Introduction

The oil drilling industry, a critical component of the global energy sector, faces continuous challenges in optimizing efficiency, reducing costs, and minimizing environmental impact. In this complex equation, drilling mud plays a pivotal role, serving as the lifeblood of drilling operations. Among the various additives used in drilling mud, Carboxymethyl Cellulose (CMC) stands out due to its unique properties and advantages.

Carboxymethyl Cellulose, a cellulose derivative with carboxymethyl groups (-CH2-COOH) bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone, has gained significant importance in drilling operations. Its role in enhancing drilling fluid efficiency is paramount. This introduction will provide a brief overview of the challenges in the oil drilling industry, followed by an insight into CMC and its application in drilling muds.

The challenges in oil drilling range from drilling through complex geological formations to ensuring the safety of the operations. Each step of the drilling process demands precision, efficiency, and a keen understanding of the subsurface conditions. Drilling mud, which is circulated through the wellbore during drilling operations, assists in lubricating the drill bit, carrying drill cuttings to the surface, stabilizing the wellbore walls, and controlling pressure. The choice of drilling mud composition is therefore crucial for the success of drilling operations.

CMC, when used in drilling mud, primarily functions to control fluid loss. It forms a thin, yet tough, filter cake on the walls of the wellbore, which prevents the fluid from seeping into the formation. This is particularly essential in maintaining wellbore stability and preventing blowouts, a dangerous occurrence in drilling operations. Furthermore, CMC increases the viscosity of the mud, which improves the removal of cuttings from the wellbore and aids in the protection of the drill bit.

Additionally, CMC’s properties of being biodegradable and non-toxic contribute significantly to making the drilling process more environmentally friendly. Its effectiveness in a wide range of temperatures and pH levels makes it an adaptable solution in various drilling environments.

The introduction sets the stage for a detailed exploration into the multifaceted role of CMC in drilling mud. The subsequent sections will delve deeper into its impact on drilling efficiency, environmental safety, cost-effectiveness, and the challenges it addresses. The exploration will further extend into the future prospects and innovations in the use of CMC in oil drilling, underlining its significance in revolutionizing drilling operations and contributing towards a more efficient and sustainable oilfield industry.

What is Drilling Mud?

Drilling mud, often considered the cornerstone of drilling operations in the oilfield industry, is not just a mere fluid but a sophisticated blend engineered to meet the diverse challenges of drilling operations. Understanding its composition, functionality, and types is essential for grasping the role of CMC in enhancing its performance.

Primarily, drilling mud serves multiple critical functions: it lubricates and cools the drill bit, carries the drill cuttings to the surface, stabilizes the wellbore walls, and balances formation pressure to prevent blowouts. This mud is a carefully formulated mixture comprising a base fluid (water, oil, or synthetic compounds), clays, and various chemical additives, each serving a specific purpose.

