The realm of industrial additives stands as a testament to the advancements in modern technology, with these substances playing pivotal roles in enhancing the functionality and quality of products across various sectors. Among these key additives is sodium carboxymethyl cellulose (CMC) powder, a compound that has revolutionized multiple industries with its multifaceted applications. Known for its remarkable properties, sodium CMC powder serves as a cornerstone in the development of numerous products, ranging from everyday household items to specialized industrial materials. Its unique chemical composition and versatile nature make it an indispensable component in many manufacturing processes. This introduction delves into the essence of sodium carboxymethyl cellulose powder, shedding light on its integral role as a transformative industrial additive.

The utilization of sodium CMC powder spans a wide array of industries, each benefiting from its distinct characteristics that cater to specific requirements. From the pharmaceutical and food production sectors to the textile industry, sodium CMC powder stands out for its efficacy in improving product consistency, stability, and overall quality. This article aims to explore the numerous industrial applications of sodium carboxymethyl cellulose powder, its advantageous properties, and the future prospects of this versatile additive in driving industrial innovation and efficiency.

What is Sodium Carboxymethyl Cellulose Powder?

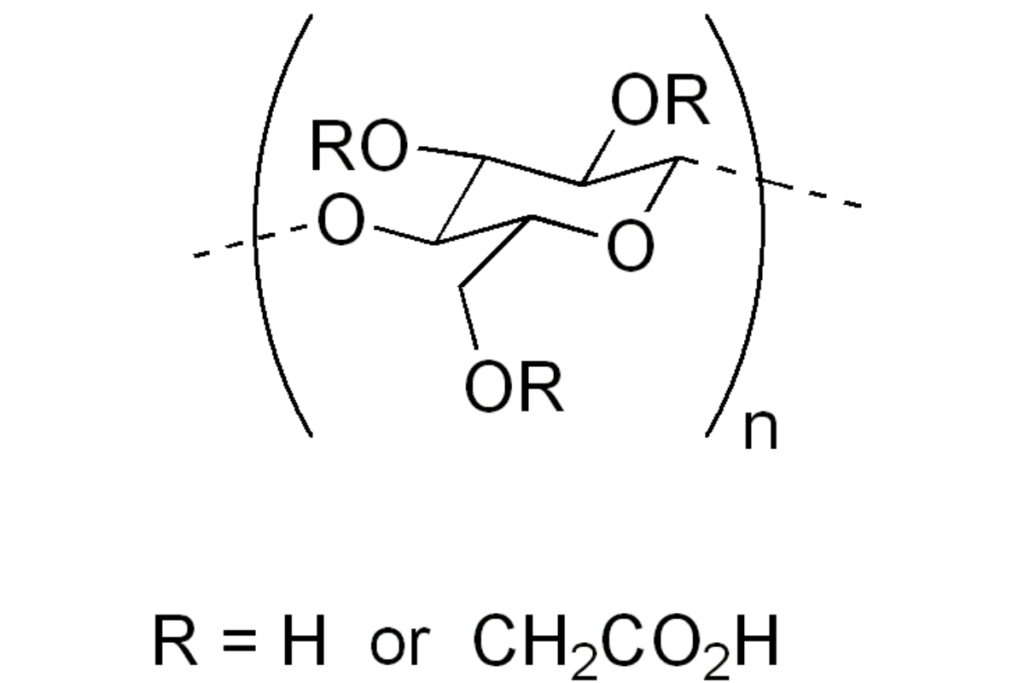

Sodium carboxymethyl cellulose powder, commonly referred to as sodium CMC powder, is a chemically modified derivative of cellulose. Characterized by its white to off-white appearance, this powder is distinguished by its unique chemical composition that includes carboxymethyl groups (-CH2-COOH) bound to the polysaccharide chains of cellulose. This modification endows the compound with hydrophilic properties, making it highly absorbent and soluble in water.

The production of sodium CMC powder involves a process known as etherification, wherein cellulose derived from natural sources, such as wood pulp or cotton lint, undergoes a chemical reaction with chloroacetic acid. This process not only alters the physical and chemical properties of cellulose but also transforms it into a more versatile and functional product. The resulting sodium CMC powder exhibits a range of viscosities and degrees of substitution, which can be tailored according to specific industrial needs.

Sodium CMC powder is highly valued in various industries for its ability to act as a thickening agent, stabilizer, and emulsifier. Its unique attributes such as non-toxicity, biodegradability, and its ability to form films make it a preferred choice in numerous applications. From thickening agents in food products to stabilizers in pharmaceuticals, and as a binding agent in cosmetic formulations, the diverse uses of sodium carboxymethyl cellulose powder highlight its indispensable role in modern industrial practices. This section will further delve into the versatile nature of sodium CMC powder, exploring its multifunctional applications and the process behind its transformation from natural cellulose to an all-encompassing industrial additive.

