Have you ever wondered what makes your toothpaste thick and your ice cream smooth? The answer lies in a common yet underrated ingredient – carboxymethyl cellulose (CMC). This versatile compound is hidden in plain sight, playing an integral role in numerous everyday products. From the food on your table to the hygiene products in your bathroom, CMC is a silent workhorse that ensures quality and consistency. Its presence across various industries underlines its importance, yet many consumers are unaware of the science and significance behind this powerful polymer. This article will unveil the mystery of CMC, revealing why this substance is worthy of your attention.

What is Carboxymethyl Cellulose?

Carboxymethyl cellulose (CMC), often found in the list of ingredients across a spectrum of products, is a water-soluble polymer derived from cellulose, the structural component of plants. As an anionic synthetic gum, CMC is unique in its ability to alter the flow of aqueous solutions. This thickening and stabilizing agent is a cellulose derivative where the cellulose backbone has been chemically modified to bear carboxymethyl groups, thus giving it the ‘carboxymethyl’ name.

The reason what is carboxymethyl cellulose matters to you extends far beyond the realms of chemistry and manufacturing. Understanding CMC is to understand the mechanics behind the products you use daily — how your sauces attain their perfect pour, how pills disintegrate in your system, or how cosmetics retain their moisture. CMC’s role is as subtle as it is significant, ensuring product stability, texture, and usability. It is a silent enabler, enhancing your daily experience without making its presence obvious. Knowing about CMC can inform your choices as a consumer, highlighting its role in product safety, efficacy, and quality.

