Introduction

The dawn of the 21st century has witnessed a phenomenal surge in the demand for efficient and reliable energy storage systems, predominantly driven by the exponential growth of portable electronic devices, electric vehicles (EVs), and renewable energy systems. Central to this technological revolution are lithium-ion batteries, known for their high energy density, light weight, and long cycle life. However, the quest for even higher performance and safer battery technologies has led to continuous innovation in battery materials and manufacturing processes.

One such innovation is the integration of Carboxymethyl Cellulose (CMC) into the fabrication of the battery’s anode, the negative electrode in the battery. CMC, a derivative of cellulose, has emerged as a game-changer in the realm of battery manufacturing. It serves a dual role as a thickening and anti-settling agent, essential for the creation of high-quality electrodes. The choice of binder materials like CMC in the anode significantly influences the battery’s overall performance, durability, and safety.

In this article, we will delve into the pivotal role of CMC in revolutionizing lithium-ion battery technology. We will explore how CMC contributes to the stability and efficiency of the anode, and by extension, to the battery as a whole. Our journey will take us through the fundamental components of a lithium-ion battery, the unique properties of CMC that make it an indispensable material in anode manufacturing, and the broader implications of its use in advancing battery technology.

Overview of Lithium-Ion Battery Components

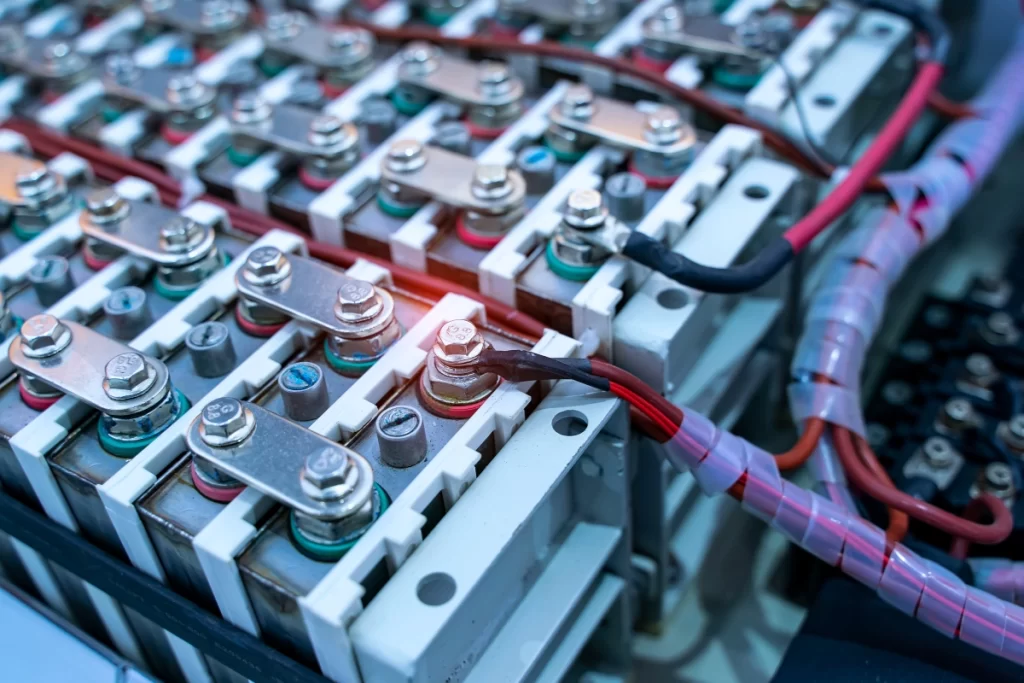

Lithium-ion batteries are the powerhouse behind a wide range of modern technologies, from smartphones to electric cars. At their core, these batteries are made up of several key components, each playing a critical role in their operation. The four main components are the anode (negative electrode), cathode (positive electrode), electrolyte, and separator.

The Anode and Cathode: The anode and cathode are where the lithium ions are stored. The anode, typically made from carbon materials like graphite, is where lithium ions are held during the battery’s discharge cycle. During charging, these ions move back to the cathode, which is usually composed of a lithium metal oxide. The performance of these electrodes is crucial for the battery’s capacity, output voltage, and overall efficiency.

The Electrolyte: The electrolyte is a chemical medium that allows the transfer of lithium ions between the cathode and anode when the battery charges and discharges. This ionic movement is what generates electrical power. The electrolyte’s composition significantly affects the battery’s performance, safety, and longevity.

