In the realm of food safety and quality assurance, the detection of additives like Sodium Carboxymethyl Cellulose (CMC) is paramount. This article delves into the standardized methods employed for detecting CMC in food additives, adhering to rigorous analytical protocols.

Sodium Carboxymethyl Cellulose, a common food additive, is used for its thickening and stabilizing properties. However, ensuring its appropriate use and concentration in food products is crucial for consumer health. This necessitates precise and reliable detection methods.

Our approach follows the guidelines set forth by GB/T 601, GB/T 602, and GB/T 603 for the preparation of reagents, standard titration solutions, and impurity determination. These standards ensure accuracy and consistency in detection methodologies. All reagents used, unless specified otherwise, are of analytical grade or higher to guarantee the precision of the results.

The standard solutions for titration and impurity testing are meticulously prepared as per these guidelines. Additionally, the preparations and products used in the experiments adhere to these standards, ensuring the integrity of the detection process.

Water used in the experiments conforms to the Type III water specifications as outlined in GB/T 6682. This adherence to standardized water quality further enhances the reliability of our detection methods. In instances where the solvent for preparing solutions is not explicitly mentioned, it is understood that aqueous solutions are used.

The methods we employ for the detection of Sodium Carboxymethyl Cellulose in food additives are comprehensive and robust. They encompass a range of techniques designed to accurately identify and quantify this additive in various food products. This ensures that food manufacturers comply with safety standards and consumers are protected against potential health risks associated with improper use of food additives.

Through this systematic approach, we aim to contribute significantly to the field of food safety and quality, providing reliable methodologies for the detection of Sodium Carboxymethyl Cellulose in food additives.

Identification Tests

Reagents and Materials

Hydrochloric Acid (HCl).

Potassium Iodide-Iodine Solution: Dissolve 0.5 g of iodine and 1.5 g of potassium iodide in 25 mL of water.

Copper Sulfate (CuSO4.5H2O) Solution: Prepare a solution with a concentration of 20 g/L.

Preparation of the Test Solution

Weigh 2g of the sample and dissolve it in 100 mL of warm water. Stir the mixture until it becomes uniform, and continue stirring until it forms a gel-like consistency. Allow the solution to cool to room temperature.

Identification Methods

Iodine Test: Take approximately 30 mL of the test solution and add 2 to 3 drops of the potassium iodide-iodine solution. The absence of a blue color indicates the presence of Sodium Carboxymethyl Cellulose.

Copper Sulfate Test: Take approximately 50 mL of the test solution and add 10 mL of the copper sulfate solution. The formation of a fluffy light blue precipitate is an indication of the presence of Sodium Carboxymethyl Cellulose.

Flame Test: Moisten a platinum wire with hydrochloric acid and burn it in a colorless flame until it becomes colorless. Then, dip it into the test solution and burn again in a colorless flame. The appearance of a bright yellow flame indicates the presence of Sodium Carboxymethyl Cellulose.

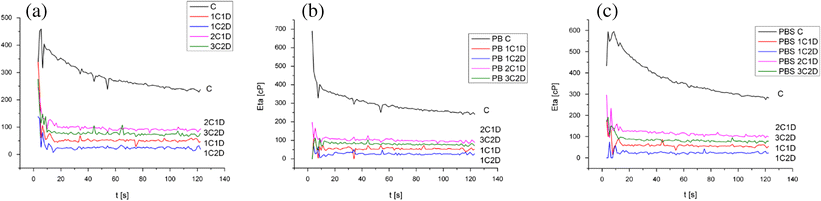

Viscosity Measurement

Instruments and Equipment

Viscometer: Digital or rotary viscometer.

Container: Glass bottle with a consistent diameter (top and bottom) and a capacity of 500 mL.

Constant Temperature Water Bath.

Mechanical Stirrer: Made of stainless steel or glass, attached to a variable-speed electric motor capable of rotating at 900 ±100 rpm under different loads.

Analysis Procedure

Weigh 5.0 g of the sample (to prepare a 1% mass fraction test solution) or 10.0 g (for a 2% mass fraction test solution), accurate to 1 mg. Add 495 mL of water (for a 1% mass fraction solution) or 490 mL (for a 2% mass fraction solution) in a glass beaker. Place the stirrer in the beaker, positioning the stirrer blade about 10 mm from the bottom. Start stirring and gradually add the sample. Adjust the stirring speed to 900 ±100 rpm and continue for 2 hours. If the sample has not completely dissolved, continue stirring for an additional 0.5 hours. Then, remove the stirrer and place the glass beaker in a constant temperature water bath at 25 ±0.2 ℃ for 1 hour. If the solution has not reached the temperature of 25 ±0.2 ℃, continue to maintain this temperature. Afterward, manually stir for 10 seconds and measure the viscosity using the viscometer. Immerse the viscometer rotor in the sample solution, start the viscometer, rotate for about 0.5 minutes, and take the reading when the display stabilizes.