Key Industrial Applications of Sodium Carboxymethyl Cellulose Powder

Sodium carboxymethyl cellulose (CMC) powder is a versatile additive used across a wide spectrum of industries due to its unique properties. Here are some of the key areas where sodium CMC powder plays a pivotal role:

Pharmaceutical Industry: In pharmaceuticals, sodium CMC powder is extensively used as a binder, thickener, and stabilizer. It enhances the texture and consistency of tablets and ensures controlled release of medication. It’s also used in oral suspensions and gels, contributing to the desired viscosity and mouthfeel.

Food Production: In the food industry, sodium CMC powder acts as an emulsifier and stabilizer in products like ice cream, baked goods, and dairy products. It helps in maintaining the homogeneity of food items, prevents ice crystal formation, and improves the mouthfeel of low-fat foods.

Textile Industry: Sodium CMC powder is used in the textile industry as a sizing agent and fabric stabilizer. It provides strength to yarns during weaving and reduces breakage, thus improving the quality of the final textile product.

Cosmetics and Personal Care: In the cosmetics industry, sodium CMC powder is valued for its thickening properties. It is found in a variety of products, such as toothpaste, shampoos, and skincare items, where it aids in achieving the desired consistency and smooth application.

Paper Production: In paper manufacturing, sodium CMC powder is used to improve sheet formation, increase paper strength, and enhance the retention of dyes and inks. It contributes to the durability and quality of the paper.

Oil and Gas Industry: Sodium CMC powder serves as a viscosity modifier and water retention agent in drilling muds used in oil and gas exploration. It helps in stabilizing the drilling fluid and facilitates efficient drilling operations.

Others: Other applications include its use in adhesives, detergents, and water-based paints, where it acts as a thickening and stabilizing agent.

Each of these applications leverages the unique characteristics of sodium CMC powder, such as its ability to modify viscosity, stabilize emulsions, and bind ingredients. The specific roles and benefits of sodium CMC powder in these industries underscore its versatility and the critical part it plays in enhancing the quality and efficiency of various products.

Advantages of Sodium Carboxymethyl Cellulose Powder in Industry

Sodium carboxymethyl cellulose (CMC) powder offers several unique advantages that make it a highly valued additive in various industries. These benefits stem from its exceptional chemical properties and functional versatility.

Enhancing Product Consistency and Stability: One of the primary advantages of sodium CMC powder is its ability to improve the consistency and stability of products. In industries like food and pharmaceuticals, it acts as a thickener and stabilizer, ensuring that products maintain uniform texture and do not separate over time.

Improving Viscosity and Flow Properties: Sodium CMC powder is an effective viscosity modifier. It is used in products like sauces and dressings in the food industry, as well as in oil drilling fluids, to control flow properties. This makes processing easier and enhances the end-user experience.

Non-Toxic and Safe: Being non-toxic and hypoallergenic, sodium CMC powder is safe for use in consumer products, which is crucial in industries where product safety is a priority, such as in food, pharmaceuticals, and personal care products.

Compatibility with Various Ingredients: Sodium CMC powder is compatible with a wide range of other ingredients, which makes it a versatile choice for formulations that contain multiple components. This compatibility is beneficial in complex formulations found in pharmaceuticals and cosmetics.

Cost-Effective and Efficient: As an effective thickening agent, only small quantities of sodium CMC powder are needed to achieve desired results, making it a cost-effective option for manufacturers. Its efficiency in improving product quality and shelf-life further adds to its economic advantages.

Eco-Friendly and Sustainable: Derived from natural cellulose, sodium CMC powder is an environmentally friendly option. Its biodegradability and non-toxic nature make it a sustainable choice for industries looking to reduce their environmental impact.

Enhancing Consumer Experience: In consumer goods, such as food and personal care products, sodium CMC powder contributes to a more pleasing texture, consistency, and overall sensory experience, which is vital for consumer satisfaction and brand loyalty.

The utilization of sodium CMC powder in industrial applications is not just about improving the physical properties of products; it’s also about enhancing production efficiency, ensuring safety, and contributing to sustainability. These comprehensive benefits highlight why sodium CMC powder is a preferred choice in a wide range of industrial applications.

The Future of Sodium Carboxymethyl Cellulose Powder in Industry

The future of sodium carboxymethyl cellulose (CMC) powder in industrial applications appears to be marked by innovation and expanding uses. The versatility of this compound ensures its ongoing relevance in a variety of sectors, with potential for further development.

Emerging Trends in Application: Emerging trends indicate a broadening scope of applications for sodium CMC powder. Research is exploring its use in more advanced fields, like biotechnology and nanotechnology. These areas promise innovative uses, such as in drug delivery systems or as a component in nanocomposite materials.

Advancements in Manufacturing and Processing: Advancements in manufacturing processes are expected to enhance the quality and specificity of sodium CMC powder. This could lead to more refined grades of the compound, tailored for specialized industrial applications, thus expanding its utility.

