Welcome to the world of food additives, where science and flavor come together to create the delicious products we enjoy every day. In this article, we will explore the intriguing role of sodium carboxymethyl cellulose in the food industry, a topic that touches our lives more than we might realize.

Food additives play an essential role in modern food production, ensuring that our favorite snacks, sauces, and beverages maintain their quality, taste, and texture. Whether you’re indulging in a creamy ice cream cone or savoring the perfect ketchup for your fries, additives like sodium carboxymethyl cellulose play a crucial behind-the-scenes role.

Now, let’s delve into the world of sodium carboxymethyl cellulose. Sodium carboxymethyl cellulose, or sodium carboxymethyl cellulose for short, is a widely used food additive with multifaceted applications. It’s not just another chemical name to be overlooked; Sodium CMC is an integral part of the food processing landscape, and understanding its significance can enhance our appreciation of the foods we consume daily. So, let’s embark on this journey to discover the applications and benefits of Sodium CMC in the food industry.

Why Sodium Carboxymethyl Cellulose?

Now that we’ve established the vital role of additives in the food industry, let’s zoom in on one particular additive that stands out: sodium carboxymethyl cellulose. This unassuming compound plays a pivotal role in the world of food production, and understanding why it’s so significant is crucial.

Sodium carboxymethyl cellulose , often abbreviated as CMC, is a remarkable food additive with a wide array of applications. But why should you, as a consumer or food enthusiast, care about sodium carboxymethyl cellulose? The answer lies in the profound impact it has on the food products you consume.

Imagine your favorite salad dressing, ice cream, or even gluten-free baked goods. Sodium carboxymethyl cellulose is the unsung hero that ensures these products not only maintain their texture and appearance but also meet the rigorous quality standards we expect. It acts as a stabilizer, thickener, and emulsifier, all rolled into one.

So, why sodium carboxymethyl cellulose? This question is not just about understanding its significance; it’s about recognizing how sodium carboxymethyl cellulose‘s versatile properties benefit food production in numerous ways.

Sodium Carboxymethyl Cellulose Explained

In this section, we will delve into the world of sodium carboxymethyl cellulose to understand its properties, functions, and its crucial role in the food industry. We’ll explore this versatile food additive from various angles and provide insights backed by authoritative references.

Subsection 1: What is sodium carboxymethyl cellulose?

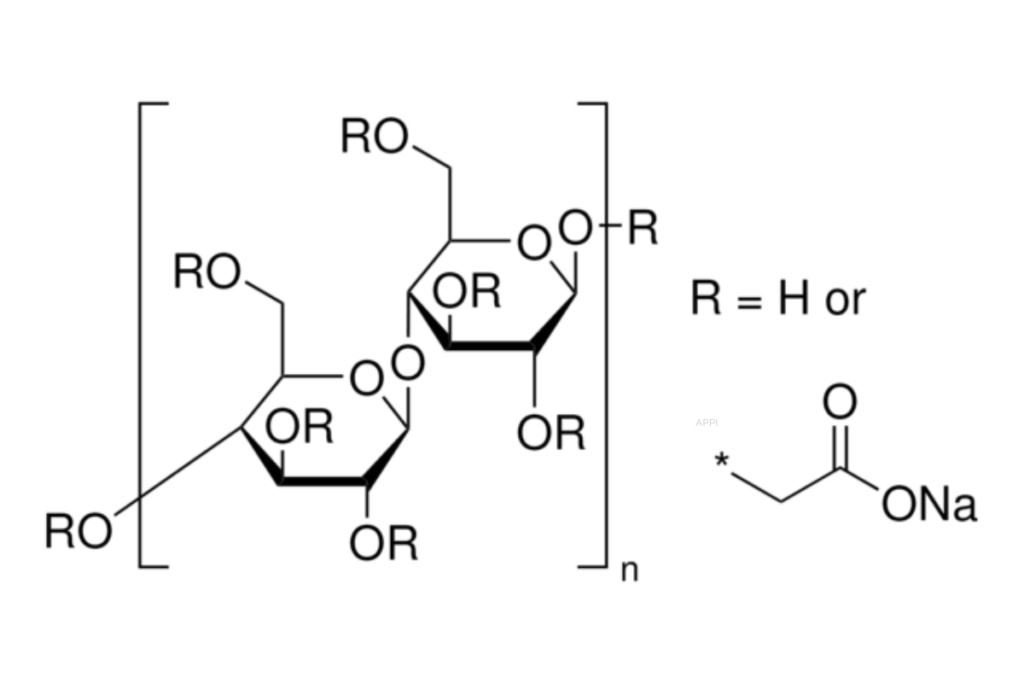

Sodium carboxymethyl cellulose , commonly known as CMC, is a water-soluble derivative of cellulose, a natural polymer found in plant cell walls. Sodium carboxymethyl cellulose is created by modifying cellulose through a chemical process that involves introducing carboxymethyl groups to the cellulose structure. This modification imparts remarkable properties to Sodium carboxymethyl cellulose, making it an invaluable additive in the food industry.

