Carboxymethylcellulose Sodium Salt (CMC-Na), also commonly known as sodium carboxymethyl cellulose, is a water-soluble polymer derived from cellulose, the most abundant organic compound on Earth. This compound, distinguished by its unique sodium carboxymethyl cellulose uses, represents a significant advancement in pharmaceutical and industrial applications due to its non-toxic, biodegradable, and versatile nature.

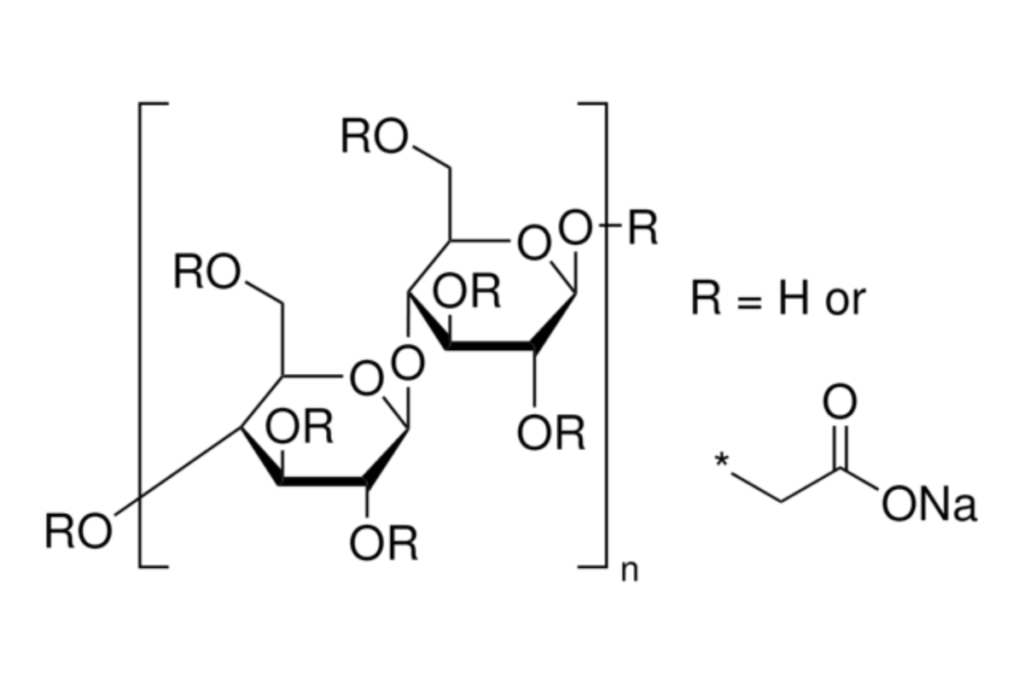

The chemical structure of carboxymethylcellulose sodium molecular weight varies, giving it a wide range of viscosities and properties that are invaluable in various applications. It is produced by the reaction of cellulose with chloroacetic acid in the presence of sodium hydroxide, leading to the introduction of carboxymethyl groups into the cellulose chain.

The historical context of CMC-Na dates back to its initial synthesis and use in the mid-20th century. Initially employed in the food and textile industries, its unique properties quickly garnered interest in the pharmaceutical sector. This shift was mainly due to its remarkable ability to act as a thickener, stabilizer, and emulsifier.

One of the pivotal moments in the evolution of carboxymethylcellulose sodium salt in pharmaceutical applications was the realization of its role in improving the texture and consistency of drug formulations, enhancing the shelf life and ease of administration of various pharmaceuticals. It also played a crucial role in the development of carboxymethyl cellulose sodium eye drops and other specialized medical formulations.

As its uses expanded, carboxymethylcellulose CAS No. and its regulatory status became crucial for quality control in pharmaceutical manufacturing. Moreover, the understanding of its carboxymethylcellulose sodium chemical formula allowed for greater control over its properties and applications in drug formulation.

Today, CMC-Na is extensively used in a variety of pharmaceutical products, ranging from sodium carboxymethyl cellulose in food as a dietary supplement to more complex applications such as in carboxymethylcellulose sodium eye drops uses. Its role in enhancing drug efficacy, improving patient compliance, and ensuring the stability of active pharmaceutical ingredients has been well recognized in the industry.