Understanding Carboxymethyl Cellulose

The Chemistry Behind carboxymethyl cellulose

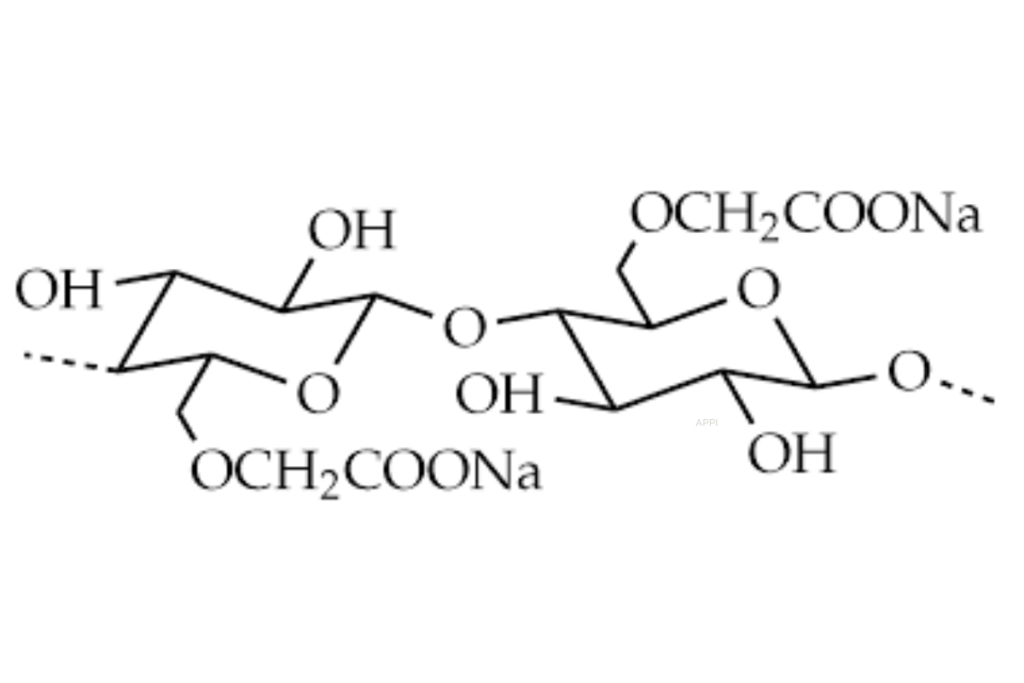

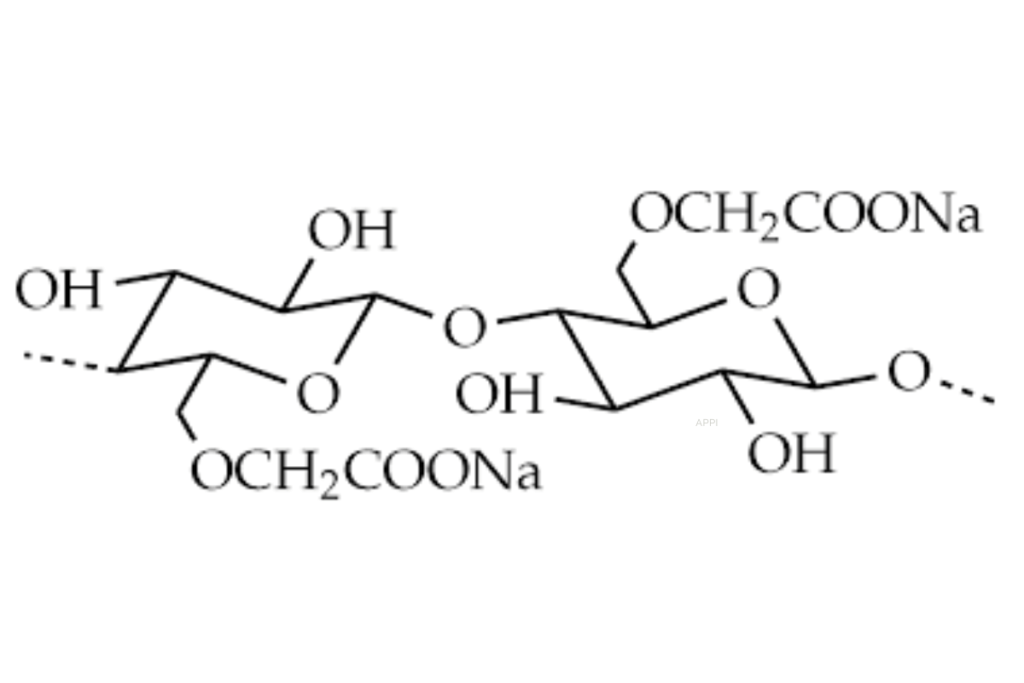

Carboxymethyl cellulose (CMC) is a cellulose derivative with the cellulose structure chemically altered to possess carboxymethyl groups (-CH2-COOH) attached to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone. This modification allows CMC to be more soluble in water than cellulose and gives it the ability to modify the viscosity of solutions, even at low concentrations. Dr. Alan Greene, a renowned chemist, states, “The carboxymethyl groups are the key to the unique properties of CMC, allowing it to act as a highly effective thickening agent, stabilizer, and water-retention compound.”

carboxymethyl cellulose in the Industrial World

CMC has a vast range of applications across various industries due to its non-toxic nature, biocompatibility, and versatile chemical structure. In the food industry, it’s used as a thickener and emulsifier. The pharmaceutical sector utilizes CMC as a binder and stabilizer in drug formulations, while the cosmetics industry incorporates it for its hydrating properties. A recent article in the Journal of Industrial Applications of Biopolymers highlights how “CMC’s film-forming capability makes it a suitable agent in coatings and adhesives, which are widely used in the textile and paper industries.”

Health and Safety Aspects of carboxymethyl cellulose

CMC is generally recognized as safe (GRAS) by the FDA when used within prescribed limits. Its non-toxicity has been a subject of study, and current research supports its safe use in many consumer products. Safety data sheets provided by manufacturers, such as Dow Chemical Company, offer guidance on handling CMC and state that “no special precautions are necessary if used correctly.” However, as with any substance, it is recommended to handle CMC with care, avoiding inhalation of powder and contact with eyes.

Through this detailed exploration of CMC’s chemical nature, industrial applications, and safety profile, one gains a comprehensive understanding of this multifaceted compound. These insights, backed by expert knowledge and literature, underscore the importance of CMC in modern-day manufacturing and its relevance to a safe, efficient production process.

