS for CMC, identified by its chemical abstracts service (CAS) number 9004-32-4, is an essential tool for industrial professionals, providing them with the necessary information to handle this chemical responsibly and in compliance with regulatory requirements.

In essence, the Carboxymethyl Cellulose SDS is a critical resource that empowers industries to manage the risks associated with the use of this compound. Understanding and adhering to the guidelines and information provided in the SDS is imperative for maintaining a safe industrial environment and for upholding industry-wide safety standards.

Understanding Carboxymethyl Cellulose and Its SDS

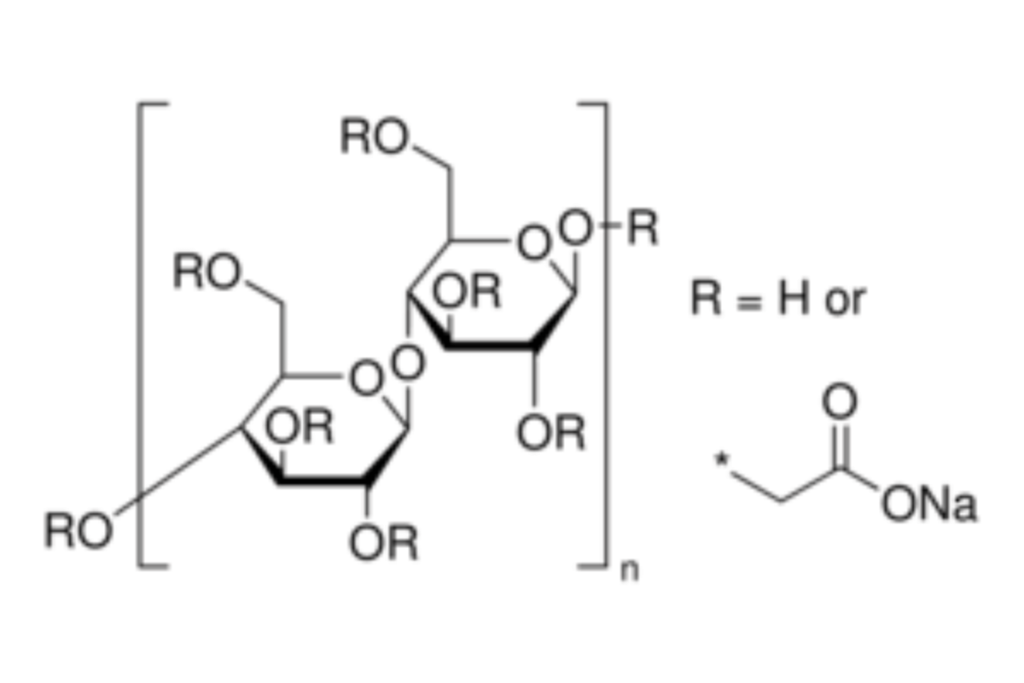

Carboxymethyl Cellulose (CMC), a versatile chemical compound, plays a pivotal role in various industrial sectors. Known for its unique properties, such as high viscosity and non-toxic nature, CMC is extensively utilized in industries like food processing, pharmaceuticals, and paper manufacturing. It’s vital for professionals in these fields to have a deep understanding of CMC, not only for its application but also for ensuring safety and compliance.

The Safety Data Sheet (SDS) of Sodium Carboxymethyl Cellulose serves as a critical document, providing comprehensive information about this compound. The SDS is designed to inform users about the proper handling procedures, potential hazards, and emergency measures related to CMC. It’s a key element in maintaining industry safety standards, acting as a guide for safe practice in handling, storage, and disposal of CMC.

Understanding the SDS of CMC is essential for industry professionals. This document, adhering to the Material Safety Data Sheet (MSDS) standards, details the chemical’s physical and chemical properties, including CAS 9004-32-4, which is the unique identifier for CMC. The SDS also contains crucial information on first-aid measures, fire-fighting techniques, accidental release measures, and handling and storage guidelines, which are indispensable for ensuring safety in industrial environments where CMC is used.

In summary, the SDS of Carboxymethyl Cellulose is not just a regulatory requirement; it’s a fundamental component of industrial safety and compliance. Understanding and adhering to the information provided in the SDS is paramount for the safe and effective use of CMC in various industrial applications.

Key Components of the Carboxymethyl Cellulose SDS

The Safety Data Sheet (SDS) for Carboxymethyl Cellulose (CMC) is an essential document for industrial safety and compliance. It comprises several key components that provide detailed information about the handling, storage, and potential hazards of CMC. Understanding these components is crucial for industry professionals to ensure a safe working environment.

Subsection 1: Composition and Information

The SDS of CMC offers in-depth details about its chemical composition. It outlines the substance’s primary components, including the CAS number 9004-32-4 for Carboxymethyl Cellulose, and any additives or impurities that might be present. This section is critical for understanding the chemical nature of CMC and preparing for its safe handling in industrial processes.

Subsection 2: Handling and Safety Measures

This part of the SDS provides comprehensive guidelines on how to safely handle CMC. It includes recommendations on protective equipment, such as gloves and goggles, and instructions for safe storage to prevent accidental exposure or contamination. These guidelines are instrumental in minimizing risks associated with CMC handling and ensuring the safety of personnel.