Result Calculation

Digital Viscometer: Directly read the displayed value, which is the viscosity of the sample.

Pointer-Type Viscometer: The viscosity η, expressed in millipascal-seconds (mPa·s), is calculated using formula (A.1):

η=S×k

Where S is the pointer reading of the rotary viscometer, in mPa·s, and k is the coefficient of the rotor and speed used during measurement. The test results should specify the concentration of the test solution and the rotor number and speed used. The results are based on the arithmetic mean of parallel measurements. The absolute difference between two independent measurements under repeatability conditions should not exceed 3% of the arithmetic mean.

Determination of Degree of Substitution

Method Summary

The sample is washed with ethanol to remove soluble salts, dried, and then subjected to high-temperature combustion. The residue, sodium oxide, is dissolved in water to form sodium hydroxide. An excess of sulfuric acid standard titration solution is added, followed by titration with sodium hydroxide standard titration solution to neutralize the excess sulfuric acid. The degree of substitution is calculated as the average number of carboxymethyl groups per anhydrous glucose unit.

Reagents and Materials

Anhydrous Ethanol.

Ethanol Solution: 90 → 100.

Sulfuric Acid Standard Titration Solution: 0.1 mol/L.

Sodium Hydroxide Standard Titration Solution: 0.1 mol/L.

Methyl Red Indicator Solution: 1 g/L.

Instruments and Equipment

Glass Sintered Crucible: Pore size of filter plate 15μm to 40μm.

Porcelain Crucible: 20 mL to 25 mL.

Analysis Procedure

Weigh approximately 1.5 g of the lab sample, accurate to 0.0002 g, and place it in the glass sintered crucible. Wash it several times with ethanol solution preheated to 50 ℃ to 70 ℃ (filling the crucible each time) until the filtrate turns brick-red upon adding a drop of potassium chromate and a drop of silver nitrate solution. If not, continue washing, typically 5 times. After the final wash with anhydrous ethanol, transfer the sample to a flat weighing bottle and dry at 120 ℃ ± 2 ℃ for 2 hours (loosen the sample after about 1 hour). After cooling in a desiccator to room temperature, weigh about 1g of the sample, accurate to 0.2 mg, and place it in a porcelain crucible. Carbonize on an electric furnace until no smoke is emitted, then heat in a high-temperature furnace at 700 ℃ ± 25 ℃ for 15 minutes. After cooling to below 200 ℃, transfer to a 250 mL beaker, add 100 mL of water and 50 mL of sulfuric acid standard titration solution, heat on an electric stove to a gentle boil for 10 minutes, add 2-3 drops of methyl red indicator, cool, and titrate with sodium hydroxide standard titration solution until the red color just fades.

Result Calculation

The degree of substitution (DS) is calculated using formulas (A.2) and (A.3):

CB=(V1C1-V2C2)/m

XD.S=0.162CB/1-0.080CB

Formula Components:

- cB: The molar amount of carboxymethyl per gram of the sample, expressed in millimoles per gram (mmol/g).

- V1: The volume of the sulfuric acid standard titration solution (as per A.5.2.3), in milliliters (mL).

- c1: The precise concentration of the sulfuric acid standard titration solution, in moles per liter (mol/L).

- V2: The volume of the sodium hydroxide standard titration solution (as per A.5.2.4), in milliliters (mL).

- c2: The precise concentration of the sodium hydroxide standard titration solution, in moles per liter (mol/L).

- m: The mass of the sample, in grams (g).

- 0.162: The molar mass of a glucose unit in cellulose, in grams per millimole (g/mmol).

- 0.080: The molar mass of the carboxymethyl sodium group, in grams per millimole (g/mmol).

The calculation results should be expressed to two decimal places. The final result is determined by the arithmetic mean of two parallel determinations, with the absolute difference between them not exceeding 0.02.

Determination of pH

The pH of a 10 g/L sample aqueous solution can be determined either by potentiometric method or using pH paper. For potentiometric measurements, follow the procedure outlined in GB/T 9724. Weigh approximately 1.0 g of the sample, accurate to 0.01 g, and dissolve it in 100 mL of carbon dioxide-free water. Mix the solution thoroughly before measuring the pH.