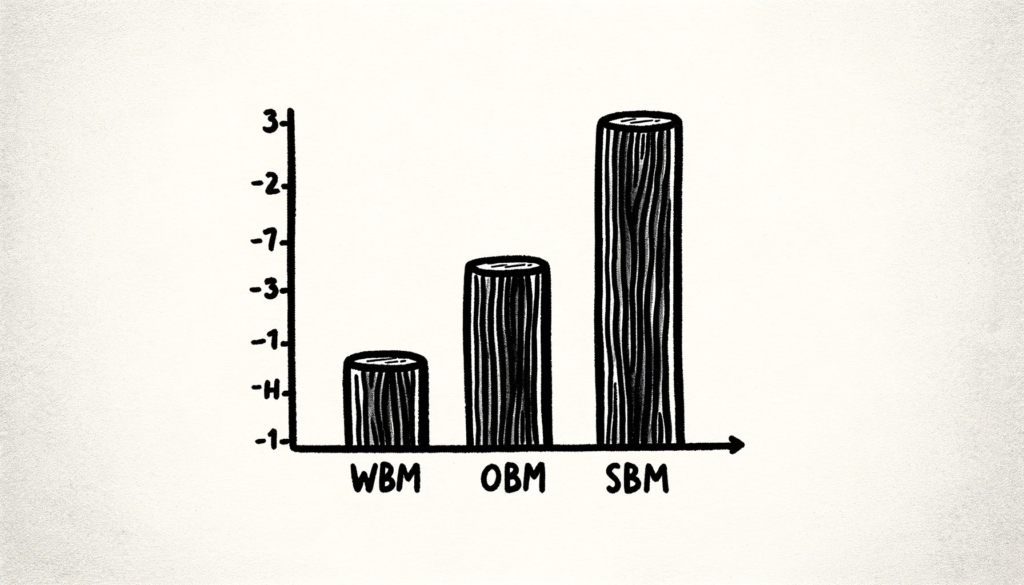

The types of drilling mud are broadly classified into water-based muds (WBM), oil-based muds (OBM), and synthetic-based muds (SBM). WBM, the most commonly used type, is favored for its cost-effectiveness and minimal environmental impact. It consists of water as the continuous phase and clays and other chemicals dispersed in it. OBM, on the other hand, uses oil as the base fluid and is preferred for its high thermal stability, which is crucial for deep and high-temperature wells. SBM combines the best of both, offering reduced environmental impact while maintaining high performance.

The functionality of drilling mud is complex. It must possess the right viscosity to carry cuttings effectively, maintain sufficient hydrostatic pressure to counterbalance formation pressures, and have the right density to prevent well collapse or blowout. Furthermore, the mud must minimize damage to the formation, ensuring optimal extraction of oil or gas.

In this intricate matrix, the role of additives like CMC becomes pivotal. CMC, when added to drilling mud, primarily enhances its rheological properties – the fluid’s flow behavior. By increasing the mud’s viscosity, CMC aids in better suspension of drill cuttings, ensuring they are efficiently transported to the surface for removal. Additionally, it improves the mud’s ability to form a robust filter cake on the wellbore walls, which is critical for maintaining wellbore stability and preventing fluid loss into the formation.

Another vital aspect of drilling mud is its environmental impact. As the industry moves towards more eco-friendly practices, the selection of mud components that are biodegradable and non-toxic becomes increasingly important. CMC, being a natural polysaccharide, is biodegradable and poses minimal environmental risk compared to synthetic polymers.

Understanding the complex nature of drilling mud and its vital role in the oil drilling process sets the foundation for appreciating the significant impact of CMC as an additive. Its ability to enhance mud properties, ensure operational safety, and align with environmental standards highlights its indispensable role in modern drilling operations.

The Role of CMC in Drilling Mud

Carboxymethyl Cellulose (CMC) plays a transformative role in the composition and functionality of drilling mud, positioning itself as an indispensable component in modern oil drilling operations. This section explores the unique properties of CMC that make it so valuable in drilling mud and how it addresses specific drilling challenges.

CMC, a water-soluble polymer derived from natural cellulose, is renowned for its excellent thickening, stabilizing, and water-retaining properties. When introduced into drilling mud, CMC serves several critical functions. Firstly, it acts as a viscosity modifier. By increasing the viscosity of the drilling fluid, CMC ensures a more effective suspension of drill cuttings and aids in their transport to the surface. This is crucial for maintaining the efficiency and cleanliness of the drilling operation.

Another vital function of CMC in drilling mud is fluid loss control. During drilling, there is always a risk of the drilling fluid leaking into the surrounding formations, which can lead to a decrease in mud density and potential well control issues. CMC combats this by forming a thin, low-permeability filter cake on the walls of the wellbore. This filter cake acts as a barrier, preventing the fluid from seeping into the formation and maintaining the integrity of the well.

The ability of CMC to improve the mud’s thermal stability is also significant, especially in deep and high-temperature drilling environments. It helps in maintaining the consistency and effectiveness of the drilling fluid under varying temperature conditions, which is essential for operational success in challenging environments.