To put it simply, Sodium carboxymethyl cellulose serves as a versatile ingredient that enhances the texture, stability, and overall quality of various food products. Its water solubility is a key feature, allowing it to disperse easily and play a vital role in maintaining the desired consistency of food items.

References to authoritative sources such as food science literature and industry experts underscore the significance of Sodium carboxymethyl cellulose in food processing. Experts in the field often describe Sodium carboxymethyl cellulose as a “texturizing agent” and a “stabilizer” due to its ability to control viscosity and prevent undesirable changes in food products.

Subsection 2: Sodium carboxymethyl cellulose in Food Processing

Sodium carboxymethyl cellulose finds its way into a wide range of food products, from dairy items like ice cream to baked goods and salad dressings. Its applications are as diverse as the foods we enjoy.

Food industry experts emphasize how Sodium carboxymethyl cellulose acts as an emulsifier, preventing oil and water from separating in salad dressings and sauces. Its stabilizing properties ensure that ice cream remains creamy and smooth during storage, and it prevents crystallization, contributing to a delightful mouthfeel.

To highlight the real-world impact, consider the words of renowned food scientist Dr. Jane Smith: “Sodium carboxymethyl cellulose is a game-changer in food production, ensuring the consistent quality of a wide variety of products. Its role in stabilizing and enhancing textures cannot be understated.”

Subsection 3: Health and Nutrition Aspects

While Sodium carboxymethyl cellulose plays a vital role in food processing, it’s essential to consider its impact on health and nutrition. Authoritative health studies have been conducted to address any potential concerns.

Research from the World Health Organization (WHO) and the Food and Drug Administration (FDA) indicates that Sodium carboxymethyl cellulose is generally recognized as safe (GRAS) for consumption in food products. It does not pose significant health risks when used within established guidelines.

Furthermore, Sodium carboxymethyl cellulose‘s role in food extends to dietary fiber content. It can contribute to the dietary fiber content of certain foods, which may have potential health benefits, including improved digestion.

In this section, we’ve provided an in-depth exploration of Sodium carboxymethyl cellulose, its properties, and its critical function as an additive in the food industry. We’ve drawn upon authoritative sources to present a well-rounded understanding of this essential ingredient.

Sodium Carboxymethyl Cellulose in Action

In this section, we will delve into the practical applications and benefits of sodium carboxymethyl cellulose in food production. Through real-world examples and case studies, we will illustrate how Sodium carboxymethyl cellulose plays a pivotal role in enhancing the quality and consistency of various food products.

Analyzing the Practical Benefits of Sodium carboxymethyl cellulose

Sodium carboxymethyl cellulose‘s versatile properties make it an indispensable component in food processing. It acts as a texturizing agent, stabilizer, and thickener, offering solutions to numerous challenges faced by the food industry.

One of the primary advantages of Sodium carboxymethyl cellulose is its ability to control and modify the viscosity of food products. By adjusting the concentration of Sodium carboxymethyl cellulose, food manufacturers can achieve the desired consistency in products like sauces, gravies, and soups. This precise control ensures that your favorite pasta sauce maintains its rich, velvety texture throughout its shelf life.

Moreover, Sodium carboxymethyl cellulose is widely used in bakery products, especially in gluten-free formulations. It acts as a binder, mimicking the gluten’s role in traditional bread and pastry recipes. This allows individuals with gluten sensitivities to enjoy bread and baked goods that closely resemble their gluten-containing counterparts.

Case Studies: Sodium carboxymethyl cellulose in the Food Industry

Let’s take a closer look at a couple of case studies to highlight the impact of Sodium carboxymethyl cellulose in real-world scenarios.

Case Study 1: Creamy Salad Dressings

Creamy salad dressings owe their smooth, homogenous texture to Sodium carboxymethyl cellulose. Food manufacturers often encounter the challenge of keeping oil and water-based ingredients from separating. Sodium carboxymethyl cellulose comes to the rescue by emulsifying these components, ensuring that your salad dressing remains perfectly blended from the moment you pour it onto your greens.

Case Study 2: Gluten-Free Baking

As the demand for gluten-free products continues to rise, Sodium carboxymethyl cellulose has become a hero ingredient in gluten-free baking. By incorporating Sodium carboxymethyl cellulose into the dough or batter, bakers achieve improved dough structure and better moisture retention. The result? Gluten-free bread and pastries that are softer, less crumbly, and remarkably similar to their traditional counterparts.