Sustainability and Eco-Friendly Practices: As industries move towards more sustainable practices, the demand for eco-friendly additives like sodium CMC powder is likely to increase. Its biodegradable nature and derivation from natural sources position it as a favorable choice in environmentally conscious manufacturing processes.

Collaboration between Industry and Academia: The collaboration between industrial players and academic institutions is poised to drive innovation in the use of sodium CMC powder. Such partnerships are crucial for research and development, leading to new applications and improved formulations.

Focus on Health and Safety Standards: Ongoing developments in health and safety regulations will continue to influence the use of sodium CMC powder in industries such as food and pharmaceuticals. Compliance with these evolving standards is key to maintaining consumer trust and industry credibility.

Customization for Specific Industry Needs: Customized solutions using sodium CMC powder to meet specific industry needs are an emerging trend. This involves developing unique formulations of the compound to address particular challenges or requirements of different industrial sectors.

Enhanced Consumer Experience through Innovation: Finally, the drive to enhance consumer experience through innovative product formulations will continue to fuel the use of sodium CMC powder. Its role in improving product texture, stability, and usability will remain crucial in consumer-oriented industries.

In summary, the future of sodium CMC powder in industry is characterized by advancements in application, manufacturing, sustainability, and regulatory compliance. Its adaptability and eco-friendly nature will keep it at the forefront of industrial additives, meeting the dynamic demands of various sectors.

Choosing the Right Sodium Carboxymethyl Cellulose Powder for Your Industry

Selecting the right grade and quality of sodium carboxymethyl cellulose (CMC) powder is crucial for industrial applications. This section provides guidelines for industry professionals to make informed decisions.

Understanding Different Grades of Sodium CMC Powder:

- Different grades of sodium CMC powder are designed for specific applications. These grades vary in terms of viscosity, degree of substitution, and purity.

- It’s important to understand the specific requirements of your application to choose the appropriate grade. For instance, a high-viscosity grade might be ideal for food applications as a thickener, while a lower viscosity grade could be more suitable for paper production.

Quality Considerations:

- Quality of sodium CMC powder is paramount. Ensure that the powder meets industry standards and certifications, especially for applications in food and pharmaceuticals.

- Check for compliance with regulatory bodies like the FDA or EMA, depending on your region. This ensures that the sodium CMC powder is safe and suitable for use.

Supplier Reliability:

- Choose a reliable supplier with a good track record. This includes consistency in product quality, adherence to delivery schedules, and transparency in their manufacturing processes.

- Consider suppliers who provide technical support and can offer insights into the best practices for using their product.

Evaluating Cost-Effectiveness:

- While cost is a significant factor, it should not be the only criterion for selection. Evaluate the cost-effectiveness of the sodium CMC powder by considering its performance, yield, and the overall benefit it brings to your product or process.

Sample Testing:

- Before making a bulk purchase, conduct sample testing. This helps in assessing how the sodium CMC powder interacts with other components in your formulation and its impact on the final product.

Addressing Storage and Handling:

- Proper storage and handling of sodium CMC powder are crucial for maintaining its quality. Ensure that you have the right facilities and protocols in place.

Environmental and Health Aspects:

- For industries focused on sustainability, consider the environmental impact of the sodium CMC powder. Opt for products that are environmentally friendly and safe for consumers.

Customization Options:

- Some suppliers offer customization of sodium CMC powder to meet specific industry needs. Explore these options if standard grades do not perfectly align with your application requirements.

In conclusion, choosing the right sodium CMC powder involves a thorough understanding of its grades, quality, supplier reliability, cost-effectiveness, and compliance with industry standards. Proper selection ensures optimal performance in industrial applications, aligning with both product quality and safety guidelines.

In conclusion, sodium carboxymethyl cellulose (CMC) powder plays a pivotal role in enhancing various industrial applications. Its versatility and diverse functionalities make it an indispensable ingredient in sectors ranging from food production to pharmaceuticals and textiles. This article has highlighted the importance of understanding the unique properties of sodium CMC powder, its industrial applications, and the advantages it offers in terms of improving product quality and process efficiency.

Understanding the chemical composition, viscosity, and stabilizing properties of sodium CMC powder is key to leveraging its full potential. The insights provided into its future applications and ongoing research demonstrate the dynamic nature of this compound and its evolving role in industrial advancements. For industry professionals, selecting the appropriate grade and quality of sodium CMC powder is crucial for achieving desired outcomes in product development and manufacturing processes.

The continued relevance and importance of sodium CMC powder in advancing industrial technologies and processes are undeniable. As industries evolve and new challenges arise, sodium CMC powder remains a vital component in meeting these demands, offering solutions that enhance product quality, efficiency, and consumer satisfaction. Its role in industrial applications is expected to grow, further cementing its status as a preferred additive in various sectors.