In conclusion, Carboxymethylcellulose Sodium Salt represents a cornerstone in pharmaceutical formulations. Its continued development and application in the field highlight its versatility and potential in addressing diverse pharmaceutical needs. As we delve further into the unique properties and roles of CMC-Na in pharmaceutical formulations, its significance in advancing drug delivery technologies becomes ever more apparent.

Unique Properties of Carboxymethylcellulose Sodium Salt in Pharmaceutical Formulations

Carboxymethylcellulose Sodium Salt (CMC-Na) stands out in the pharmaceutical industry due to its unique physical and chemical characteristics. These properties make CMC-Na an exceptional choice over other pharmaceutical excipients for a variety of applications.

Key Physical and Chemical Characteristics of Carboxymethylcellulose Sodium Salt

One of the most notable properties of CMC-Na is its high viscosity, which can be adjusted depending on the degree of substitution and the carboxymethylcellulose sodium molecular weight. This variable viscosity allows for precise control over the texture and flow of pharmaceutical formulations, making it ideal for suspensions and gels.

Another significant characteristic of CMC-Na is its excellent water solubility. Unlike other cellulose derivatives, CMC-Na dissolves readily in water, making it an invaluable ingredient in aqueous formulations. This property is particularly important for creating uniform and stable suspensions, which are crucial for the efficacy and shelf life of many pharmaceutical products.

The carboxymethylcellulose sodium chemical formula also endows it with remarkable stability. CMC-Na is resistant to microbial growth and degradation, ensuring the longevity and integrity of pharmaceutical products during storage. Additionally, it has a neutral pH, which is crucial for maintaining the stability of sensitive active ingredients.

Advantages of Carboxymethylcellulose Sodium Salt over Other Pharmaceutical Excipients

One of the key advantages of CMC-Na is its non-toxic and hypoallergenic nature. This makes it suitable for use in a wide range of pharmaceutical formulations, including those for pediatric and geriatric patients. Its safety profile is further supported by its status in the carboxymethylcellulose CAS No. list, indicating regulatory approval for medical use.

CMC-Na also enhances the bioavailability of certain drugs. Its gel-forming ability can slow down the release of active ingredients, providing a sustained release effect. This property is particularly beneficial in formulations where a prolonged therapeutic effect is desired, reducing the frequency of dosing and improving patient compliance.

In addition, CMC-Na serves as a protective colloid, which can prevent the crystallization of active ingredients in solutions and suspensions. This characteristic is crucial for maintaining the efficacy and consistency of dosage forms.

The use of CMC-Na in various pharmaceutical formulations, such as sodium carboxymethyl cellulose in food supplements and carboxymethyl cellulose sodium eye drops, highlights its versatility and functionality as a pharmaceutical excipient. Its unique properties offer numerous advantages over other materials, making it a preferred choice in the development of safe, effective, and patient-friendly pharmaceutical products.

Role of Carboxymethylcellulose Sodium Salt in Drug Delivery Systems

The application of Carboxymethylcellulose Sodium Salt (CMC-Na) in drug delivery systems is a testament to its versatility and efficacy in pharmaceutical formulations. Its unique properties facilitate controlled and sustained release of drugs, making it an indispensable component in modern pharmacotherapy.

Use of Carboxymethylcellulose Sodium Salt in Controlled and Sustained Drug Release

One of the key roles of CMC-Na in drug delivery systems is its ability to modulate the release of active pharmaceutical ingredients. The high viscosity and gel-forming capabilities of CMC-Na make it an ideal medium for controlled drug release. By forming a matrix around the drug, CMC-Na can slow down the rate at which the drug is released into the body. This controlled release is beneficial for maintaining steady drug levels in the bloodstream, reducing the frequency of dosing, and enhancing patient compliance.

In addition to controlling drug release, CMC-Na also contributes to the stability of formulations. Its chemical structure, particularly its carboxymethylcellulose sodium molecular weight, allows it to form stable gels that can encapsulate drugs, protecting them from degradation and ensuring their efficacy over a prolonged period.

Examples of Drug Formulations Utilizing Carboxymethylcellulose Sodium Salt

Various drug formulations capitalize on the benefits of CMC-Na. For instance, in the case of carboxymethyl cellulose sodium eye drops, CMC-Na acts as a lubricant and stabilizer, providing sustained relief for dry eye conditions while ensuring the stability of the active ingredients.