The Separator: Acting as a physical barrier between the anode and cathode, the separator prevents short circuits while allowing the free movement of lithium ions. It is typically made from a porous polymer film.

The intricate balance and interplay between these components determine the overall performance of a lithium-ion battery. Innovations in any of these components can lead to significant improvements in battery technology. This is where CMC’s role in the anode becomes particularly significant. As a thickening and anti-settling agent, CMC improves the anode’s structural integrity and functionality, directly influencing the battery’s efficiency, safety, and cycle life. In the following sections, we will explore the unique properties of CMC and how its application in lithium-ion batteries represents a leap forward in energy storage technology.

The Role of CMC in Lithium-Ion Batteries

Carboxymethyl cellulose (CMC) plays a crucial role as a thickening and anti-settling agent in the anode manufacturing process for lithium-ion batteries. Its unique properties make it ideally suited for this application.

CMC’s Role in Anode Manufacturing:

- The anode slurry, composed of active anode material (typically graphite), conductive additives, and a polymer binder, is prepared in a solvent.

- CMC is added to the anode slurry as a thickening agent, increasing the viscosity of the slurry.

- The increased viscosity prevents the solid particles in the slurry from settling, ensuring a homogeneous distribution of the components.

- The thickened slurry is then coated onto a copper foil (current collector) and dried, forming the anode electrode.

Properties of CMC that Make it Ideal

a. Water Solubility and Thickening Ability:

- CMC is a water-soluble polymer, making it suitable for use in aqueous slurry systems.When dissolved in water, CMC molecules uncoil and become extended, increasing the viscosity of the solution.This thickening property allows CMC to effectively prevent settling of the solid particles in the anode slurry.

- In addition to its thickening ability, CMC acts as a binder, helping to hold the active anode material and conductive additives together.The carboxyl groups (-COOH) present in CMC molecules interact with the anode material and copper foil, providing adhesion and mechanical stability to the electrode.

- CMC is chemically stable and does not react with the components of the anode slurry or the electrolyte in lithium-ion batteries.It is compatible with the operating conditions and temperatures encountered during battery manufacturing and use.

- CMC is a relatively inexpensive and widely available material, making it a cost-effective choice for large-scale battery production.It is derived from natural sources (cellulose), contributing to its eco-friendly and sustainable nature.

- The thickening and binding properties of CMC facilitate the coating and drying processes, ensuring uniform and defect-free anode electrode fabrication.

- The homogeneous distribution of components within the anode contributes to improved electrochemical performance and cycle life of the battery.

In summary, CMC plays a vital role as a thickening and anti-settling agent in the anode manufacturing process for lithium-ion batteries. Its water solubility, thickening ability, binding capability, stability, cost-effectiveness, and processability make it an ideal choice for this application, contributing to the efficient and consistent production of high-quality anode electrodes.

Benefits of CMC in Battery Performance

The use of carboxymethyl cellulose (CMC) in lithium-ion batteries offers several benefits that contribute to improved stability, longevity, efficiency, and safety of the battery system. Here’s how CMC enhances battery performance:

- Improved Cycle Life and Stability:

- CMC acts as a binder, helping to maintain the structural integrity of the anode electrode during repeated charge and discharge cycles.

- The strong adhesion between the active anode material, conductive additives, and the copper current collector prevents the anode from degrading or delaminating over time.

- This mitigates the risk of anode cracking, which can lead to capacity fade and internal short circuits, ultimately extending the overall cycle life and stability of the battery.

- Enhanced Electrode Integrity:

- The thickening properties of CMC ensure a uniform distribution of the anode slurry components during the electrode manufacturing process.

- This homogeneous distribution results in a more consistent and robust anode structure, reducing the likelihood of defects or weak points.

- The improved electrode integrity translates to better long-term performance and reduced capacity degradation, contributing to the longevity of the battery.

- Improved Thermal Stability and Safety:

- CMC is a thermally stable material and does not undergo significant degradation or gas generation at the operating temperatures of lithium-ion batteries.

- This thermal stability helps maintain the structural integrity of the anode electrode, preventing potential internal short circuits caused by electrode deformation or particle detachment at high temperatures.

- The enhanced thermal stability of the anode electrode contributes to improved battery safety, reducing the risk of thermal runaway events.

- Efficient Lithium-Ion Transport:

- The homogeneous distribution of the anode components, facilitated by CMC, promotes efficient lithium-ion transport during charge and discharge cycles.