The Significance of Carboxymethyl Cellulose

The implications of carboxymethyl cellulose (CMC) extend far beyond its basic applications, touching upon numerous facets of industrial and consumer products. Understanding the properties of CMC not only informs the choice of ingredients in production but also enhances the end-user experience by improving product stability, safety, and performance.

CMC’s role in the food industry is a prime example of its significance. As a thickener and stabilizer, it prevents the separation of ingredients, ensuring a consistent texture and taste. Dr. Lisa Hamilton, a food scientist, remarks, “CMC is integral to maintaining the quality that consumers expect from their food products. It’s the unsung hero in your salad dressings and ice creams.” This underscores the role of CMC in delivering the quality and reliability that consumers trust.

In the pharmaceutical realm, CMC’s binding properties are crucial. It acts as an excipient in tablets, facilitating the controlled release of medication within the body. According to pharmaceutical expert Dr. Mark Spencer, “The use of CMC in drug formulation is a game-changer, allowing for precise dosing and improved patient outcomes.”

Moreover, the implications of CMC in the cosmetic industry are profound. It serves as a humectant and texture enhancer in lotions and creams. Esteemed dermatologist Dr. Rachel Klein states, “Carboxymethyl cellulose has revolutionized product formulations by providing non-irritating, hydrating solutions that cater to sensitive skin types.”

Understanding the multifunctional nature of CMC allows manufacturers to innovate and improve their products. For instance, in the field of water-based paints and coatings, CMC acts as a rheology modifier, providing the desired thickness and flow properties for ease of application and an even finish.

The environmental aspect of CMC is also noteworthy. Being biodegradable and non-toxic, it is a preferred choice in environmentally friendly products and processes. Environmental scientist Dr. Omar Faruq comments, “CMC’s biocompatibility makes it a cornerstone for sustainable practices within industries looking to reduce their ecological footprint.”

In essence, carboxymethyl cellulose is more than just a compound; it’s a versatile ingredient that enhances product functionality across various sectors. Its understanding can lead to better, more informed choices in both product development and consumer habits, driving the market towards more sustainable and high-quality offerings.

In the realm of polymers, carboxymethyl cellulose (CMC) stands out for its unparalleled versatility and its application across a multitude of industries. From thickening your favorite desserts to stabilizing pharmaceuticals, and enhancing cosmetic formulations, CMC’s role is pivotal. Its chemical adaptability not only meets diverse industrial needs but also aligns with the push towards sustainable and safe product development.

The significance of CMC is rooted in its ability to solve practical problems, improve product lifespans, and ensure consumer safety. As we’ve explored its chemistry, applications, and health considerations, it’s clear that CMC is more than just an additive—it’s a testament to the innovation within material science.

We hope this exploration into the world of CMC has piqued your interest and broadened your understanding of how such a substance shapes your daily experiences. What applications of CMC have you encountered in your life? Share your thoughts and join the conversation about this fascinating compound.

To succinctly encapsulate the essence of our discussion: Carboxymethyl cellulose is an invisible yet indispensable architect of product integrity and efficiency.

Exploring Carboxymethyl Cellulose: Your Questions Answered

What exactly is carboxymethyl cellulose used for?

Carboxymethyl cellulose (CMC) serves a myriad of purposes due to its ability to thicken, stabilize, and retain moisture in products. It is widely used in the food industry to improve texture and in pharmaceuticals as a non-digestible thickener that facilitates drug delivery.

Is carboxymethyl cellulose safe for consumption?

CMC has been deemed safe for consumption by various health authorities, including the FDA. It is widely used in food products and is generally regarded as a non-toxic and non-allergenic substance.

How does carboxymethyl cellulose impact the environment?

Being derived from natural cellulose, CMC is biodegradable. Its environmental impact is minimal when compared to synthetic polymers, making it a preferred choice in green manufacturing practices.

Can carboxymethyl cellulose be used in gluten-free products?

Yes, CMC is gluten-free and can be used as a substitute for gluten in baked goods to add texture and moisture retention without triggering gluten-related health issues.

Does carboxymethyl cellulose have a taste?

CMC is tasteless and odorless, which is why it is so valuable in food products — it modifies texture without affecting flavor profiles.