Another example is in oral drug formulations, where CMC-Na is used to control the release of medication for gastrointestinal treatments. Its ability to swell and form a gel in the presence of gastric fluids makes it an excellent carrier for drugs that require gradual absorption in the digestive tract.

CMC-Na is also used in topical formulations, where its soothing and protective properties are harnessed in creams and ointments. In these applications, CMC-Na not only delivers the active ingredients to the targeted area but also provides a moisturizing effect, enhancing the overall therapeutic experience.

The use of Carboxymethylcellulose Sodium Salt in these diverse drug delivery systems highlights its crucial role in enhancing the effectiveness and patient-friendliness of pharmaceutical products. Its ability to provide controlled and sustained release of drugs, coupled with its stabilizing and protective properties, makes CMC-Na an invaluable asset in the realm of drug formulation.

Carboxymethylcellulose Sodium Salt in Oral and Topical Pharmaceutical Formulations

The versatility of Carboxymethylcellulose Sodium Salt (CMC-Na) extends to its application in both oral and topical pharmaceutical formulations. Its unique properties significantly enhance the effectiveness and user experience of these medications.

Application in Oral Tablets, Suspensions, and Topical Creams

In oral drug formulations, such as tablets and suspensions, CMC-Na serves multiple functions. It acts as a binder in tablet formulations, contributing to the tablet’s structural integrity and ensuring uniform distribution of the active ingredient throughout the tablet. This uniformity is crucial for dose accuracy and drug efficacy.

For liquid suspensions, CMC-Na’s role is indispensable. Its thickening and stabilizing properties prevent the active ingredients from settling, ensuring consistent dosing with each administration. Moreover, the viscosity imparted by CMC-Na can improve the palatability of oral medications, making them more acceptable, especially for pediatric and geriatric patients.

In topical formulations like creams and ointments, CMC-Na enhances the product’s texture and spreadability, making it easier to apply. Its moisturizing effect, owing to its hygroscopic nature, also adds to the therapeutic benefits, particularly in skin care and wound healing applications.

Enhancing Drug Stability and Patient Compliance with Carboxymethylcellulose Sodium Salt

The stability of pharmaceutical formulations is a critical aspect of drug development, and CMC-Na plays a vital role in this regard. In both oral and topical formulations, CMC-Na helps in maintaining the stability of the active ingredients, protecting them from degradation due to environmental factors like humidity and temperature.

Additionally, CMC-Na’s ability to control the release of drugs enhances patient compliance. In oral formulations, it can extend the release of medication, reducing the need for frequent dosing. This sustained release not only improves the therapeutic outcome but also makes it more convenient for patients to adhere to their medication schedules.

For topical applications, the soothing effect of CMC-Na, along with its ability to form a protective barrier, can enhance the healing process and provide immediate relief, encouraging continued use as prescribed.

The use of Carboxymethylcellulose Sodium Salt in these diverse pharmaceutical formulations underscores its importance in improving drug efficacy, stability, and patient compliance. Its multifunctional nature makes it a highly valued ingredient in the pharmaceutical industry, catering to the needs of a broad spectrum of medications.

Innovations in Carboxymethylcellulose Sodium Salt for Targeted Drug Delivery

The use of Carboxymethylcellulose Sodium Salt (CMC-Na) in pharmaceuticals has seen significant innovations, particularly in the area of targeted and responsive drug delivery systems. These advancements represent a major leap forward in the field of pharmacotherapy, offering more precise and effective treatment options.

Recent Advancements in Targeted and Responsive Drug Delivery Systems

CMC-Na has become a key player in the development of targeted drug delivery systems. Its ability to be chemically modified allows for the creation of smart drug delivery vehicles. These systems can respond to specific stimuli within the body, such as pH changes, temperature shifts, or the presence of certain enzymes, to release their active ingredients precisely where and when needed.

This targeted approach minimizes the systemic exposure of the body to drugs, thereby reducing potential side effects and increasing the efficacy of treatments. For instance, in cancer therapy, CMC-Na-based drug delivery systems can be designed to release chemotherapeutic agents specifically at the tumor site, maximizing the impact on cancer cells while sparing healthy tissues.

Case Studies Demonstrating Innovative Uses of Carboxymethylcellulose Sodium Salt

One notable case study involves the use of CMC-Na in creating pH-sensitive drug delivery systems for treating gastrointestinal disorders. These systems remain stable in the acidic environment of the stomach but release their active ingredients upon reaching the more alkaline environment of the intestines.