- This improved ionic conductivity within the anode electrode can lead to better rate capabilities and higher energy efficiency, as lithium ions can move more freely within the electrode structure.

- Reduced Internal Resistance:

- The binding properties of CMC ensure good electrical contact between the active anode material, conductive additives, and the current collector.

- This minimizes the internal resistance within the anode electrode, reducing energy losses and improving the overall efficiency of the battery.

- Cost-Effectiveness and Environmental Sustainability:

- CMC is a relatively inexpensive and readily available material, making it a cost-effective choice for large-scale battery production.

- Being derived from natural sources (cellulose), CMC contributes to the environmental sustainability of lithium-ion battery manufacturing processes.

By enhancing the structural integrity, thermal stability, ionic conductivity, and electrical contact within the anode electrode, CMC plays a crucial role in improving the overall performance, longevity, efficiency, and safety of lithium-ion batteries. Its unique properties make it an invaluable component in the battery manufacturing process, contributing to the development of high-performance and reliable energy storage systems.

Manufacturing Process of CMC

The manufacturing process of carboxymethyl cellulose (CMC) involves several steps to ensure high quality and consistency while adhering to environmental considerations. Here’s a brief outline of the CMC production process:

- Raw Material Preparation:

- The primary raw material for CMC production is cellulose, which is typically obtained from plant sources such as wood pulp, cotton linters, or other cellulosic materials.

- The cellulose is purified and treated to remove impurities and increase its reactivity.

- Alkali Treatment:

- The purified cellulose is treated with an alkaline solution, typically sodium hydroxide (NaOH), to swell and activate the cellulose fibers.

- This step is crucial for increasing the accessibility of the cellulose hydroxyl groups for subsequent etherification.

- Etherification (Carboxymethylation):

- The alkali-treated cellulose is reacted with a carboxymethylating agent, such as sodium monochloroacetate or sodium chloroacetic acid, under controlled temperature and pH conditions.

- This step introduces carboxymethyl groups (-CH2COONa) onto the cellulose backbone, converting it into CMC.

- Purification and Drying:

- After the etherification reaction, the CMC product is purified to remove unreacted reagents, by-products, and other impurities.

- This typically involves washing, neutralization, and filtration steps.

- The purified CMC is then dried, often using spray drying or drum drying techniques, to obtain a free-flowing powder.

- Quality Control and Consistency:

- Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the desired product specifications are met.

- Parameters such as degree of substitution (DS), viscosity, pH, and purity are closely monitored and adjusted as needed.

- Consistency in raw materials, reaction conditions, and processing steps is critical to achieving a uniform and reliable CMC product.

- Environmental Considerations:

- CMC production processes are designed to minimize environmental impact and promote sustainability.

- Efforts are made to optimize the use of raw materials, recover and reuse solvents and reagents, and treat waste streams before disposal.

- Efficient energy management and the use of renewable resources are also prioritized in modern CMC manufacturing facilities.

- Compliance with environmental regulations and certifications, such as ISO 14001, is essential for responsible CMC production.

The manufacturing process of CMC is carefully controlled and monitored to ensure consistent quality, purity, and performance of the final product. Environmental considerations are integrated into the process to minimize its ecological footprint and promote sustainable practices within the industry.

CMC’s Role in Innovations in Battery Technology

Carboxymethyl cellulose (CMC) has played a significant role in facilitating recent advancements in lithium-ion battery technology, and its importance is expected to continue as battery innovations progress. Here’s a discussion on CMC’s role in recent advancements and future trends in battery technology:

- Recent Advancements Facilitated by CMC:

- Silicon Anodes: CMC has been instrumental in the development of silicon-based anodes, which offer higher capacity and energy density compared to traditional graphite anodes. CMC’s binding properties help mitigate the volume expansion issues associated with silicon, improving cycle life and stability.

- High-Energy-Density Cathodes: The use of CMC as a binder in high-energy-density cathode materials, such as nickel-rich layered oxides (NMC, NCA), has enabled improved electrode integrity and cycle stability, contributing to the development of high-performance batteries.

- Thin and Flexible Electrodes: CMC’s thickening and binding properties have allowed the production of thin and flexible electrodes, enabling the development of lightweight and compact battery designs for applications like wearable electronics and flexible devices.

- Aqueous Processing: The water solubility of CMC has facilitated the adoption of aqueous processing techniques for electrode manufacturing, reducing the environmental impact and costs associated with organic solvent-based processes.

