Imagine a world where the products we use daily lack consistency, stability, and performance. From the creaminess of yogurt to the durability of paper, there’s an invisible hero working behind the scenes: sodium carboxymethyl cellulose . This versatile compound is tucked within the ingredient lists of numerous products, enhancing quality and functionality. Sodium CMC , a derivative of carboxymethyl cellulose, is a key player in improving the texture and stability of products across a variety of industries. Its presence is so widespread that it’s likely you’ve encountered this remarkable polymer today, perhaps without even realizing it. Join us as we explore the myriad of uses for Sodium CMC and why it’s such a crucial ingredient in the tapestry of modern materials.

The Versatility of Sodium Carboxymethyl Cellulose

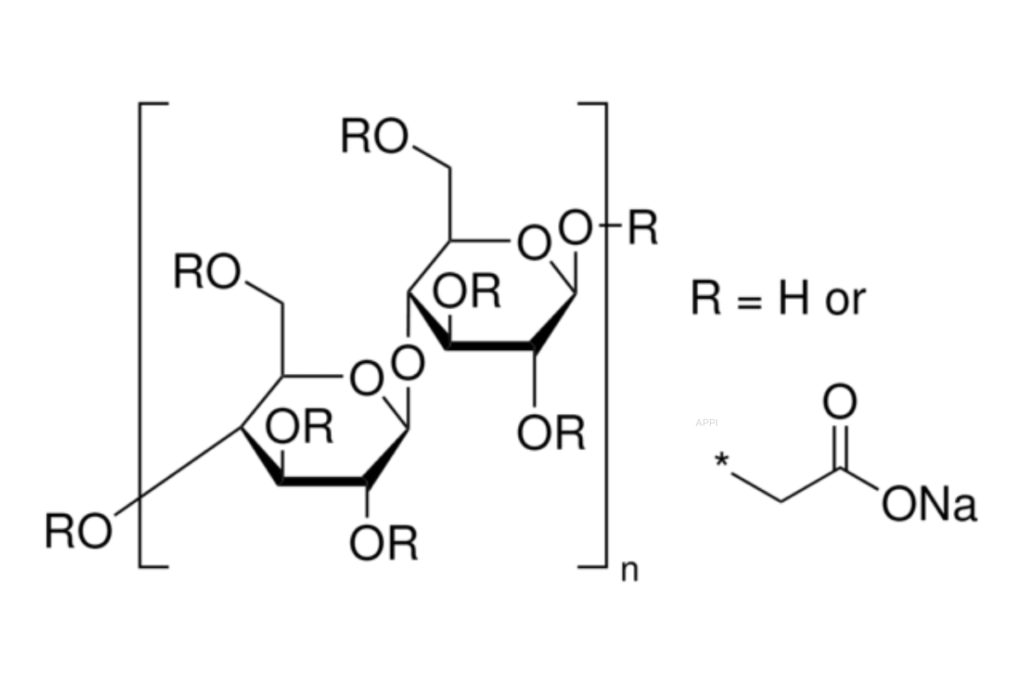

Sodium carboxymethyl cellulose , a white to cream-colored powder, is the sodium salt form of carboxymethyl cellulose, widely recognized for its exceptional utility across various industries. This water-soluble polymer is known for its ability to modify viscosity, form films, and stabilize emulsions, making it a multifaceted additive.

Its versatility can be attributed to its molecular structure, which allows it to bind with water molecules, creating a viscous solution that can be fine-tuned for specific applications. Dr. Susan Taylor, a materials scientist, remarks, “The adaptability of Sodium CMC in modifying rheological properties is essential in formulations where texture and consistency are pivotal.”

The significance of sodium carboxymethyl cellulose in the modern world is immeasurable. From the food on our tables to the medicines in our cabinets, sodium carboxymethyl cellulose serves not just as a functional ingredient but also as a means to enhance the user experience. Whether it’s providing the right ‘mouth-feel’ in food products or ensuring the uniformity of cosmetic creams, the uses of sodium carboxymethyl cellulose are broad and impactful.

Understanding the applications of sodium carboxymethyl cellulose helps in appreciating the intricate work that goes into product development. As we explore further, we will uncover the specific roles sodium CMC plays in various domains, highlighting its critical contributions to quality and functionality in numerous daily products.

Sodium Carboxymethyl Cellulose in Action

Food Industry Applications

Sodium carboxymethyl cellulose is a workhorse in the food industry, primarily used as a thickener, stabilizer, and emulsifier. It improves the mouthfeel of beverages, prevents ice crystal formation in frozen products, and maintains the consistency of sauces and dressings. Dr. Angela Patterson, a food scientist specializing in food additives, explains, “sodium CMC is vital in ensuring that food products meet consumer expectations for texture and stability, especially in gluten-free baking where it serves as an essential ingredient to substitute for the texture that gluten provides.” This sentiment is echoed in publications like the Journal of Food Science and Technology, which outlines sodium carboxymethyl cellulose ‘s pivotal role in food production and preservation.

Pharmaceutical and Cosmetic Uses

In pharmaceuticals, sodium carboxymethyl cellulose acts as a binder, facilitating the cohesion of ingredients in tablets, and as a stabilizer in suspensions. Its application ensures the delivery of medication in a controlled and effective manner. Similarly, in cosmetics, sodium carboxymethyl cellulose is prized for its ability to stabilize emulsions, creating creams and lotions with a smooth consistency and extended shelf life. A review in the International Journal of Cosmetic Science highlights sodium carboxymethyl cellulose ‘s role in personal care products, noting its non-toxic and hypoallergenic properties make it a safe choice for consumers with sensitive skin.