Another example is the use of CMC-Na in ocular drug delivery. Researchers have developed CMC-Na-based eye drops that respond to the pH of the tear film, allowing for a prolonged retention time and sustained drug release, which is particularly beneficial in treating chronic eye conditions.

These innovations in drug delivery utilizing Carboxymethylcellulose Sodium Salt are just the beginning. Ongoing research is exploring the use of CMC-Na in various other responsive systems, including thermosensitive gels for localized drug delivery and implantable devices for long-term medication release.

The advancements in CMC-Na-based targeted and responsive drug delivery systems highlight its potential to revolutionize treatment paradigms across various medical conditions. These developments not only enhance the effectiveness of therapies but also significantly improve patient outcomes and quality of life.

Addressing Challenges and Enhancing Biocompatibility

The integration of Carboxymethylcellulose Sodium Salt (CMC-Na) in pharmaceutical formulations, while beneficial, presents certain challenges. Addressing these challenges is crucial for enhancing the biocompatibility and overall effectiveness of CMC-Na-based drug delivery systems.

Overcoming Solubility and Stability Challenges in Pharmaceutical Formulations

One of the primary challenges with CMC-Na in pharmaceutical formulations is optimizing its solubility and stability. While CMC-Na is generally water-soluble, achieving the right solubility profile for specific applications requires precise control over its molecular weight and degree of substitution. These factors influence the viscosity and texture of the final product, which are critical for the drug’s performance and patient acceptance.

Stability is another crucial aspect, particularly in formulations where CMC-Na interacts with other ingredients. The stability of CMC-Na-based formulations can be affected by factors like pH, ionic strength, and the presence of other excipients. Ensuring stability over the product’s shelf life requires thorough formulation testing and optimization.

Enhancing Biocompatibility and Reducing Adverse Reactions

Enhancing the biocompatibility of CMC-Na is another significant area of focus. While CMC-Na is generally considered safe and non-toxic, ensuring its compatibility with biological systems, especially for long-term or internal applications, is essential. This involves evaluating the immune response and potential for irritation or allergic reactions.

Advancements in the modification of CMC-Na have been instrumental in improving its biocompatibility. Chemical modifications can reduce the potential for adverse reactions and enhance its compatibility with cells and tissues. For instance, modifying the surface properties of CMC-Na can make it more conducive to cell attachment and growth, an important consideration in tissue engineering applications.

In addition, regulatory compliance, as indicated by the carboxymethylcellulose CAS No., plays a crucial role in ensuring the safety and biocompatibility of CMC-Na. Adhering to regulatory standards and conducting comprehensive biocompatibility assessments are essential steps in the development of safe and effective pharmaceutical products.

Addressing these challenges is key to maximizing the therapeutic potential of CMC-Na in pharmaceutical applications. Through ongoing research and development, the optimization of CMC-Na’s properties and its formulation processes continues to enhance its role in creating more effective and biocompatible drug delivery systems.

Regulatory Considerations and Compliance

The use of Carboxymethylcellulose Sodium Salt (CMC-Na) in pharmaceuticals is not just about harnessing its beneficial properties; it also involves navigating a complex landscape of regulatory considerations and compliance standards. Adherence to these regulations is essential for ensuring the safety, quality, and efficacy of pharmaceutical products containing CMC-Na.

FDA and Global Regulatory Standards for Using Carboxymethylcellulose Sodium Salt in Pharmaceuticals

In the United States, the Food and Drug Administration (FDA) sets forth specific guidelines for the use of excipients like CMC-Na in pharmaceutical formulations. These guidelines encompass various aspects, including the purity, quality, and concentration of CMC-Na. The carboxymethylcellulose CAS No. and its chemical identity play a significant role in regulatory filings and approvals.

Globally, regulatory bodies in Europe, Asia, and other regions have their own sets of standards and guidelines for the use of CMC-Na in pharmaceuticals. These standards ensure that CMC-Na used in drug formulations meets international safety and quality benchmarks.

Ensuring Quality Control and Safety in Manufacturing Processes

Quality control is a critical component in the manufacturing process of pharmaceuticals containing CMC-Na. Manufacturers must implement rigorous testing protocols to ensure that CMC-Na meets the required standards for pharmaceutical use. This includes testing for impurities, consistency in molecular weight, and adherence to the specified carboxymethylcellulose sodium chemical formula.