- Future Trends in Battery Technology and CMC’s Role:

- Solid-State Batteries: Solid-state batteries are a promising next-generation technology, and CMC may play a role as a binder or gelling agent in the solid electrolyte or electrode structures, contributing to improved interfacial stability and ionic conductivity.

- Multivalent Ion Batteries: Multivalent ion batteries, such as magnesium-ion or aluminum-ion batteries, are being explored as alternatives to lithium-ion batteries. CMC’s compatibility with different electrolyte systems and its binding properties could be leveraged in the development of these emerging battery technologies.

- High-Voltage Cathodes: As research continues on high-voltage cathode materials (e.g., nickel-rich NMC, lithium-rich oxides) for improved energy density, CMC’s role in maintaining structural integrity and mitigating degradation mechanisms will become increasingly important.

- Advanced Electrode Architectures: The development of advanced electrode architectures, such as 3D porous structures or composite electrodes, may benefit from CMC’s thickening and binding properties, enabling uniform coating and adhesion of active materials on complex geometries.

- Sustainability and Eco-Friendliness: CMC’s natural origin and biodegradability align well with the growing emphasis on sustainable and eco-friendly battery manufacturing processes. Its use could contribute to the development of greener battery technologies.

While the specific applications and roles of CMC in future battery technologies may evolve, its versatile properties as a thickening agent, binder, and stabilizer make it a valuable component in the ongoing innovations in lithium-ion and beyond-lithium-ion battery systems. As researchers continue to push the boundaries of energy density, cycle life, and safety, CMC’s contributions are likely to remain significant in enabling the development of advanced and high-performance battery technologies.

Case Studies: Real-world Applications

Carboxymethyl cellulose (CMC) has been widely used in the manufacturing of lithium-ion batteries for various real-world applications, owing to its unique properties and benefits. Here are some case studies that highlight the role of CMC in different applications:

- Electric Vehicles (EVs):

- Tesla’s lithium-ion battery packs used in their electric vehicles, such as the Model S, Model X, and Model 3, incorporate CMC as a binder and thickening agent in the anode electrodes.

- CMC’s ability to improve cycle life, structural integrity, and thermal stability of the anode contributes to the long-range and durability of Tesla’s EV batteries.

- The use of CMC has also enabled the production of high-energy-density anodes, which is crucial for achieving longer driving ranges in EVs.

- Consumer Electronics:

- Apple’s lithium-ion batteries used in various products, including iPhones, iPads, and MacBooks, utilize CMC in the anode electrode formulations.

- The binding properties of CMC help maintain the integrity of the anode during repeated charge/discharge cycles, contributing to the long-lasting battery life of Apple’s devices.

- CMC’s thermal stability also enhances the safety of these consumer electronics batteries, reducing the risk of thermal runaway events.

- Energy Storage Systems:

- LG Chem, a major battery manufacturer, employs CMC as a binder in their lithium-ion battery cells used for residential and commercial energy storage systems.

- The use of CMC in these batteries helps improve cycle life and efficiency, which is crucial for grid-scale energy storage applications.

- The binding properties of CMC contribute to the high-power and high-energy capabilities of LG Chem’s batteries, enabling efficient energy storage and delivery.

- Power Tools:

- DeWalt, a leading power tool manufacturer, uses lithium-ion battery packs with CMC-based anodes in their cordless power tool products.

- The improved electrode integrity and stability provided by CMC allow these battery packs to withstand the high-power demands and vibrations associated with power tool applications.

- The use of CMC has enabled DeWalt to develop compact and high-performance battery packs for their cordless tools, enhancing user experience and productivity.

- Medical Devices:

- Lithium-ion batteries used in implantable medical devices, such as pacemakers and defibrillators, often incorporate CMC in the anode formulations.

- The thermal stability and safety aspects offered by CMC are crucial in these medical applications, where battery failure could have severe consequences.

- CMC’s binding properties also contribute to the long-term reliability and consistent performance of these medical device batteries.

Across these diverse applications, the use of CMC in lithium-ion batteries has enabled improvements in cycle life, energy density, thermal stability, safety, and overall performance. CMC’s unique properties have played a vital role in advancing battery technology and meeting the demanding requirements of various industries, from consumer electronics to electric vehicles and energy storage systems.