Determination of Sodium Acetate Content

Method Summary

The sample is processed and its absorbance is measured under the conditions of a wavelength of 540 nm and a 1 cm cuvette.

Reagents and Materials

- Sulfuric Acid.

- Acetic Acid.

- Acetone.

- Sodium Chloride.

- Glacial Acetic Acid.

- 2,7-Dihydroxynaphthalene Solution: Dissolve 0.1 g of 2,7-dihydroxynaphthalene in 1000 mL of concentrated sulfuric acid. Let the solution stand until it becomes clear of any yellow color. Store in a brown reagent bottle for up to 1 month.

- Aluminum Foil Paper.

Instruments and Equipment

- Spectrophotometer.

- Electronic Balance, accuracy of 0.0001 g.

- Water Bath.

- Volumetric Flasks: 25 mL, 100 mL.

Analysis Procedure

Sample Preparation:

Accurately weigh 0.5 g of the sample into a 100 mL beaker. Thoroughly wet it with 5 mL of glacial acetic acid, then add 5 mL of water and stir with a glass rod until completely dissolved (usually takes 15 min). Slowly add 50 mL of acetone while stirring, then add 1 g of sodium chloride and stir for a few minutes to ensure complete precipitation of sodium carboxymethyl cellulose. Filter through a soft, non-dense filter paper moistened with a small amount of acetone, collecting the filtrate in a 100 mL volumetric flask. Use an additional 30 mL of acetone to facilitate the transfer and washing of the solid, then make up to volume with acetone and mix well.

Preparation of Acetic Acid Standard Solution:

Accurately weigh 0.1 g of acetic acid, dried in a desiccator at room temperature for 24 hours, into a 100 mL volumetric flask, dissolve in water, and dilute to the mark. This solution is stable for 1 month. Take 0 mL, 1.0 mL, 2.0 mL, 3.0 mL, 4.0 mL of this solution into five 100 mL volumetric flasks, add water to a total volume of 5 mL, then add 5 mL of glacial acetic acid, and make up to volume with acetone, labeled as solutions 1 to 5.

Procedure:

Take 2.0 mL of the sample solution and solutions 1 to 5 into separate 25 mL volumetric flasks. Place the uncapped flasks in a boiling water bath for 20 minutes to remove acetone, then cool. Add 5 mL of 2,7-dihydroxynaphthalene to each, mix, then add another 15 mL of 2,7-dihydroxynaphthalene, mix again, and seal each flask with aluminum foil. Place back in the boiling water bath for 20 minutes, cool, and make up to volume with concentrated sulfuric acid, then mix well.

Making the Standard Curve

Measure the absorbance of the standard series and the sample solutions using a spectrophotometer with a 1 cm cuvette at 540 nm, using solution 1 as a blank. Establish the standard curve.

Result Calculation

Determine the mass of acetic acid in the sample (m1, in mg) from the standard curve and the absorbance of the sample solution. Calculate the percentage content of sodium acetate (w1) in the sample using the formula (A.4):

W1=[(12.9*M1)/(100-b)]*100%

Where:

- m1 is the mass of acetic acid determined from the standard curve (mg).

- b is the loss on drying (%).

- m0 is the mass of the sample (g).

- 12.9 is the conversion factor from acetic acid to sodium acetate.

Determination of Chloride Content

Method Summary

The sample is dissolved in water and titrated with a standard silver nitrate titration solution, using a potentiometer to indicate the endpoint. Hydrogen peroxide is added to the solution to reduce its viscosity.

Reagents and Materials

- Nitric Acid.

- Hydrogen Peroxide.

- Silver Nitrate Standard Titration Solution: 0.1 mol/L concentration of AgNO3.

Instruments and Equipment

- Potentiometric Titrator: Equipped with a silver electrode and a saturated calomel electrode (double salt bridge).

- Micro Burette: 10 mL.

Analysis Procedure

Weigh 2 g of the sample, dried at 105 ℃ ± 2 ℃ for 2 hours, accurate to 0.0002 g, and place it in a 250 mL beaker. Add 100 mL of water and 5 mL of hydrogen peroxide. Heat the beaker in a steam bath, stirring intermittently to achieve a non-viscous solution. If the viscosity is not completely reduced after 20 minutes, add an additional 5 mL of hydrogen peroxide and heat until completely degraded. Cool the beaker, add 100 mL of water and 10 mL of nitric acid, and place it on the magnetic stirrer of the potentiometric titrator. Titrate with the micro burette using the silver nitrate standard titration solution until the potentiometric endpoint is reached.