Moreover, CMC contributes to the lubricating properties of the drilling mud, reducing friction between the drill string and the wellbore. This reduction in friction not only prolongs the life of the drilling equipment but also enhances the rate of penetration, further increasing operational efficiency.

From an environmental perspective, the use of CMC is advantageous. Being a natural, biodegradable polymer, CMC is a more environmentally friendly alternative to synthetic additives. Its non-toxic nature reduces the ecological impact of drilling operations, aligning with the industry’s increasing focus on sustainability.

The role of CMC in drilling mud cannot be overstated. Its multifunctional properties address several key challenges in drilling operations, from improving efficiency and safety to enhancing environmental compatibility. Its application in drilling mud exemplifies how a single additive can significantly impact the overall performance of such a crucial aspect of the oil drilling process.

Improving Drilling Efficiency with CMC

The enhancement of drilling efficiency is a critical goal in the oilfield industry, and Carboxymethyl Cellulose (CMC) plays a pivotal role in achieving this objective. This section delves into how CMC improves drilling speed, precision, and overall operational efficiency, including insights from real-world case studies.

CMC’s impact on drilling efficiency is multifaceted. Firstly, its viscosity-enhancing properties play a crucial role. By increasing the viscosity of drilling mud, CMC ensures a more effective suspension and transport of drill cuttings. This leads to cleaner and more efficient drilling, as the drill bit can cut through the geological formations more effectively without being bogged down by debris.

In terms of drilling speed, the lubricating properties of CMC are invaluable. Reduced friction between the drill string and the wellbore walls not only prevents wear and tear on the equipment but also facilitates faster drilling. The less resistance the drill bit encounters, the quicker it can penetrate through the earth’s layers.

Precision in drilling is another area where CMC shows its strength. The stability it provides to the drilling mud composition allows for more accurate drilling. A stable mud viscosity ensures consistent hydrostatic pressure, which is crucial for precise wellbore placement. This accuracy is vital in complex drilling environments where hitting the target zone is challenging and requires exact drilling paths.

Case studies in various oilfields demonstrate the effectiveness of CMC. For instance, in a particular offshore drilling operation, the introduction of CMC led to a noticeable increase in the rate of penetration, reducing overall drilling time and costs. In another onshore project, the use of CMC-based mud resulted in a significant reduction in non-productive time, attributed to fewer instances of equipment failure and well control issues.

The economic benefits of CMC use in drilling operations are also noteworthy. While it adds an additional component to the mud composition, the overall cost savings from increased efficiency, reduced equipment wear, and shorter drilling times more than compensate for the initial investment. Additionally, the potential reduction in environmental impact and associated compliance costs further enhances its economic attractiveness.

CMC’s contribution to improving drilling efficiency is substantial. Its ability to enhance drilling speed, precision, and overall operational effectiveness makes it a valuable asset in the oilfield industry. Case studies and economic analyses reinforce the argument for its widespread adoption, highlighting CMC as a key ingredient in the quest for more efficient and cost-effective drilling operations.

Environmental and Safety Aspects

The environmental and safety aspects of drilling operations have become increasingly important in the oilfield industry, and Carboxymethyl Cellulose (CMC) significantly contributes to these areas. This section explores how the use of CMC in drilling mud aligns with environmental sustainability and enhances safety in drilling operations.

Environmental sustainability is a pressing concern in the oil and gas industry. The use of CMC in drilling mud addresses this concern in several ways. As a natural, biodegradable polymer, CMC breaks down into non-toxic components, reducing the environmental footprint of drilling operations. This contrasts sharply with synthetic additives, which may pose environmental risks due to their non-biodegradable and potentially toxic nature.

The application of CMC in drilling mud also contributes to the reduction of fluid loss during drilling. By forming an effective filter cake on the wellbore walls, CMC minimizes the leakage of drilling fluids into surrounding formations. This not only conserves valuable drilling fluid but also protects the subsurface environment from potential contamination.