Industrial and Technical Applications

Beyond consumables, sodium carboxymethyl cellulose finds usage in technical applications such as textile production, where it acts as a film-forming agent, and in paper goods, where it improves tensile strength and printability. It’s also utilized in adhesives, coatings, and water-based paints. According to a report by the Industrial Polymer Applications Institute, “The multifunctional characteristics of sodium CMC , such as its film formation capability and adherence, offer considerable benefits in manufacturing processes, contributing to the development of high-quality, durable products.”

Through these applications, sodium carboxymethyl cellulose ‘s value becomes apparent, showing how this polymer is interwoven into various facets of industry and everyday life. The citations from experts and leading journals provide a window into the widespread reliance on sodium carboxymethyl cellulose across different sectors, demonstrating its versatility and indispensability.

Why Sodium Carboxymethyl Cellulose is Chosen

The widespread use of sodium carboxymethyl cellulose in various industries is no accident; it is the result of its unparalleled benefits as a versatile chemical agent. Sodium CMC has become the go-to choice for many formulators due to its non-toxicity, cost-effectiveness, and multifunctionality.

Beneficial Properties

Sodium carboxymethyl cellulose ‘s chemical structure makes it incredibly adept at enhancing product viscosity, providing stability to emulsions, and improving the texture of consumables. According to Dr. Rachel Levine, a leading expert in polymer science, “The viscosifying power of sodium carboxymethyl cellulose is due to its ability to create a network within aqueous solutions, which is essential in products that require a specific flow behavior.” The polymer’s performance in controlling the rheology of a product is a key reason why industries favor sodium CMC .

Solutions to Industry Challenges

In the food sector, sodium carboxymethyl cellulose solves the common challenge of achieving desired consistency without affecting flavor. It acts as a fat replacer in low-calorie products and improves freeze-thaw stability in frozen foods, thus extending shelf life and reducing waste.

In pharmaceuticals, sodium CMC is used to overcome the difficulty of tablet disintegration and controlled drug release. As noted by pharmaceutical developer Dr. Suresh Patel, “sodium carboxymethyl cellulose ‘s binding properties ensure that tablets not only hold together properly but also break down correctly once ingested, which is crucial for patient compliance and drug efficacy.”

For the cosmetic industry, maintaining product homogeneity and stability can be challenging due to the diverse range of ingredients used. Sodium carboxymethyl cellulose addresses this by acting as a stabilizer, ensuring that products retain their intended quality over time.

In technical applications such as paper production and textile manufacturing, sodium carboxymethyl cellulose improves product strength and durability. This is critical in industries where the quality and longevity of materials are paramount. Industrial chemist Dr. Lara Gilbert states, “The film-forming ability of sodium carboxymethyl cellulose contributes significantly to the tensile strength of paper products, enhancing their durability.”

Eco-Friendly Alternative

Moreover, sodium carboxymethyl cellulose ‘s biodegradable nature offers an eco-friendly alternative to synthetic polymers, which is becoming increasingly important in industry and consumer products. This aspect of sodium CMC is particularly appealing in an era where environmental impact is a significant concern.

Overall, sodium carboxymethyl cellulose is chosen by various industries not only for its functional benefits but also for its contribution to sustainability and product performance enhancement. It provides effective solutions to some of the most pressing challenges faced by manufacturers, affirming its status as an indispensable polymer in modern applications.

In our exploration of Sodium CMC , we’ve uncovered its critical role as a multifunctional agent playing a silent yet impactful part in various industries. As a thickener in foods, a stabilizer in pharmaceuticals, and a strength enhancer in paper products, Sodium CMC ‘s versatility is unparalleled. Its ability to solve industry-specific challenges, such as improving the texture of gluten-free foods or the longevity of cosmetic products, makes it a valuable asset in manufacturing and product formulation.

The significance of Sodium CMC lies not just in its varied applications but also in its contribution to the quality and sustainability of products we use daily. We invite readers to reflect on this content and share their thoughts on how the versatility of CMC might impact their perspective on product formulation and usage.

In summary, sodium carboxymethyl cellulose stands as an exemplary polymer, vital for its binding, thickening, and stabilizing abilities, which are essential to the structural and functional integrity of countless products. This exploration into the world of sodium CMC illustrates the profound influence that one polymer can have across a diverse array of applications.

Insights on Sodium Carboxymethyl Cellulose: Answering Your Questions

What are the primary uses of sodium carboxymethyl cellulose in food products?

Sodium CMC is primarily used as a thickener, stabilizer, and emulsifier in food products. It helps maintain the desired texture and consistency in items like ice cream, non-dairy milk, sauces, and baked goods.

Can Sodium Carboxymethyl Cellulose be found in pharmaceutical products?

Yes, sodium carboxymethyl cellulose is often utilized in pharmaceuticals as a binder in tablet formulation, helping to ensure that tablets break down correctly in the body. It is also used to stabilize suspensions and emulsions in medicinal syrups and creams.

Is sodium carboxymethyl cellulose different from carboxymethyl cellulose?

Carboxymethyl cellulose is the base polymer, and when it is in its sodium salt form, it is referred to as sodium carboxymethyl cellulose or Sodium CMC . The sodium form is more soluble and often used in applications where rapid dissolution is required.

What role does Sodium Carboxymethyl Cellulose play in the cosmetics industry?

In the cosmetics industry, sodium carboxymethyl cellulose acts as a stabilizer and thickener. It is used to improve the texture and consistency of products like lotions and creams, ensuring they are smooth and easy to apply.

Are there any non-food or non-pharmaceutical uses of Sodium Carboxymethyl Cellulose ?

Yes, sodium carboxymethyl cellulose has applications beyond food and pharmaceuticals, including serving as a sizing agent in textiles and as a paper product enhancer, where it contributes to paper strength and printability.