Result Calculation

The mass fraction of chloride content (calculated as NaCl) w2 is calculated using

W2=[(CV*M)/m]*100%

Where:

- V is the volume of the silver nitrate standard titration solution, in milliliters (mL).

- c is the concentration of the silver nitrate standard solution, in moles per liter (mol/L).

- m is the mass of the sample, in grams (g).

- M is the molar mass of sodium chloride, 0.05845 g/mmol.

The results are expressed to one decimal place. The final result is the arithmetic mean of two parallel determinations, with the absolute difference between them not exceeding 0.06%.

FAQ

What is the purpose of the hydrogen peroxide in the chloride content determination method?

Hydrogen peroxide is used to reduce the viscosity of the solution, making it easier to handle and ensuring accurate titration results.

Can I use any spectrophotometer for the sodium acetate content determination?

A spectrophotometer capable of measuring at a wavelength of 540 nm with a 1 cm cuvette is required for accurate determination

What is the significance of using a double salt bridge in the potentiometric titrator for chloride content determination?

A double salt bridge in the potentiometric titrator enhances the accuracy and stability of the electrode potential, leading to more precise measurements.

Why is it necessary to dry the sodium acetate sample for 24 hours before its standard solution preparation?

Drying the sample for 24 hours ensures the removal of moisture, which could otherwise affect the concentration and accuracy of the standard solution.

How do I ensure complete precipitation of sodium carboxymethyl cellulose in the sodium acetate content determination method?

Ensure complete precipitation by adding 1 g of sodium chloride and stirring for a few minutes after the addition of acetone to the sample solution.

What is the role of 2,7-dihydroxynaphthalene in the sodium acetate content determination?

2,7-Dihydroxynaphthalene is used to react with sodium acetate, forming a colored complex that can be measured spectrophotometrically.

Why is it important to use carbon dioxide-free water in pH measurement of a sample solution?

Carbon dioxide can alter the pH of the solution, so using carbon dioxide-free water ensures that the pH measured is solely due to the sample.

How do I calculate the degree of substitution in the carboxymethyl cellulose sample?

The degree of substitution is calculated based on the average number of carboxymethyl groups per anhydrous glucose unit, using specified formulas and titration results.

What is the significance of the molar mass of sodium chloride (0.05845 g/mmol) in the chloride content calculation?

The molar mass of sodium chloride is used to convert the measured chloride ion concentration to the equivalent mass fraction of sodium chloride in the sample.

Summary

This summary covers various analytical methods for determining the properties of chemical samples. Techniques include potentiometric titration for chloride content, spectrophotometric analysis for sodium acetate, and pH measurement using a potentiometer or pH paper. Each method requires specific reagents, such as hydrogen peroxide to reduce solution viscosity and 2,7-dihydroxynaphthalene for colorimetric analysis. Key equipment includes a spectrophotometer, potentiometric titrator, and precise measuring instruments like micro burettes and electronic balances. The procedures emphasize accuracy in sample preparation, titration, and calculation of results, with each step carefully designed to ensure the reliability and precision of the measurements. These methods collectively provide a comprehensive approach to analyzing and verifying the composition and characteristics of chemical samples.

Recommended

“Quantitative Chemical Analysis” by Daniel C. Harris:This book is a comprehensive resource for understanding the principles and techniques of quantitative analysis, including titration methods, spectrophotometry, and pH measurement.

“Fundamentals of Analytical Chemistry” by Douglas A. Skoog, Donald M. West, F. James Holler, and Stanley R. Crouch:This text offers in-depth coverage of analytical chemistry with a focus on the practical aspects of chemical analysis and instrumental methods.

“Vogel’s Textbook of Quantitative Chemical Analysis” by G. H. Jeffery, J. Basset, J. Mendham, and R. C. Denney:A classic textbook that provides detailed procedures and methodologies for various types of chemical analyses, including titrimetric and spectrophotometric methods.

“Practical Handbook of Spectroscopy” edited by James W. Robinson:This handbook is a valuable resource for understanding the applications of spectroscopy in chemical analysis, including detailed discussions on spectrophotometric techniques.

“Analytical Chemistry” by Gary D. Christian, Purnendu K. (Sandy) Dasgupta, and Kevin A. Schug:This book provides a thorough introduction to modern analytical chemistry with a focus on how to solve analytical problems, covering a range of techniques including potentiometry and other titration methods.