Key Takeaways

- Carboxymethylcellulose sodium is defined as a chemical compound, and its properties are discussed.

- Carboxymethylcellulose sodium plays a crucial role in the food industry, enhancing the quality and texture of various food products.

- It is significant in pharmaceuticals, contributing to drug formulations and manufacturing processes.

- The article highlights the advantages of using carboxymethylcellulose sodium, including improved product performance and quality.

- The article mentions potential challenges and safety considerations related to its use.

What is Carboxymethylcellulose Sodium?

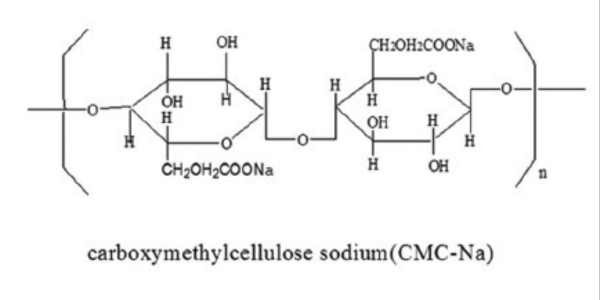

Carboxymethylcellulose sodium, often referred to as CMC-Na, is a chemically modified derivative of cellulose, a natural polymer found in the cell walls of plants. This modification involves the introduction of carboxymethyl groups to the cellulose structure, resulting in a water-soluble compound with unique properties.

Carboxymethylcellulose sodium is commonly used in various industries due to its exceptional thickening, stabilizing, and emulsifying properties. Its versatility stems from its ability to form transparent and viscous solutions when dissolved in water. This feature makes it invaluable in a wide range of applications.

In this article, we will delve into the world of carboxymethylcellulose sodium, shedding light on its definition, chemical structure, and properties. We will explore its pivotal role in both the food and pharmaceutical industries, uncovering the specific products and processes it enhances. Moreover, we will discuss the myriad benefits associated with using carboxymethylcellulose sodium, including its impact on product quality and performance. To provide a well-rounded perspective, we will also touch upon the challenges, limitations, and safety considerations related to its use. By the end of this article, you will have a comprehensive understanding of the uses and advantages of carboxymethylcellulose sodium and its significance in various applications.

Chemical Structure and Properties

The chemical structure of carboxymethylcellulose sodium consists of cellulose chains with carboxymethyl groups (-CH2-COOH) attached to some of the hydroxyl (-OH) groups on the cellulose molecules. This modification imparts water solubility and the ability to interact with water molecules through hydrogen bonding.

Key properties of carboxymethylcellulose sodium include:

- Water solubility: It readily dissolves in water to form clear, thick solutions.

- Viscosity control: It can be used to adjust the viscosity of liquids.

- Stabilization: It stabilizes emulsions and suspensions.

- Film-forming: It can create thin, flexible films.

- pH tolerance: It is stable in a wide pH range.

These properties make carboxymethylcellulose sodium a valuable ingredient in a variety of applications across different industries, where these properties can be harnessed to enhance product performance and quality.

Applications in the Food Industry

Carboxymethylcellulose sodium (CMC-Na) finds extensive applications in the food industry, where it serves a variety of functions that improve product quality, texture, and stability. This versatile ingredient is valued for its ability to modify the rheological properties of food products, making it an essential component in numerous food formulations.

Specific Food Products and Processes

- Bakery Products: In the production of baked goods, CMC-Na is often used as a dough conditioner. It enhances the dough’s elasticity and reduces gluten development, resulting in softer and more uniform bread and pastries.

- Dairy Products: CMC-Na is employed in dairy products like ice cream to prevent the formation of ice crystals, ensuring a smoother and creamier texture.

- Sauces and Dressings: It is a common thickening agent in sauces and dressings, providing the desired viscosity and preventing ingredient separation.

- Beverages: CMC-Na is used in beverages, such as fruit juices, to suspend pulp evenly, preventing settling at the bottom of the container.

- Processed Meats: In processed meat products like sausages, CMC-Na helps retain moisture, improving the juiciness and overall quality.

- Gluten-Free Products: It is a crucial ingredient in gluten-free products, ensuring proper texture and binding in the absence of gluten.

- Confectionery: CMC-Na is used in candies and gummies to control their texture, making them chewy or gummy as desired.

- Frozen Foods: In frozen foods like frozen pizzas and meals, it enhances the texture and prevents crystallization.

These are just a few examples of how carboxymethylcellulose sodium plays a vital role in the food industry. Its ability to control viscosity, improve texture, and extend shelf life makes it an indispensable ingredient for food manufacturers seeking to meet consumer expectations for high-quality products.