Challenges and Future Prospects

While carboxymethyl cellulose (CMC) has proven to be a valuable component in lithium-ion battery manufacturing, there are still some challenges and areas for improvement that researchers and industry professionals are addressing. Additionally, future research directions and potential developments in CMC’s role in battery technology are being explored. Here are some key points:

- Current Challenges:

- Thermal Stability Limitations: While CMC exhibits good thermal stability compared to many other binders, its stability can still be compromised at higher temperatures (above 200°C). This limitation becomes more pronounced in high-voltage battery systems or under abuse conditions.

- Ion Conductivity: The insulating nature of CMC can hinder efficient ion transport within the electrode, potentially limiting rate capabilities and power density.

- Swelling and Dissolution: CMC can swell or partially dissolve in certain electrolyte systems, leading to potential electrode deformation and performance degradation over time.

- Compatibility with New Electrode Materials: As researchers explore new anode and cathode materials with different chemistries and structures, ensuring CMC’s compatibility and optimizing its performance in these systems remain challenges.

- Future Research Directions and Potential Improvements:

- Thermal Stabilization Strategies: Researchers are exploring techniques to improve the thermal stability of CMC, such as chemical modifications, crosslinking, or the incorporation of inorganic fillers. These approaches aim to extend CMC’s effective temperature range and enhance its performance in high-temperature or abuse conditions.

- Conductive Binder Systems: Combining CMC with conductive additives or developing intrinsically conductive CMC derivatives could improve ion conductivity and rate capabilities of electrodes, enabling higher power densities.

- Electrolyte Compatibility: Tailoring the chemical structure of CMC or modifying its properties to improve compatibility with different electrolyte systems, including novel electrolytes for beyond-lithium-ion batteries, is an area of active research.

- Nanocomposite and Hybrid Binders: Incorporating CMC into nanocomposite or hybrid binder systems with other polymers or inorganic materials could synergistically combine the advantages of different binders, potentially enhancing overall electrode performance.

- Sustainable and Bio-derived CMC: Exploring the use of more sustainable and bio-derived sources for CMC production, such as agricultural waste or bacterial cellulose, could contribute to the overall environmental friendliness of battery manufacturing processes.

While CMC has already made significant contributions to the advancement of lithium-ion battery technology, ongoing research efforts aim to address its limitations and further enhance its performance. By improving thermal stability, ion conductivity, and compatibility with new electrode materials and electrolyte systems, CMC can continue to play a vital role in the development of next-generation battery technologies with higher energy densities, longer cycle lives, and improved safety profiles.

Conclusion

Carboxymethyl cellulose (CMC) has proven to be an indispensable component in the advancement of lithium-ion battery technology. Its unique properties as a thickening agent, binder, and stabilizer have played a crucial role in enabling the development of high-performance, efficient, and safe lithium-ion batteries across various applications.

CMC’s contributions to lithium-ion battery technology are multifaceted. Its thickening ability ensures a homogeneous distribution of anode slurry components, preventing particle settling and enabling uniform electrode coatings. Additionally, CMC’s binding properties maintain the structural integrity of the anode, mitigating degradation and delamination during repeated charge-discharge cycles, thereby enhancing cycle life and overall battery longevity.

Moreover, CMC’s thermal stability and compatibility with battery materials contribute to improved safety profiles, reducing the risk of internal short circuits and thermal runaway events. Its water solubility has facilitated the adoption of environmentally friendly and cost-effective aqueous processing techniques in electrode manufacturing.

The widespread adoption of CMC in various applications, including electric vehicles, consumer electronics, energy storage systems, power tools, and medical devices, highlights its versatility and significance in meeting the diverse requirements of these industries. From enabling long-range capabilities in EVs to ensuring reliable performance in implantable medical devices, CMC has played a pivotal role in pushing the boundaries of battery technology.

However, despite its numerous advantages, ongoing research and development efforts are crucial to address the current challenges associated with CMC’s use in lithium-ion batteries. These challenges include thermal stability limitations, ion conductivity constraints, swelling and dissolution concerns, and compatibility with emerging electrode materials and electrolyte systems.

Future research directions encompass thermal stabilization strategies, conductive binder systems, improved electrolyte compatibility, nanocomposite and hybrid binders, and the exploration of sustainable and bio-derived sources for CMC production. These efforts aim to further enhance CMC’s performance, enabling the development of next-generation battery technologies with higher energy densities, longer cycle lives, and improved safety profiles.

As the demand for advanced energy storage solutions continues to grow, the importance of CMC in lithium-ion battery technology remains paramount. By addressing current challenges and capitalizing on future research opportunities, CMC can continue to play a vital role in driving the evolution of battery technology, contributing to a more sustainable and energy-efficient future.