Safety in the manufacturing process is equally crucial. Manufacturers must ensure that the handling and processing of CMC-Na do not introduce contaminants or compromise its quality. This involves maintaining clean and controlled manufacturing environments and adhering to Good Manufacturing Practices (GMP).

Regulatory compliance also extends to the labeling and documentation of pharmaceutical products containing CMC-Na. Accurate labeling ensures that healthcare professionals and patients are informed about the composition and concentration of CMC-Na in the medication, allowing for informed usage and avoidance of potential adverse reactions.

In conclusion, navigating the regulatory landscape and ensuring compliance are fundamental to the successful incorporation of CMC-Na in pharmaceutical formulations. Meeting these stringent standards is key to maintaining the trust and safety of healthcare providers and patients while harnessing the full potential of CMC-Na in medical applications.

Future Prospects and Research Directions

The exploration of Carboxymethylcellulose Sodium Salt (CMC-Na) in pharmaceutical applications is an ever-evolving field, brimming with potential for future advancements. As the demands and complexities of drug formulations increase, so do the opportunities for innovative applications of CMC-Na.

Emerging Trends and Potential Future Applications of Carboxymethylcellulose Sodium Salt in Pharma

One of the most exciting prospects for CMC-Na lies in its potential role in nanomedicine. Researchers are investigating the use of CMC-Na as a carrier for nanoparticles, which could revolutionize targeted drug delivery and diagnostic methods. These nano-scale drug delivery systems could offer unprecedented precision in treating a wide range of diseases, from cancer to chronic inflammatory disorders.

Another emerging trend is the use of CMC-Na in the development of biodegradable polymers for pharmaceutical applications. This approach aligns with the growing emphasis on sustainability in the pharmaceutical industry, offering a more environmentally friendly alternative to traditional polymers.

Furthermore, the integration of CMC-Na with advanced technologies like 3D printing is opening new avenues in drug formulation and personalized medicine. 3D-printed drug delivery systems using CMC-Na could be customized to individual patient needs, optimizing therapeutic outcomes.

Ongoing Research and Development in the Field

Ongoing research is focused on enhancing the physicochemical properties of CMC-Na to improve its functionality in drug formulations. This includes modifying the carboxymethylcellulose sodium molecular weight and degree of substitution to achieve desired solubility, viscosity, and bioadhesion properties.

Researchers are also exploring the synergistic effects of combining CMC-Na with other biopolymers and active ingredients. These combinations could lead to novel formulations with enhanced therapeutic efficacy, stability, and patient compliance.

Studies on the long-term biocompatibility and bioabsorption of CMC-Na are crucial, particularly for its applications in sustained and controlled release formulations. Understanding and mitigating any potential adverse effects will be key to expanding its use in more sensitive medical applications.

The future of CMC-Na in pharmaceuticals is marked by a commitment to innovation and a deeper understanding of its interactions within biological systems. As research progresses, CMC-Na is poised to play an increasingly significant role in the advancement of drug formulation technologies, ultimately leading to better patient outcomes and more efficient treatments.

In summarizing the pivotal role of Carboxymethylcellulose Sodium Salt (CMC-Na) in pharmaceutical formulations, it becomes evident that this compound is more than just an excipient. It has emerged as a crucial component in advancing drug delivery systems and enhancing the efficacy and safety of pharmaceutical products.

CMC-Na, with its unique properties like high viscosity, non-toxicity, and biocompatibility, has proven instrumental in improving drug stability, patient compliance, and overall effectiveness of formulations. Its versatility in various applications, from oral and topical formulations to innovative targeted drug delivery systems, underscores its significance in the pharmaceutical industry.

The ongoing research and development in the field of CMC-Na have continually opened new avenues, addressing challenges like solubility and stability, and enhancing its biocompatibility. The integration of CMC-Na in cutting-edge technologies like nanomedicine and 3D printing indicates a future where personalized medicine and more effective treatments are a reality.

In conclusion, Carboxymethylcellulose Sodium Salt stands as a testament to the evolving nature of pharmaceutical science. Its role in advancing drug formulation technologies is undeniable, marking it as an essential ingredient in the quest for more efficient, safe, and patient-friendly pharmaceutical products. As we look to the future, CMC-Na will undoubtedly continue to be at the forefront of innovation in drug delivery and formulation research.