Furthermore, the use of CMC enhances the recyclability of drilling mud. Due to its stabilizing properties, drilling mud with CMC maintains its consistency and effectiveness over longer periods. This reduces the need for frequent disposal and replacement, consequently lowering the environmental impact associated with mud disposal and production.

From a safety perspective, CMC plays a crucial role in ensuring the integrity and stability of drilling operations. Its ability to stabilize the viscosity of drilling mud is vital in maintaining wellbore stability, thereby reducing the risk of well collapse or blowouts. These events can have catastrophic consequences, not only for the drilling personnel but also for the environment.

CMC’s contribution to drilling safety is also seen in its impact on equipment longevity and maintenance. By reducing the wear and tear on drilling equipment through enhanced lubrication, CMC decreases the likelihood of equipment failure, which is a significant safety concern in drilling operations.

The non-toxic nature of CMC is an additional safety benefit, especially for workers handling drilling mud. Unlike some chemical additives that pose health risks through exposure, CMC’s safety profile ensures a healthier and safer working environment for the drilling crew.

The environmental and safety benefits of using CMC in drilling operations are substantial. Its biodegradable nature, contribution to drilling fluid conservation, and safety enhancements in terms of wellbore stability and equipment longevity position CMC as a key component in the pursuit of more environmentally sustainable and safer drilling practices. These benefits not only align with the industry’s growing environmental and safety consciousness but also add value in terms of operational efficiency and cost-effectiveness.

Cost-Effectiveness of CMC in Drilling Operations

In the oil and gas industry, where cost optimization is crucial, the use of Carboxymethyl Cellulose (CMC) in drilling mud represents a significant step toward cost-effectiveness. This section discusses the economic benefits of CMC in drilling operations, including a comparison with other drilling mud additives and an analysis of long-term financial impacts.

The initial aspect to consider is the direct cost of CMC as an additive. While CMC might have a higher upfront cost compared to some traditional mud additives, its efficiency in usage and the benefits it brings to drilling operations result in overall cost savings. For example, the ability of CMC to improve the viscosity and stability of drilling mud reduces the quantity of other additives required, leading to a decrease in the total cost of mud composition.

Moreover, the effective fluid loss control provided by CMC results in less drilling fluid being wasted. This not only conserves the amount of drilling mud needed but also minimizes the costs associated with mud production and disposal. Given the high cost of drilling fluids, this represents a significant saving.

The impact of CMC on drilling speed and equipment maintenance also contributes to its cost-effectiveness. Faster drilling rates and reduced downtime due to equipment failure or maintenance lead to a more efficient drilling process, saving both time and money. In an industry where operational time is costly, these efficiency improvements translate directly into financial benefits.

Comparing CMC with other drilling mud additives, its advantages become apparent. While some additives may offer similar benefits in certain aspects, CMC’s combination of effective viscosity control, fluid loss prevention, and environmental compatibility is unique. Additionally, the reduced environmental and health risks associated with CMC can lead to lower insurance costs and compliance expenses, further enhancing its cost-effectiveness.

Long-term financial benefits for oilfields using CMC-based drilling mud are also significant. The improved efficiency and safety of drilling operations contribute to a reduction in overall project costs. Additionally, the environmental friendliness of CMC can lead to a positive company image and potentially better relationships with regulatory bodies, which can have indirect financial benefits.

Challenges and Solutions in Using CMC

While Carboxymethyl Cellulose (CMC) offers numerous advantages in drilling operations, its implementation is not without challenges. This section discusses common obstacles encountered when using CMC in drilling mud and explores potential solutions and best practices to address these issues.

One of the primary challenges in using CMC is ensuring its optimal performance under various drilling conditions. Different geological formations and drilling environments require specific mud properties, and CMC must be carefully tailored to meet these varying demands. In some cases, high temperatures or extreme pH conditions can affect the effectiveness of CMC, necessitating adjustments in its formulation.