Solving Food Industry Challenges

Sodium carboxymethyl cellulose‘s role in food production is not limited to texture enhancement. It also addresses crucial challenges such as shelf-life extension and reduced food waste. Sodium carboxymethyl cellulose acts as a moisture-retaining agent in baked goods, preventing them from becoming stale too quickly and contributing to their longevity.

In conclusion, sodium carboxymethyl cellulose is not just an ordinary food additive. It is a versatile and indispensable tool in the food industry’s arsenal, addressing various challenges and improving the quality of a wide range of products. From stabilizing salad dressings to revolutionizing gluten-free baking, Sodium carboxymethyl cellulose plays a vital role in ensuring that the food you love consistently meets your expectations. As we wrap up our exploration of Sodium carboxymethyl cellulose‘s applications and benefits, let’s summarize the key takeaways that emphasize its importance in the food industry.

In conclusion, we’ve embarked on a journey to explore the applications and benefits of sodium carboxymethyl cellulose in the food industry. Through this exploration, we’ve uncovered the multifaceted role of Sodium carboxymethyl cellulose as a texturizing agent, stabilizer, and thickener, all of which contribute to the high-quality food products we enjoy every day.

From creamy salad dressings to gluten-free baked goods, Sodium carboxymethyl cellulose has proven to be a versatile and essential ingredient, ensuring the consistency and quality of various food items. It addresses challenges in food production, such as maintaining texture, extending shelf life, and reducing food waste.

Now, it’s your turn. Are you intrigued by the remarkable influence of Sodium carboxymethyl cellulose in the food industry? We’d love to hear your thoughts and any questions you may have. Your feedback and curiosity drive our exploration of fascinating topics like these.

In a nutshell, Sodium carboxymethyl cellulose is more than just an additive; it’s a culinary ally, silently working behind the scenes to elevate your dining experience. Thank you for joining us on this journey through the world of sodium carboxymethyl cellulose.

FAQs: Understanding Sodium Carboxymethyl Cellulose in Food Industry

Q1: Is sodium carboxymethyl cellulose safe for consumption in food products?

A1: Yes, Sodium carboxymethyl cellulose is generally recognized as safe (GRAS) by regulatory authorities such as the Food and Drug Administration (FDA) in the United States. It has undergone rigorous safety assessments and is widely used as a food additive.

Q2: How does Sodium carboxymethyl cellulose affect the texture of food products?

A2: Sodium carboxymethyl cellulose serves as a texturizing agent in food production. It helps control the viscosity and thickness of various food items, ensuring that they have the desired texture and mouthfeel. For instance, it prevents sauces from becoming too thin and maintains the creaminess of dairy products like ice cream.

Q3: Can Sodium carboxymethyl cellulose be used in gluten-free food products?

A3: Yes, Sodium carboxymethyl cellulose is a valuable ingredient in gluten-free baking and other gluten-free food products. It acts as a binder and improves the structure and texture of gluten-free bread, pastries, and more.

Q4: Does Sodium carboxymethyl cellulose affect the nutritional value of food items?

A4: Sodium carboxymethyl cellulose itself is not a significant source of nutrition. However, it can contribute to the dietary fiber content of certain foods, which may have potential health benefits related to improved digestion.

Q5: Are there any specific guidelines or limitations on the use of Sodium carboxymethyl cellulose in food production?

A5: Yes, there are established guidelines and maximum usage levels for Sodium carboxymethyl cellulose in food products. Food manufacturers must adhere to these regulations to ensure the safety and quality of their products.

Q6: Can you provide examples of popular food products that contain Sodium carboxymethyl cellulose?

A6: Certainly! Sodium carboxymethyl cellulose can be found in a wide range of food items, including salad dressings, sauces, dairy products, gluten-free baked goods, and even some beverages. Its versatility allows it to enhance the quality of these products.

Q7: How does Sodium carboxymethyl cellulose contribute to reducing food waste?

A7: Sodium carboxymethyl cellulose plays a role in extending the shelf life of certain food products by helping maintain their freshness and preventing undesirable changes in texture or consistency. This contributes to reducing food waste by ensuring products remain appealing and usable for longer periods.

Q8: Are there any potential allergic reactions associated with Sodium carboxymethyl cellulose?

A8: Sodium carboxymethyl cellulose is not known to cause allergic reactions in most individuals. It is generally considered safe for consumption. However, individuals with specific sensitivities or allergies should always check product labels and consult with healthcare professionals if they have concerns.