Subsection 3: Health and Environmental Hazards

The SDS meticulously details the health risks and environmental hazards associated with CMC. It covers potential health effects, including any known acute or chronic risks upon exposure. The document also sheds light on the environmental impact of CMC, guiding industries in implementing measures to mitigate any negative effects on the environment.

Overall, the key components of the CMC SDS provide a thorough understanding of the substance’s properties, handling guidelines, and associated risks. This information is crucial for industries to maintain compliance with safety regulations and ensure a secure workplace environment while handling Carboxymethyl Cellulose.

SDS and Industrial Compliance: The Case of Carboxymethyl Cellulose

The Safety Data Sheet (SDS) for Carboxymethyl Cellulose (CMC) plays a pivotal role in ensuring industrial compliance and maintaining workplace safety. This document is not just a mere formality; it’s a crucial tool that aids industries in adhering to rigorous safety standards and regulations.

Importance in Regulatory Compliance

The CMC SDS serves as a comprehensive guide that aligns with regulatory requirements set by health and safety authorities. It provides the necessary data to comply with legal obligations, ensuring that industries meet the standards for safe handling, storage, and disposal of CMC. This compliance is vital for avoiding legal repercussions and maintaining a company’s reputation for safety.

Ensuring Workplace Safety

One of the primary roles of the CMC SDS is to secure the safety of workers handling this compound. It educates employees about the potential hazards, equipping them with knowledge on how to safely manage CMC. This includes understanding exposure limits, appropriate personal protective equipment (PPE), and emergency response actions in case of accidents.

Environmental Protection

Besides safeguarding human health, the SDS also underscores the environmental implications of using CMC. It details measures to prevent environmental contamination, ensuring that industries take responsible steps to minimize their ecological footprint while using CMC in their processes.

Streamlining Safety Protocols

For industries, the SDS acts as a central reference point to develop comprehensive safety protocols around the use of CMC. It aids in training programs, risk assessments, and the formulation of internal safety standards, creating a culture of safety and awareness within the organization.

In conclusion, the Carboxymethyl Cellulose SDS is an indispensable resource for industries, serving multiple roles from regulatory compliance to environmental stewardship. It ensures that industries not only abide by legal standards but also uphold the highest levels of safety and responsibility in their operations involving CMC.

Navigating SDS Challenges: Tips for Industry Professionals

The Safety Data Sheet (SDS) for Carboxymethyl Cellulose (CMC) is a crucial document in industrial settings, but interpreting and implementing its guidelines can present challenges. For industry professionals, effectively navigating these challenges is key to ensuring compliance and safety. Here are some practical tips:

Effective Use of SDS Information

- Thorough Review: Regularly review the CMC SDS to stay updated on any changes or new information. This ensures that safety protocols remain current and effective.

- Training and Education: Conduct comprehensive training sessions for all employees handling CMC. Ensure that they understand the SDS contents, particularly the sections on handling, storage, and emergency procedures.

- Accessibility: Keep the SDS readily accessible in the workplace. Digital copies should be easily available to all employees, and physical copies should be placed near storage and handling areas.

Interpreting SDS for Compliance

- Consult Experts: When in doubt, consult safety experts or chemists to clarify complex information within the SDS. Their expertise can provide valuable insights into the practical application of SDS guidelines.

- Cross-Reference with Regulations: Align the SDS information with local and national safety regulations. This helps in understanding how the SDS supports compliance with broader legal requirements.

- Documentation: Maintain clear records of how SDS guidelines are implemented in daily operations. This documentation is crucial for audits and regulatory inspections.

Addressing Common Challenges

- Language Barriers: If language barriers exist within the workforce, provide translations of the SDS to ensure understanding among all employees.

- Complex Terminology: Break down complex scientific terms into simpler language during training sessions. Use practical examples to illustrate how SDS guidelines apply in real-world scenarios.

- Continuous Updates: Stay informed about updates in safety regulations and how they might affect the interpretation of the SDS. Adapt safety protocols as necessary.

In summary, effectively navigating the challenges associated with the CMC SDS requires a proactive approach, continuous education, and adherence to safety regulations. By implementing these tips, industry professionals can ensure that they not only comply with the necessary standards but also foster a safe and informed workplace environment.

In summarizing the importance of the Safety Data Sheet (SDS) for Carboxymethyl Cellulose (CMC), it is clear that this document is more than just a regulatory requirement; it’s a vital part of ensuring safety and compliance in industrial settings. Here are the key takeaways:

- Compliance and Legal Adherence: The CMC SDS is essential for meeting the stringent regulatory requirements governing industrial safety. It helps industries avoid legal issues and maintain high safety standards.

- Workplace Safety: By detailing critical information on handling, storage, and emergency procedures, the SDS plays a crucial role in protecting employees from potential hazards associated with CMC.

- Environmental Responsibility: The SDS provides necessary guidelines for environmentally safe practices, ensuring industries mitigate their impact on the environment while using CMC.

- Educational Tool: The SDS serves as an educational resource, equipping workers with essential knowledge and fostering a culture of safety and awareness.

- Foundation for Safety Protocols: The SDS is a cornerstone document in developing robust safety protocols, risk assessments, and training programs, thereby enhancing overall workplace safety.

In conclusion, the Carboxymethyl Cellulose SDS is pivotal in navigating the complexities of industrial safety and compliance. Its comprehensive guidelines serve not only to fulfill legal obligations but also to safeguard health, ensure environmental protection, and educate workers, ultimately contributing to the creation of a safer and more responsible industrial environment.