To address this, ongoing research and development are crucial. Innovations in CMC formulations can enhance its stability and performance in a wider range of conditions. Collaboration with chemical suppliers to develop more robust variants of CMC can ensure consistent performance even under challenging drilling scenarios.

Another challenge is the compatibility of CMC with other mud additives. CMC can interact with certain chemicals, potentially altering the desired properties of the drilling mud. This necessitates a thorough understanding of mud chemistry and careful planning when formulating the mud composition.

Best practices in this regard include conducting comprehensive laboratory tests to assess the compatibility of CMC with other additives. Additionally, field trials and pilot tests can provide valuable insights into how CMC behaves in real drilling conditions, allowing for fine-tuning of the mud formulation.

The cost-effectiveness of CMC, while advantageous in the long run, can be a challenge upfront. The initial investment in high-quality CMC and the necessary research for optimal formulation may deter some operators, especially in a cost-sensitive industry.

To overcome this, a clear communication of the long-term cost benefits is essential. Demonstrating how the use of CMC can lead to overall savings through improved efficiency, reduced equipment wear, and lower environmental impact can help in justifying the initial expenditure.

Handling and storage of CMC also pose practical challenges. Being a hygroscopic material, CMC can absorb moisture from the air, leading to clumping or degradation of its properties. Proper storage conditions and handling procedures are essential to maintain its quality.

Best practices here involve storing CMC in a cool, dry environment and using sealed containers to prevent moisture ingress. Proper training for personnel handling CMC is also crucial to ensure that it is used and stored correctly.

While the use of CMC in drilling operations presents certain challenges, these can be effectively managed through innovation, careful planning, and adherence to best practices. Addressing these challenges not only ensures the optimal performance of CMC but also maximizes the benefits it brings to drilling operations, reinforcing its role as a valuable additive in the oilfield industry.

Conclusion

The exploration of Carboxymethyl Cellulose (CMC) in drilling mud throughout this article underscores its critical role in enhancing the efficiency and sustainability of oilfield operations. This concluding section summarizes the key insights and reiterates the overarching importance of CMC in modern drilling practices.

CMC’s role in drilling mud is multifaceted and impactful. Its ability to improve the viscosity and stability of drilling fluids leads to more efficient and cleaner drilling operations, enhancing the overall productivity of oil extraction. By facilitating better control over fluid loss and providing stability to the wellbore, CMC contributes significantly to operational safety, reducing the risks of well collapse and blowouts.

The environmental aspect of CMC’s application cannot be overstated. As a biodegradable and non-toxic additive, it represents a shift towards more environmentally responsible drilling practices. The oil and gas industry, increasingly aware of its environmental responsibilities, finds in CMC a solution that aligns with sustainability goals without compromising on efficiency.

Economically, the use of CMC presents a compelling case. Although its initial cost may be higher compared to some traditional additives, the long-term savings achieved through improved drilling efficiency, reduced equipment wear, and minimized environmental impact make CMC a cost-effective choice. Its value proposition is further strengthened by its adaptability to different drilling conditions and its contribution to extending the lifespan of drilling mud.

The challenges associated with the use of CMC, including handling and compatibility issues, are manageable with the right practices and ongoing innovation. The industry’s commitment to addressing these challenges through research and development, improved formulations, and best practices ensures that CMC continues to be an effective tool in oil drilling operations.

Looking ahead, the future of CMC in oil drilling is marked by potential advancements in formulations, application methods, and integration with digital technologies. The continuous evolution of CMC to meet the changing demands of the oilfield industry underscores its enduring relevance.

In summary, Carboxymethyl Cellulose is much more than just an additive; it is a key enabler in the quest for more efficient, safer, and environmentally friendly drilling operations. Its multifunctional properties, economic benefits, and alignment with environmental standards make it an indispensable component in modern drilling muds. As the oil and gas industry continues to face new challenges and evolve, the role of CMC is likely to grow, further cementing its position as a critical element in the future of oilfield drilling.