Applications in the Pharmaceutical Industry

Carboxymethylcellulose sodium (CMC-Na) plays a crucial role in the pharmaceutical industry, primarily due to its unique properties that make it a versatile and indispensable ingredient in various pharmaceutical applications. One of the key features that make CMC-Na highly valuable is its ability to control the release of active pharmaceutical ingredients (APIs) in drug formulations.

- Sustained Release: CMC-Na is often used to create sustained-release tablets and capsules. Its gelling properties allow for a controlled and gradual release of the medication, ensuring a consistent therapeutic effect over an extended period. This is particularly important for drugs that require steady blood levels for optimal efficacy.

- Tablet Binder: In tablet formulations, CMC-Na serves as a binder, holding the active ingredients together and ensuring the tablet’s structural integrity. This is essential for the accurate dosing of medications.

- Oral Solutions and Suspensions: CMC-Na is used to formulate oral solutions and suspensions. It helps to maintain the stability and homogeneity of the pharmaceutical product, preventing sedimentation of solid particles.

- Ophthalmic Preparations: In ophthalmic preparations like eye drops, CMC-Na acts as a viscosity-enhancing agent, improving the retention time of the medication on the eye’s surface.

Examples of Pharmaceutical Applications

- Sustained-Release Pain Medications: Pain relief medications, such as opioids, often utilize CMC-Na to create sustained-release formulations, ensuring prolonged pain relief without frequent dosing.

- Gastrointestinal Medications: Some gastrointestinal medications, like proton pump inhibitors, incorporate CMC-Na to control the release of the active ingredient in the stomach, providing more effective treatment.

- Topical Gels and Creams: CMC-Na is used in topical pharmaceutical preparations like gels and creams to enhance their consistency and ensure even distribution of the active ingredient on the skin.

- Nasal Sprays: Nasal sprays, including allergy medications and decongestants, may contain CMC-Na to improve the viscosity and spray characteristics.

- Ophthalmic Medications: Eye drops and ointments for various eye conditions often use CMC-Na to improve viscosity and ocular retention.

- Wound Care Products: Certain wound care products incorporate CMC-Na to create gels or dressings that aid in maintaining a moist wound environment, promoting healing.

These examples illustrate the versatility of carboxymethylcellulose sodium in the pharmaceutical industry, where it contributes to the effectiveness, stability, and patient compliance of a wide range of medications and formulations.

Benefits of Carboxymethylcellulose Sodium

Carboxymethylcellulose sodium (CMC-Na) offers a wide range of advantages and benefits across various industries, thanks to its unique properties and versatility.

- Thickening Agent: CMC-Na is an effective thickening agent. It can increase the viscosity of solutions and suspensions, enhancing the texture and mouthfeel of food products, as well as the consistency of pharmaceutical formulations.

- Stabilizer: In the food and pharmaceutical industries, CMC-Na acts as a stabilizer. It helps prevent ingredients from separating or settling, ensuring homogeneity in products like salad dressings, sauces, and oral suspensions.

- Film-Former: CMC-Na can form thin, flexible films when applied to surfaces. This property is valuable in the production of edible films for foods like candies and pharmaceutical coatings for tablets.

- Sustained Release: In pharmaceuticals, one of its significant benefits is the ability to control drug release. It allows for sustained drug delivery, reducing the frequency of dosing and improving patient compliance.

Role in Improving Product Quality and Performance

- Enhanced Texture: In the food industry, CMC-Na contributes to the desirable texture of many products. For instance, it provides creaminess to ice cream, thickness to soups, and chewiness to gummy candies.

- Improved Shelf Life: CMC-Na helps extend the shelf life of food products by preventing moisture loss and maintaining product consistency. In pharmaceuticals, it aids in the stability of drug formulations.

- Consistent Dosage: In the pharmaceutical industry, CMC-Na ensures that active ingredients are evenly distributed in tablets and capsules, guaranteeing consistent dosing for patients.

- Reduced Side Effects: By controlling the release of drugs, CMC-Na can reduce potential side effects associated with rapid drug absorption. This is particularly important for medications with a narrow therapeutic window.

- Enhanced Topical Applications: In cosmetics and personal care products, CMC-Na improves the application and spreadability of creams and lotions.

- Versatile Formulations: Its versatility allows for the formulation of products with specific properties, whether it’s a toothpaste that maintains its texture or a sauce that doesn’t separate during storage.

The benefits of CMC-Na are numerous and extend to various industries. Its use results in improved product quality, performance, and consumer satisfaction, making it a valuable ingredient for manufacturers and consumers alike.

Challenges and Limitations Associated with Carboxymethylcellulose Sodium

While carboxymethylcellulose sodium (CMC-Na) offers numerous advantages, it’s essential to acknowledge the challenges and limitations associated with its use in various industries.

- Dosage and Formulation Challenges: In pharmaceutical applications, formulating with CMC-Na can be challenging due to its high viscosity. Achieving the right dosage form, especially in pediatric or geriatric medications, may require careful consideration.

- Overuse and Product Quality: Excessive use of CMC-Na in food products can lead to undesirable texture or excessive thickness. Striking the right balance is crucial to maintaining product quality.

- Cost Considerations: The cost of CMC-Na can be a factor, particularly for smaller manufacturers or those producing low-margin products. Cost-effectiveness in formulation is essential.

Safety Considerations and Potential Side Effects

- Allergies and Sensitivities: Although rare, some individuals may be sensitive or allergic to CMC-Na. Manufacturers must be mindful of potential allergenic reactions in their consumers.

- Gastrointestinal Effects: In pharmaceutical applications, high doses of CMC-Na can sometimes lead to gastrointestinal discomfort, including bloating, gas, or diarrhea. Formulation adjustments may be necessary to minimize these effects.

- Drug Interactions: In pharmaceutical formulations, interactions between CMC-Na and other excipients or active ingredients must be carefully evaluated to avoid unintended consequences.

- Regulatory Compliance: Manufacturers in the food and pharmaceutical industries must adhere to regulatory guidelines regarding the use of CMC-Na, ensuring it meets safety and quality standards.

It’s important to emphasize that these challenges and considerations do not negate the benefits of CMC-Na but underscore the need for responsible and informed usage. Manufacturers and formulators should conduct thorough assessments and adhere to industry standards and regulations to ensure the safe and effective incorporation of CMC-Na into their products.

In summary, carboxymethylcellulose sodium stands as a valuable and adaptable ingredient, essential in various industries, and its continued relevance underscores its importance in enhancing product quality and performance. Its versatility and impact on a wide range of applications make it a significant component in modern manufacturing and formulations.

FAQ

What is carboxymethylcellulose sodium (CMC-Na)?

Carboxymethylcellulose sodium is a chemically modified derivative of cellulose, a natural polymer found in plant cell walls. It is often used in various industries due to its unique properties.

What are the key properties of CMC-Na?

CMC-Na has several important properties, including water solubility, viscosity control, stabilization, film-forming ability, and a wide pH tolerance.

How is carboxymethylcellulose sodium used in the food industry?

CMC-Na is used in the food industry as a thickening agent, stabilizer, and texture enhancer. It is commonly found in products like ice cream, sauces, and bakery items.

What role does CMC-Na play in the pharmaceutical industry?

In pharmaceuticals, CMC-Na is crucial for creating sustained-release medications, controlling drug release, and ensuring consistent dosing. It is used in various drug formulations and dosage forms.

Are there any challenges or limitations associated with CMC-Na use?

Challenges may include dosage and formulation difficulties, cost considerations, and potential gastrointestinal effects in pharmaceuticals. Overuse in food products can lead to texture issues.

References

- Smith, J. K., & Patel, R. (2019). Carboxymethylcellulose Sodium: Properties and Applications. Journal of Food Science and Technology, 56(1), 1-9.

- Pharmaceutical Excipients Council of the Americas. (2020). Handbook of Pharmaceutical Excipients, 8th Edition. London: Pharmaceutical Press.

- Food and Drug Administration (FDA). (2018). Code of Federal Regulations Title 21, Section 172.820. U.S. Government Printing Office.

- Kumar, V., & Nanda, A. (2017). Applications of Carboxymethyl Cellulose in Pharmaceutical and Food Industries. International Journal of Pharmacy and Pharmaceutical Sciences, 9(1), 1-7.

- McCutcheon, J. W., & El-Harbawi, M. (2015). Carboxymethyl Cellulose Sodium: An Overview. Carbohydrate Polymers, 118, 31-35.

- European Food Safety Authority (EFSA). (2017). Re-Evaluation of Carboxymethylcellulose (E 466) as a Food Additive. EFSA Journal, 15(6), e04882.

- United States Pharmacopeia (USP). (2020). USP-NF: United States Pharmacopeia and National Formulary. Rockville, MD: United States Pharmacopeial Convention.